The road to the EV revolution is paved with SiC

Silicon carbide semiconductor switches have many properties that make them serious competitors to replace IGBTs in EV inverter applications. However, the conduction loss is the same at high current and rated voltage. However, the latest generation SiC cascode breaks this barrier with its ultra-low on-resistance.

When Dorothy and Toto followed the yellow brick road, it may have been paved with silicon carbide (rainbow yellow crystals). SiC can be green or bluish-black, but that would ruin the trope. It would have been pretty good for grip and durability - its alias is carborundum.

In the modern version of the story, characters might travel to the Emerald City in electric vehicles, but in the real world, market adoption of EVs is hampered by price and limited mileage. But there is demand for a zero-carbon emission future for transportation. Initiatives such as EV30@30 to reach 30% market share for EVs by 2030 are challenging, but advances in power conversion components are making the switch to EVs more difficult in terms of driving range, affordability, and running costs. becomes more viable. While battery and motor technology advances, conversion efficiency, size, and cost of motor-driven electronics remain important. Every percentage point of efficiency gained contributes to a virtuous cycle of less load on the battery, less heat dissipation, smaller size and less weight, resulting in longer driving range on a single charge. help.

This is where SiC comes into play, not as a road surface, but as a semiconductor switch. First generation EVs used only IGBTs as switches. It is a mature technology that has been tried and tested for decades and has proven to be robust and reliable. Many parallel lead packages are used, such as Tesla models, but IGBT modules are also being considered. Motor drive IGBTs do not need to switch at high frequencies, but they also have slow switching edge rates and consume a lot of power at each transition. Si-MOSFETs are significantly better at nanosecond slew rates, but this is a problem as they have limited power ratings and EV peak power is now measured in fractions of megawatts. . However, SiC has the speed and low on-resistance to handle the hundreds of amperes typically involved. Early generations still dissipated significant I2R power, especially with high on-resistance for high-voltage rated components, but the latest generation achieves less than 10mΩ even with a 1200V rating, making it suitable for next-generation EVs with 800V batteries. .

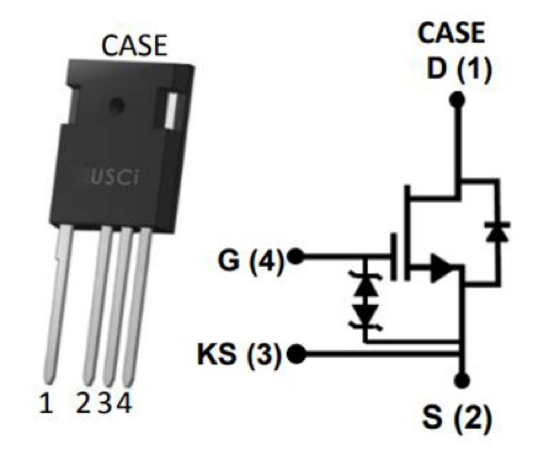

As an example, in the third generation of Qorvo's UF series SiC switches, the UF3SC065007K4S is rated at 650V and 6.7mΩ and the UF3SC120009K4S is rated at 1200V and 8.8mΩ. There are also 16mΩRds(on) parts with a 1200V rating for low power applications. All devices are offered in TO-247 packages with 4-pin Kelvin connections for optimal gate drive.

These are cascodes that combine SiC JFETs and Si-MOSFETs, making it easy to drive the gates of MOSFETs while maintaining the switching performance of SiC. Since the required gate drive voltage is compatible with MOSFETs and IGBTs, the efficiency performance can be improved instantly without rebuilding the entire power platform, making the device compatible with existing applications using TO-247 IGBTs. may drop in. More benefit can be gained from tweaking the components around the inverter, for example by reducing the size of the snubbers and removing the parallel diodes in the IGBTs, as cascodes inherently have a high performance body diode effect. can do. Efficiencies over 99% are easily achieved with this process. Less power loss means smaller heatsinks, cheaper, lighter and better balance.

SiC cascode reliability is excellent, with proven high-energy avalanche ratings and self-limiting of peak currents as the device heats up to withstand short circuits. The inherent high-temperature behavior of wide-bandgap materials also provides reassurance, as the 175°C continuous junction temperature specification allows for higher peak values.

Once the land of Oz declares zero emissions, the yellow SiC crystals will definitely be in Dorothy's EV as well as pave the road.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.