Qorvo Low RDS(on) SiC FETs Deliver Unparalleled Efficiency

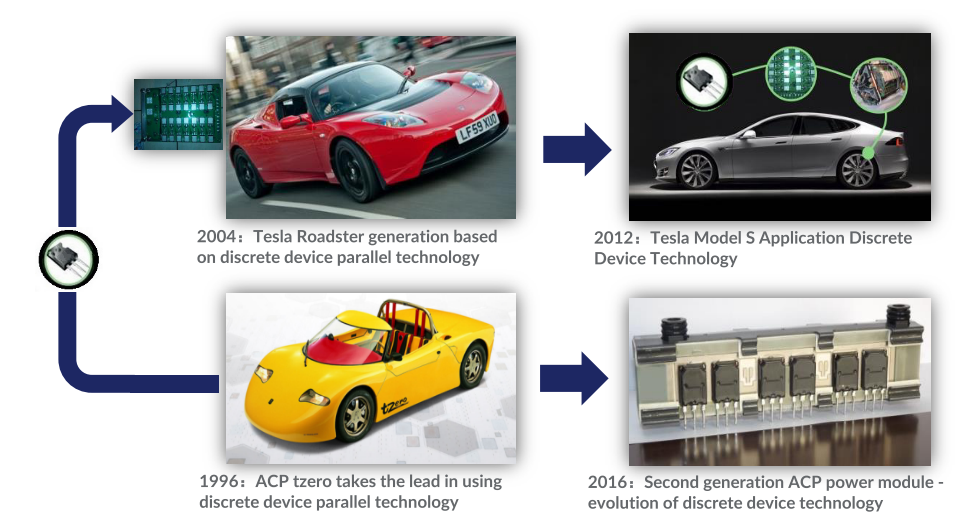

AC Propulsion develops electric vehicle technology and provides products and engineering services to automotive and other clients worldwide. When developing a second-generation power module for its own low-cost drive unit inverter, AC Propulsion needed a power semiconductor that would deliver 2-5% higher switching efficiency compared to existing IGBT-based designs. did.

solution

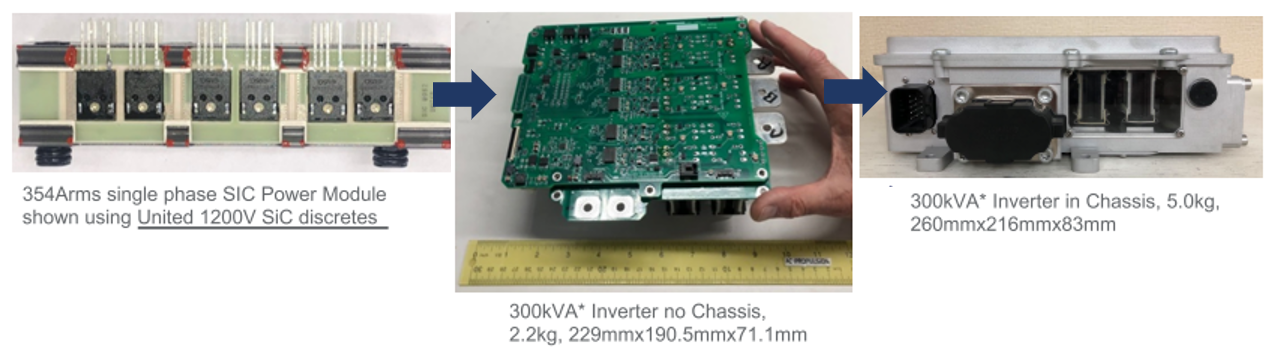

A 3-phase AC traction inverter for EVs, designed by AC Propulsion using Qorvo UF3SC120009K4S, 1200V, 9mohm SiC FETs, offers improved efficiency over competing SiC devices. It is also packaged in the common TO-247 package, making it a more efficient and cost-effective drop-in replacement.

merit

With a low RDS(on) of 9mΩ, new high-performance power module designs use fewer discrete components, saving system cost and space. Its efficiency allows you to use a self-contained heatsink while still delivering great performance.

Using Qorvo FETs and IGBTs improves drive cycle efficiency by 3%-5%. This means that the range could be increased and the battery size could be reduced.

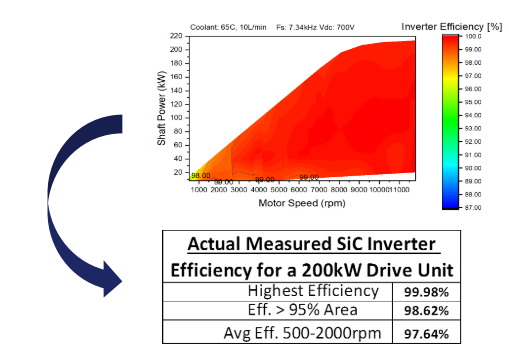

■ Performance data

■ Practically measured SiC inverter efficiency for a 200kW drive unit

|

Highest efficiency |

99.98% |

|

Eff. > 95% Area |

98.62% |

|

Avg Eff. 500-2000rpm |

97.64% |

Note: SiC inverter for 300kVA. 99% efficiency and 295Arms/phase at 700VDC input used for 222kW shaft output power PM motor in efficiency map shown

Click the button below to download the PDF version.

Products used in this case study

You can check the products used in this case here.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.