Newly developed G-type package product added to lineup

SiC (silicon carbide), which is expected to be a next-generation low-loss element to replace silicon semiconductors, is evolving day by day.

ROHM has been working on the development of SiC power devices and modules ahead of the rest of the world, and now we have added to our lineup a full SiC power module that employs a newly developed G-type package that achieves an inductance of only 10nH and low thermal resistance. So let me introduce you.

Suitable for high power applications, high rated current 400A, 600A products added

High rated current 400A and 600A products have been added to ROHM's full SiC power module BSM series lineup. This makes it possible to consider further high-power applications such as large-capacity power supplies for industrial equipment, mega solar, and UPS.

| Product name | Absolute maximum ratings (Ta=25°C) | inductance (nH) |

package | thermistor | ||||

| VGS (V) |

ID (A) [Tc=60°C] |

Tj max (℃) |

Tstg (℃) |

Visol (V) [AC 1min.] |

||||

| BSM080D12P2C008 | -6~22 | 80 | 175 | -40~125 | 2500 | 25 | C type 45.6 x 122 x 17mm |

- |

| BSM120D12P2C005 | 120 | |||||||

| BSM180D12P3C007 | -4~22 | 180 | ||||||

| BSM180D12P2E002 | -6~22 | 180 | 13 | Type E 58x152x17mm |

○ | |||

| BSM300D12P2E001 | 300 | |||||||

| NEW BSM400D12P3G002 |

-4~22 | 400 | 10 | G Type 58 x 152 x 17mm |

||||

| NEW BSM600D12P3G001 |

600 | |||||||

Two reasons for adding 400A and 600A products

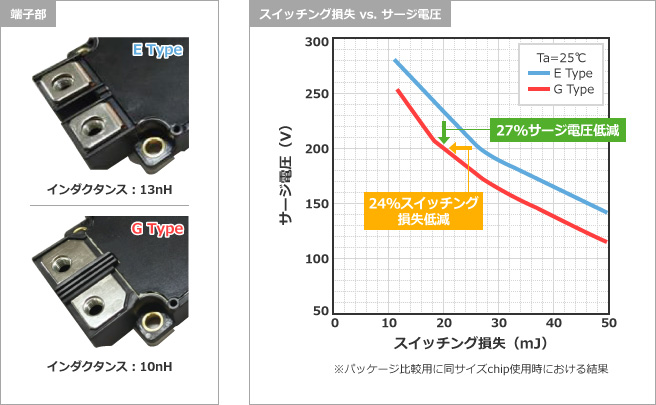

1. Reduction of inductance

Power modules with high current ratings have very high surge voltages during switching due to package parasitic inductance. When increasing the current of a full SiC power module, it is necessary to reduce the parasitic inductance to keep this surge low in order to make the most of the high-speed switching performance that is a feature of SiC power devices.

The newly developed G type package has an internal inductance that is approximately 23% lower than the conventional package (E type) by optimizing the layout, wiring pattern, and terminal structure of the embedded SiC device. It has been.

As a result, the surge voltage can be reduced by 27% compared to the conventional package, and full SiC power modules rated at 400A and 600A have been commercialized. In addition, under similar surge voltage conditions, the new package can reduce switching losses by 24%.

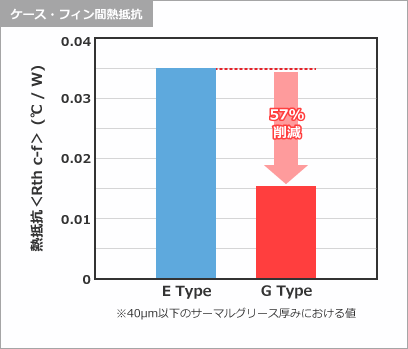

2. Reduction of thermal resistance

Another point of improvement is that the flatness of the heat dissipation surface of the package has been greatly improved through proprietary processing in order to improve the connection to the cooling mechanism. In order to achieve a large current of 600A, in addition to reducing internal inductance, high heat dissipation performance is also required.

In the G type package, by improving the flatness of the base plate, which greatly contributes to the heat dissipation performance of the module, the thermal resistance between the base plate and the external heat sink or cooling mechanism has been reduced by 57%.

This will reduce the thermal resistance between the case and the fins when used by the customer.

Application example

- Power inverter for industrial equipment

- PV inverter

- motor drive

At the end

SiC (silicon carbide) is expected to be a next-generation low-loss element.

Please look forward to ROHM's efforts to develop SiC power devices and modules ahead of the rest of the world.

Click here for recommended articles/materials

Two advantages of using a full SiC power module with SiC-MOSFET and SiC-SBD

The favorite for power devices is SiC (silicon carbide)

High efficiency and miniaturization of heat dissipation parts! What is a 1700V withstand voltage isolated power supply "SiC+AC/DC"?