Main characteristics/functional differences due to differences in the structure of various isolators

This page compares and introduces the characteristics of each digital isolator architecture.

When comparing characteristics, it is important that the comparisons are made under the same measurement conditions. (Please note that even if the specifications are the same on the data sheet, the conditions may be slightly different.) Here, the data measured under the same conditions are compared. For comparison, we use SKYWORKS general digital isolators Si84xx and Si86xx.

emission

I compared the emissions of various isolators. Emissions generated by devices are a major problem for systems. Note that this characteristic also changes depending on the direction of measurement. One of the causes of emissions is when an electric field is generated between the 1st and 2nd GND because there is no return path for the transmitted signal. The SKYWORKS isolator performs signal transmission differentially, has a current return path inside the device, and the signal is very small, so the possibility of generating noise is very small.

Emission data for SKYWORKS Si8442. The carrier wave is around several hundred KHz, but the influence of the emission is not seen.

This is data from another company using the same CAPACITIVE method. Emission seems to be high near the frequency that seems to be the carrier wave.

Product data transmitted on a coil basis. Emissions near what appears to be the carrier frequency appear to be higher.

Products with low EMI are required for applications such as information equipment and medical equipment.

[Reference material]

Low EMI Isolation for Medical Equipment Applications

AN1131: Design Guide for Reducing Radiated and Conducted Emissions in Isolated Systems Using Skyworks' Isolators

Isolator vs. Optocoupler Technology

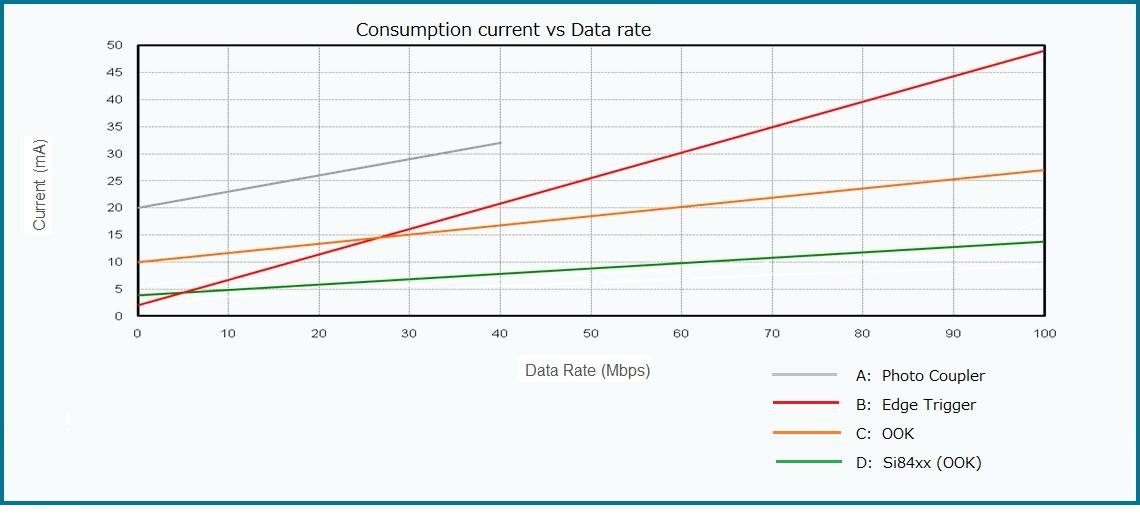

Differences in current consumption and signal communication method (OOK: On-Off-Keying vs Edge Trigger)

We compared the current consumption of various isolators. Here we will compare the difference in current consumption and signal communication method (OOK: On-Off-Keying vs Edge Trigger).

With edge-triggered technology, the current consumption rises with the frequency of the input on both the input and output sides. Therefore, if the input frequency is low, the current consumption can be reduced.

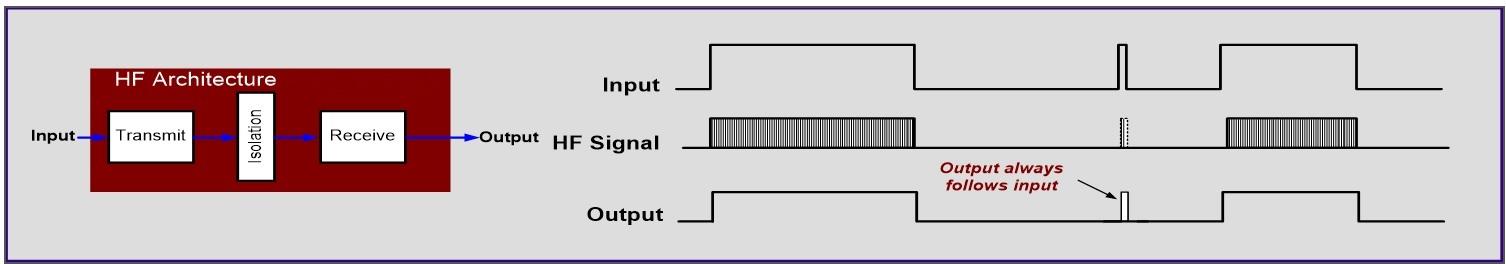

On the other hand, the circuit current on the primary side of OOK (On-Off-Keying) depends on the duty of the signal. The current on the secondary side increases depending on the load and frequency. When it is ON, the carrier wave is continuously sent, so the current consumption is high, but because it is resistant to noise, products using OOK are the mainstream in applications with a lot of disturbance noise, such as automotive products and motors. SKYWORKS isolators are excellent products with low current consumption and data rate of 150MHz while being OOK.

The OOK (On-Off-Keying) method controls the output by sending a signal only when the input is High (or Low). A photocoupler is a similar control method. The good point of this method is that even if the output changes due to disturbance, it recovers immediately. In some SKYWORKS products, there is anoption to send the carrier wave in High or Low depending on the bias of the signal so that the current consumption can be further reduced.

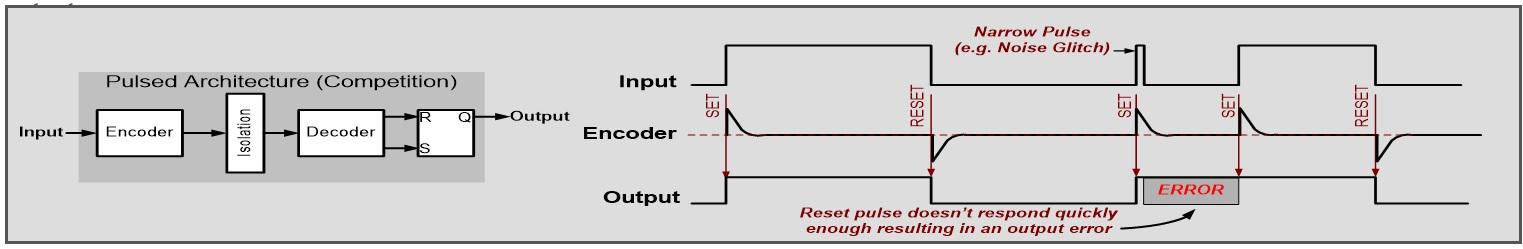

On the other hand, the edge trigger method seen in other companies' digital isolators changes the output state by looking at the input transition (H→L/L→H). Since the current consumption changes according to the input frequency, it is possible to reduce the current consumption, especially when performing low-speed signal communication. In order to communicate the transition signal normally, a filter is provided to prevent disturbance from entering, but there is still a possibility that disturbance will enter, and it may lead to malfunction such as the output being inverted as shown in the left figure. . There are certain countermeasures such as periodically sending a status signal on the input side or sending a different signal on the rising/falling edge, but caution is required in noisy applications.

Effects of electromagnetic fields

We compared the effects of electromagnetic fields on various isolators. In actual equipment, electromagnetic fields also affect wiring, etc., so care must be taken during design and evaluation. Standard digital isolators (such as Si84xx and Si86xx) are highly immune to electromagnetic fields and support tamper-proofing of electricity meters. They are resistant to electric fields of 300V/m and magnetic fields of 1000A/m and above.

magnetic field effect

This graph compares the effect on the magnetic field (magnetic flux). It seems that certain characteristics have been cleared in measurement standards such as IEC 61000-4-8, which is an immunity test for 50 Hz/60 Hz power frequency magnetic fields, and IEC 61000-4-9, which is a pulse magnetic field immunity test. The products appear to be particularly resistant to magnetic fields.

Effect of electric field

This graph is the result of applying an electric field with varying frequencies and monitoring the output. The SKYWORKS Si84xx was unaffected by fields of 300V/m up to 10GHz. However, this model of magnetic coupling method seems to react to the electric field around 1GHz (1000MHz).

Products that are resistant to electromagnetic fields are required in environments where cables with large currents, which are common in applications such as automotive products and large power equipment, are nearby.

[Reference material]

Low EMI Isolation for Medical Equipment Applications

CMOS Digital Isolators Supersede Optocouplers in Industrial Applications

Isolator vs. Optocoupler Technology

Summary

Several decades have passed since the digital isolator came out into the world, and it has come to be used in many products. The input/output delay time is much shorter than that of a photocoupler, and the characteristic that there is little variation due to temperature changes plays an essential role in increasing the efficiency of the system.

Even among various digital isolators, there are differences in emissions, current consumption, etc., as described above, due to differences in structures such as capacitive insulation and magnetic insulation, and differences in communication methods such as OOK (On-Off-Keying) and edge triggers.

The SKYWORKS isolator is one of the oldest digital isolators produced and has very good characteristics. If you are looking for an insulating element, please consider it.

Information on the product introduction page

Here is the product introduction page of the digital isolator with the above architecture/features.

Inquiry

If you have any questions regarding this article, please contact us below.

To Sky Works Manufacturer Information Top

If you want to return to Skyworks' manufacturer information top page, please click below.