Feedback in the design flow is important. Engineers always choose which device to use while looking at the balance between cost and performance. In the process, we actually conduct evaluations, simulations, etc., and provide feedback on our confident designs.

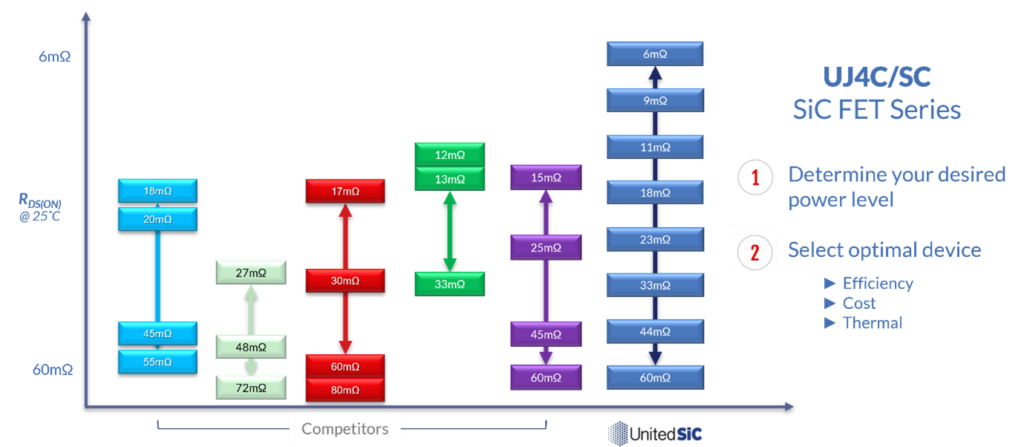

However, the lack of options makes it very difficult to choose the best device. Last year, the company led the market with 18mΩ and 60mΩ devices, but there are applications out there that demand even lower resistance values, and those that require resistance values in between. It also depends on your budget for each application. Using the lowest on-resistance device takes the least layout area and requires the least amount of assembly steps, but costs less when paralleled lower-cost components yield the same resulting on-resistance. There is a possibility that it will be It is also very advantageous from the viewpoint of heat dissipation.

Gen4 SiCFET series

To provide design flexibility, Qorvo offers additional Gen4 750V SiC FETs with on-resistances of 23, 33, and 44mΩ and 6, 9, and 11mΩ parts. As a result, devices with different on-resistances can be “mixed together” to get the best price/performance combination for specific thermal and operating conditions. You can also take advantage of pricing when you increase flow by using lower cost parts in common across different designs.

SiC FETs are easy to parallelize and their gate drive power is so low that the extra energy from paralleling is usually negligible. The device is naturally current balanced due to the positive temperature coefficient of the on-resistance. For example, two in parallel at 18mΩ will result in less total conduction loss compared to a single 9mΩ device. This is because halving the current in each of the two devices halves the power in each, resulting in lower temperature rise and proportionally less rise in on-resistance. A lower junction temperature naturally improves reliability and provides more headroom below the already high SiC maximum.

Using the Qorvo "FET-Jet Calculator", you can set any number of SiC FETs in parallel for different applications and operating conditions and see the actual losses and temperature rise effects.

Gen4 SiC FET leads the industry

Gen4 SiC FET products offer best-in-class performance, including wafer thinning to reduce thermal conduction losses to the substrate and reduced junction-to-case thermal resistance, resulting in lower junction operating temperature. It uses 4th generation advanced manufacturing techniques such as silver sinter die attach to lower the . These products are available in TO-247 3-lead packages as well as 4-lead packages if a source "Kelvin" connection is desired. Figure 1 summarizes how the new 750V SiC FETs are positioned relative to their SiC MOSFET competitors.

Qorvo's 750V SiC FET portfolio has the flexibility of having a wider range of choices for many applications. Qualified for automotive AEC-Q101, these products are used in traction inverters, on-board and off-board chargers, and DC/DC converters for increased efficiency and improved voltage margins compared to 650V rated components. , and can be used for wireless charging. The ultra-low resistance also makes it useful for AC/DC solid-state circuit breaker applications where low conduction losses are important for efficiency and miniaturization. In general, in industrial and IT power conversion products, Gen 4 SiC FETs improve performance in both hard-switching and soft-switching topologies.

Based on customer needs, Qorvo optimizes frequency compensation, responds quickly, and offers more options.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.