1608 size white chip LED ensures the highest reliability in the industry

ROHM has released the 1608 size (1.6mm x 0.8mm) white chip LED "SMLD12WBN1W" for display panels of industrial equipment and small equipment. The SMLD12WBN1W achieves both long life and high mountability by adopting a new material for the sealing resin.

In recent years, small white LEDs have been increasingly used in industrial equipment and consumer equipment as numeric displays and indicator light sources for panel displays to improve design and visibility. There is a demand for highly reliable LEDs that do not "degrade in luminosity" due to energization even when used.

Until now, ROHM had prepared a lineup of 1608 chip LEDs ranging from red to green, but in order to meet these market demands, we were developing a highly reliable white chip LED. This time, by newly adopting a hybrid resin that combines the properties of both epoxy resin and silicone resin, we have added a 1608-size white chip LED that has the highest reliability in the industry to our lineup.

Solving white LED issues with new materials

Epoxy resin or silicone resin is generally used for the molding part in white LEDs with the high luminous efficiency of the “blue LED + yellow phosphor” method. However, there are problems with the characteristics of each resin material, such as "degradation of light intensity" with epoxy resin and "strength of mold during mounting" with silicone resin.

On the other hand, the new material used in SMLD12WBN1W can solve both issues of long life and high mountability.

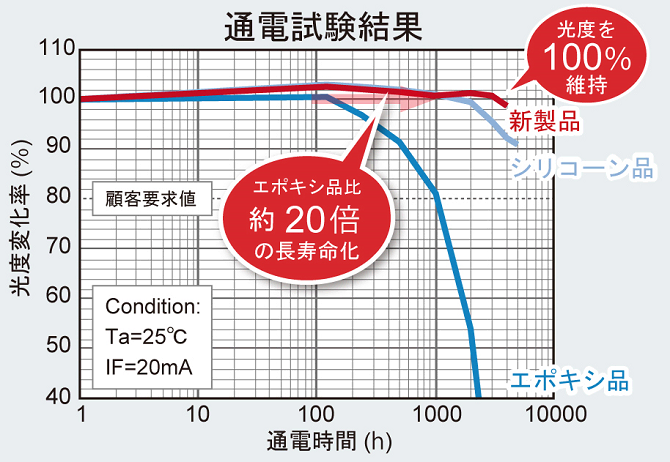

Succeeded in maintaining 100% luminous intensity even after 1000 hours of energization

In the past, the red and green LEDs used in the display panels of industrial equipment were less susceptible to yellowing of the resin due to light energy, and luminosity deterioration was not considered a problem. On the other hand, in white LEDs, epoxy resin is generally used for the molding part, but short-wavelength (λD: ~527nm) LEDs, including white, have the problem that the resin turns yellow due to light energy. was.

By adopting a new resin, the newly developed LED successfully maintained 100% luminous intensity during a current test (25°C, IF=20mA, 1,000 hours of current). When compared with epoxy products with the same residual luminous intensity, it can achieve about 20 times longer life.

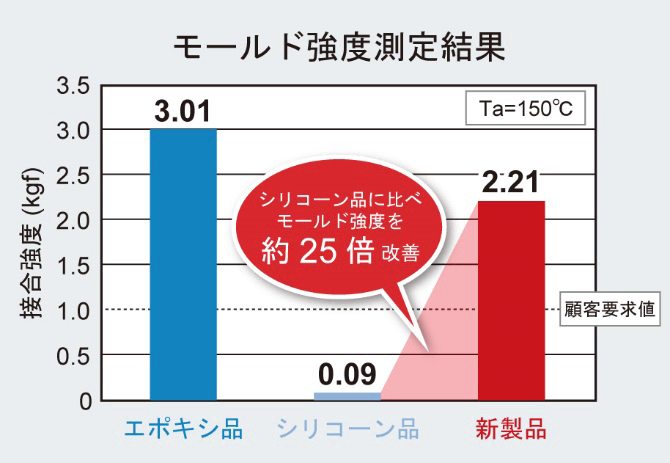

Approximately 25 times better mold strength than silicone resin

Luminous intensity deterioration can be improved by using silicone resin, which is used in LED lighting. Therefore, the destruction of the mold part was a problem.

By adopting a new resin, the mold strength, which determines mountability, has been improved by about 25 times compared to silicone resin products under high temperature conditions (Ta=150°C). As a result, defects during mounting are less likely to occur, and high mountability can be achieved.

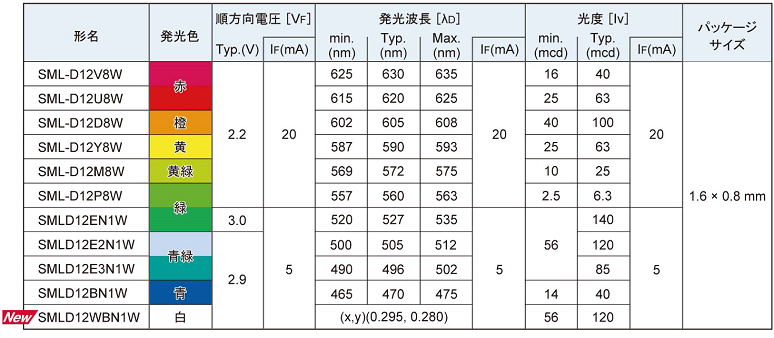

Line up

In addition to the white LED (SMLD12WBN1W), red to green LEDs are available, so you can choose the LED that matches your application.

Application example

- industrial equipment

- small consumer electronics

- amusement

For those who want to know more about our products

If you would like more information about any of the products mentioned in this article, please contact us here.