What engineers face in the real world

Automotive engineers are being forced to make a radical shift away from electro-mechanical engineering as the pace of automobile invention accelerates faster than Henry Ford could have imagined. With consumer demand and industry focus moving towards hybrid and fully electric vehicles, this shift will be felt more strongly, pushing engineers to go beyond "business as usual" to drive high-current, high-voltage electric vehicles. Innovative solutions will be required for problems such as power line disconnection.

Possibilities of SiC semiconductors in solid state breakers

Some vehicle designs are still from the 1980s, even for electric vehicles, and electromechanical switches and contactors are still used to interrupt high currents and disconnect the power rail in the event of a fault. However, with thousands of amps expected and battery voltages above 800V, mechanical options become complex and difficult. Wear is a problem because interrupting DC produces an arc of length proportional to voltage and strength proportional to current. The contact material burns off, and the heat from the arc degrades the entire part. Special measures such as injecting oil or blowing out the arc with compressed air can be used to extinguish the arc, but the problem is exacerbated by higher current and voltage levels. In addition, because breakers and contactors are mechanical devices, they are susceptible to shock and vibration, which are particularly problematic in the automotive environment, and operate relatively slowly, on the order of tens of milliseconds.

Solid-state breakers are available using GTOs, IGBTs, and more recently MOSFETs, but they have high insertion loss, can dissipate tens of watts of power in the device under normal operating conditions, and heat the components. stress and reduce system efficiency.

However, the latest SiC (silicon carbide) switches are opening up new possibilities. A switch configured as a breaker operates within 100ns to a few us to avoid arcing. Qorvo's new parts such as UF3SC065007K4S (650V, 6.7mΩ) and UF3SC120009K4S (1200V, 8.6mΩ) have minimal conduction losses and operate reliably at 175°C continuous junction temperature. It can have even higher peak ratings. SiC switches in TO-247 packages are cascaded SiC JFETs and Si-MOSFETs with non-critical gate drive for easy integration into new designs or using MOSFETs and IGBTs It can also be used as a replacement for existing discrete solid state breaker designs.

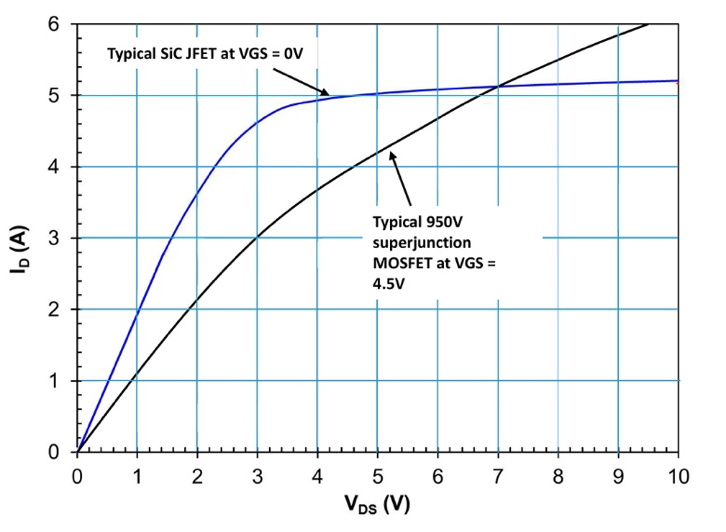

Compared to mechanical breakers, solid-state switches with SiC cathodes also enable other functions. For example, you can control conduction to limit inrush current or precharge a capacitor. The short-circuit current can be limited by the "pinch-off" effect of the JFET, and the saturation current, which decreases with increasing temperature due to increased electron mobility, is well controlled (Figure 1).

Also, in the off state, SiC semiconductors have a high energy avalanche rating and withstand voltage transients well.

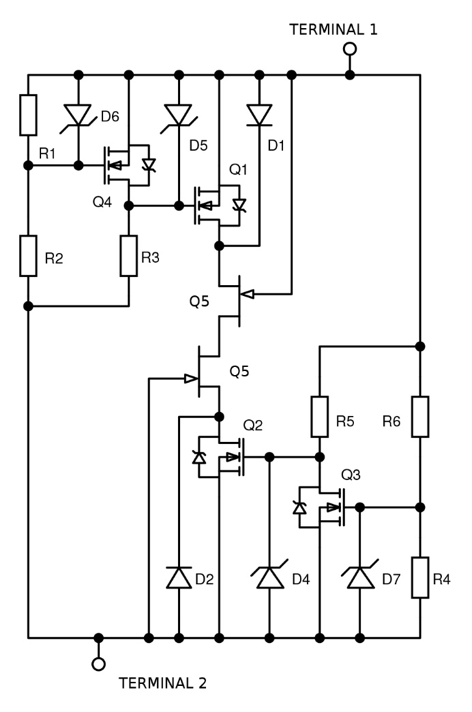

SiC cascodes are intended for compatibility with MOSFET and IGBT gate drives, so they require a positive Vg to saturate. From Qorvo there is also a SiC JFET that is normally on, i.e. conducts at Vg=0V. This opens up the possibility of a true two-terminal circuit breaker module without the need for external auxiliary power rails or internal DC-DC converters (Figure 2).

Touch screen displays and electronic switches have become standard in modern automotive design and there is an increasing trend to eliminate moving parts. Introducing a highly efficient and robust solution for switching high voltages and currents in drive and battery systems using Qorvo's SiC cascodes.

The use of solid-state circuit breakers, switches, and current limiters using SiC semiconductors is another opportunity for engineers to split the infinitive and “go bold” toward next-generation EV designs.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.