There's an old adage in the engineering world: "If it moves, it will break." We all know that mechanical things like fans and relays are usually the first to fail. Any critical system should have a proactive maintenance or replacement program for these items, just in case. It is even worse if those mechanical parts normally operate at high stress levels and must react reliably in an emergency, for example a contact breaker in series with an electric vehicle battery. .

Under these circumstances, the operating current can be hundreds or thousands of amperes in the closed state where the breaker must be opened. The voltage is high, typically 400V DC or higher, and the inductance of the connection makes the spike voltage even higher when the fault current is interrupted. This voltage causes an arc that vaporizes the breaker contacts. Also, since it is direct current, it does not have a zero cross to extinguish an arc like alternating current does. Breakers are also slow to open and close (tens of milliseconds), which can result in damaging penetrating energy in short-circuit conditions.

Also, the older the breaker, the slower it works and the more lossy it gets. The life of high current mechanical circuit breakers is critical, so they must be ruggedly built, sometimes using puffs of compressed gas or magnetic "blowout" coils to eliminate arcing. Special methods are sometimes used.

| Features | solid state breaker (Si/SJ/SiC/IGBT/IGCT) |

electromechanical breaker |

| Full controllability | ☆☆☆☆☆ | ☆☆☆ |

| High speed | ☆☆☆☆☆ | ☆☆ |

| Conduction loss | ☆☆ | ☆☆☆☆☆ |

| No arcing | ☆☆☆☆☆ | ☆☆ |

| Use cycles : no maintenance | ☆☆☆☆☆ | ☆☆ |

| Cost per amp | ☆☆ | ☆☆☆☆☆ |

| Voltage rating vs. on Rds(on) | ☆☆☆ | ☆☆☆☆☆ |

Naturally, solid state circuit breakers (SSCBs) have been designed as an alternative and manufactured using all available semiconductor technologies such as MOSFETs, IGBTs, SCRs, IGCTs, and are less susceptible to arcing and mechanical wear. You have successfully solved the problem. For example, in the case of an IGBT, a voltage drop of 1.7V occurs at 500A, consuming 850W of power. IGCTs have a low voltage drop, but are very large in physical size. MOSFETs do not exhibit a "knee" voltage like IGBTs, but they do have on-resistance.

Improving the MOSFET would require this RDS(on) to be less than 3.4mΩ to achieve a voltage rating greater than 400V, which is currently not possible with a single MOSFET. Many MOSFETs in parallel are possible, but the cost jumps and doubles if bidirectionality is required. Electromechanical circuit breakers aren't cheap, but they still have a cost advantage.

Is there any difference with SiC?

So can the new marvel of wide-bandgap semiconductors fill this gap? Silicon carbide switches have about 1/10 the on-resistance of silicon in the same die area, and have much better thermal conductivity, allowing them to withstand twice the maximum temperature.

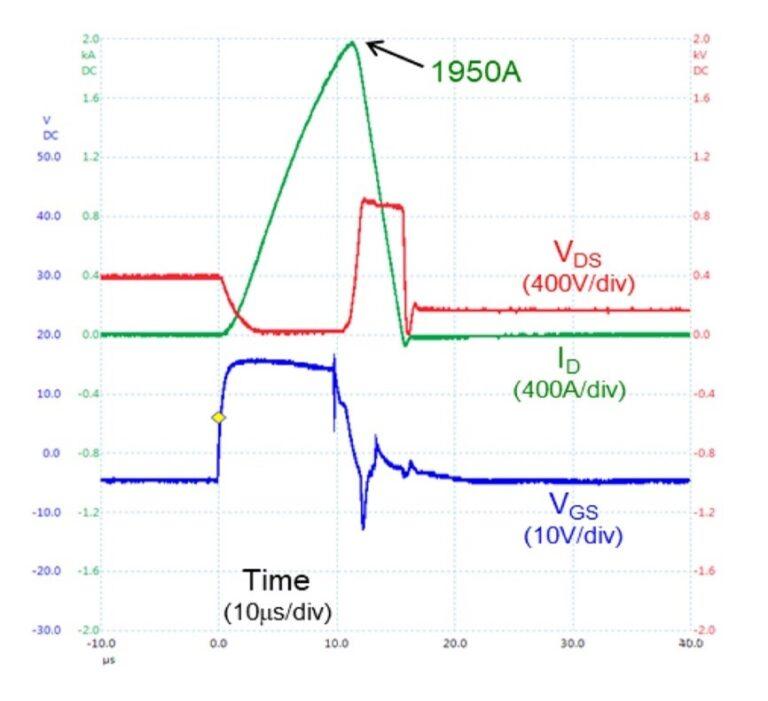

This opens up the possibility of putting enough dies in parallel in a small package to improve the IGBTs used as SSCBs.SiC FETswould be an ideal candidate. Cascoding of SiC JFETs and Si-MOSFETs is easy to drive and one of the best switch technologies available today.RDS(on)It has a figure of merit of ×A. Qorvo demonstrated SSCB by placing six 1200V dual gate dies in parallel to achieve 2.2mΩ on-resistance at 1200V 300A rating in SOT-227 package. As shown in Figure 1, this prototype safely shuts off nearly 2000A of fault current.

Bringing the internal JFET gate out to a separate pin allows for more direct control of the edge rate in fast switching applications, effectively enabling normally-off or normally-on operation as desired in some applications such as SSCB. can be selected to The on-resistance is also slightly improved by slightly positively biasing the gate of the JFET. However, there is another feature: at positive voltages of 2V and above, the channel is fully conducting and the gate looks like a forward-biased diode. Given a constant low current through it, the actual knee voltage of the diode will have an exact relationship to the temperature of the die. Measuring this and recording temperature trends can be used for rapid overheating detection and even long-term health monitoring.

SiC FET SSCBs are on the right track to replace mechanical contacts

SiC FETs will allow SSCB applications to handle higher currents and losses will continue to decrease as technology advances. Devices can be paralleled to achieve ultimate loss on par with mechanical circuit breakers, and cost is not necessarily an issue as die improvements reduce the number needed for a given resistance. . In addition, the cost of SiC wafers is said to be halved in the next few years, and economies of scale can be expected from the expansion of the circuit breaker market due to the sale of electric vehicles. Moreover, this argument becomes even more compelling when considering the maintenance and replacement costs of electromechanical solutions.

An engineer's maxim is, "If it ain't broken, don't fix it." Instead of waiting for it to break, why not consider SiC FET SSCBs as a worry-free solution?

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.