How to improve efficiency with SiC semiconductors

Industry is finding that server farms will account for 1% of the world's energy demand, and efficiency gains translate into significant cost savings and environmental impacts by a few percentage points. Efficiency gains may reach a "tipping point" where the benefits begin to multiply. For example, in electric vehicles, improvements will make power converters smaller and lighter, reducing energy demand and increasing range.

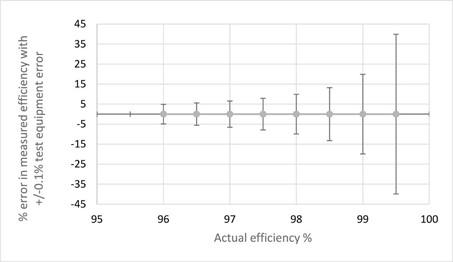

So engineers are obsessed with improving efficiency beyond the decimal point. Determine if the risk of designing in a new and unfamiliar topology with the promise of often marginal improvements results in a lower total cost on any given timescale. The more efficient you are, the harder it is to convince yourself that there is an improvement. Even if there is a ±0.1% error in the input and output power measurements, the calculated losses can be 40% more or less than the actual value if the efficiency is already around 99.5%. I have. Worse if the input is AC with a distorted low power factor and the output is DC with a residual noise component that confuses the DVM. It is now common to rely on calorimetry, which actually measures heat output, rather than inferring it from electrical measurements.

One relatively low-risk option for increasing the efficiency of power converters is to improve already designed semiconductors. MOSFET-based converters can be upgraded with newer devices that have lower on-resistance and require less switching energy, and changes in EMI emissions must also be considered. However, to take advantage of modern wide-bandgap devices such as SiC MOSFETs and GaN HEMTs, circuit modifications, especially gate drives, are required. If existing circuits are IGBT-based, they will need to be redesigned from scratch to use wide bandgap devices.

The gate drive issue has to do with voltage levels. Full-featured SiC MOSFETs require much higher on-voltage drive than Si-MOSFETs, which must be carefully limited as they are much closer to the device's absolute maximum ratings. In addition, since the voltage swing between the ON and OFF states is large, the gate capacitance is charged and discharged in each cycle, requiring a certain amount of driving power. Also, the threshold voltage varies and has hysteresis, making it difficult to drive optimally. GaN HEMTs, on the contrary, have very low gate threshold voltages and absolute maximum values, requiring careful control of the drive circuit to avoid overloading or failure.

If the power conversion circuit requires reverse or third-quadrant conduction, the body diode characteristics of SiC MOSFETs are important, and their large recovery energy and forward voltage drop can lead to excessive losses. there is. GaN devices do not have a body diode and conduct in reverse through the channel, but have a high dead-time voltage drop before the channel is actively enhanced by the gate drive. When the gate is driven negative in the off state, the drop during "commutation" is even greater.

In order to overcome this situation, the Si-MOSFET and SiC JFET are cascode-connected. SiC FETs is valid. This device, like a Si-MOSFET, Gate drive is easy and non-critical have better figures of merit than SiC MOSFET and GaN HEMT cells RDS(on) xA and RDS(on) x EOSS is equipped with Strong intrinsic avalanche capability and self-limiting short-circuit current, body diode effect similar to low voltage Si-MOSFET, low forward drop and fast recovery. In other words, SiC FETs can instantly improve efficiency by simply dropping them into a Si-MOSFET or IGBT socket. The speed of SiC FETs is such that EMI and stress cannot be suppressed by simply adjusting the gate drive resistor like other technologies, but overshoot and ringing can be reduced to a small size in this ultra-high speed device. RC snubber can be effectively suppressed at , and parallel operation of devices is also facilitated. In addition, by replacing IGBTs, it is possible to increase the switching frequency without generating switching loss, and the size, weight, and cost of the magnetic circuit have been reduced.

SiC FETs are a promising way to improve the efficiency of common conversion topologies, with all the benefits that come with it.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.