SiC power switches chosen to pursue even higher performance

Switch-mode topologies have come to dominate today's power conversion scene, offering higher efficiency, lower heat dissipation and smaller circuit size than traditional linear regulators. These advantages are compelling for all but a few applications.

Designers are trying to get efficiencies above 90% while miniaturizing power supplies, and there is still room for improvement. However, the limited FOM (numerical merit) of traditional silicon power MOSFETs and IGBTs is slowing progress. Moreover, dealing with switching noise becomes even more challenging as higher switching frequencies are employed to reduce the size of filtering components.

Luckily, there is a solution. Wide bandgap power semiconductors are now delivering on the promises they made during their development. Silicon carbide (SiC) devices in particular are becoming commercially competitive. In particular, improved conversion efficiency can reduce the total number of power switches, reducing reliance on heatsinks and thus offsetting overall BOM cost.

The overall cost-effectiveness allows designers to reap the benefits of wide bandgap semiconductors, including much-needed efficiency gains, smaller circuit sizes, and overcoming switching noise challenges. I was.

SiC power transistors have the advantages of low RDS(ON) relative to die size, industry standard package size, and high voltage, as well as being able to handle large currents and improve breakdown safety. , with no tail current, resulting in significantly cleaner and faster switching. By enabling higher switching frequencies, smaller filter components, and lower electrical noise, SiC breaks traditional silicon trade-offs and gives power supply designers a 'new way of doing things'.

Illustration

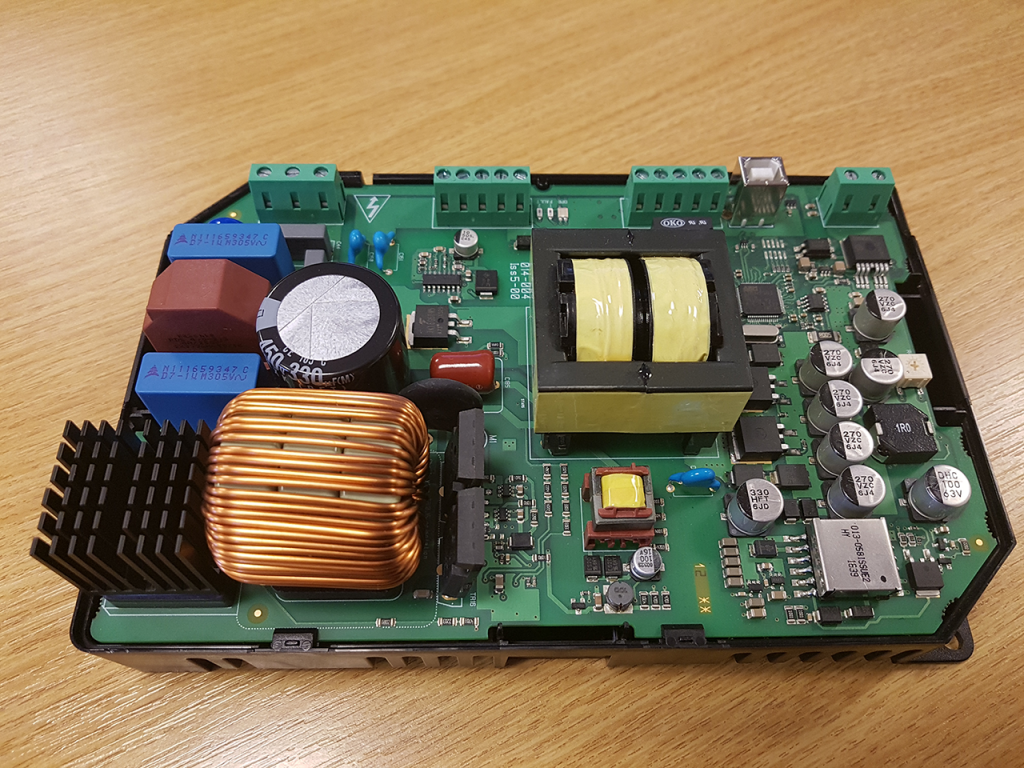

Deep Sea Electronics (DSE) used Qorvo's SiC power transistors to achieve extremely high efficiency in the latest generation of backup battery chargers (Figure 1). These advanced components also help streamline design and facilitate compliance with EMC regulations.

DSE is a UK based technology company with roots in commercial diving technology and a 40 year history in advanced power management. Our chargers are deployed where performance, quality and complete reliability are prerequisites. For example, it is deployed in equipment such as fire safety and security systems, generator management, marine power, transportation and emergency vehicles.

DSE serves customers worldwide, so the charger's input is a universal AC input boosted to 400V DC by an internal switched mode power supply (SMPS). In this 450W charger, by setting the SMPS switching frequency to a high 70kHz, we were able to reduce the size of the external components while improving efficiency compared to conventional products. Conventional silicon MOSFETs can handle this frequency, but they generate a large amount of switching noise, so further noise reduction is required to comply with EMC regulations. Also, the first MOSFETs tested by DSE engineers required large snubber circuits and large heat sinks, increasing both size and BOM cost.

To improve on the 94% efficiency demonstrated in these first silicon-based prototypes and address the challenges of noise, size, and BOM cost, the team replaced the MOSFETs with Qorvo's SiC cascodes.

A SiC cascode combines a SiC high voltage JFET as the primary current carrying device with a low voltage conventional MOSFET that keeps the SiC device off when the control signal is low and turns it on when the control goes high. . In this way, power supply designers can benefit from the inherently higher efficiency of normally-on SiC JFETs while using conventional MOSFET gate control voltages and driver circuits.

Excellent SiC switching characteristics (fast and low noise) improve efficiency up to 96%, eliminate the need for heatsinks and simplify EMC measures. It also reduced the size and cost of passive components and the cost of the PCB. So what is the key to improving performance simply by changing from silicon to SiC? One of the most influential parameters is Coss, the output capacitance of the device. A cascode's Coss is much lower than a comparable MOSFET, allowing the output to change quickly in response to the gate signal. In fact, DSE engineers had to use gate resistors to slow the switching signal so that the MOSFET's output could catch up. In contrast, SiC devices could be driven at high speed without any problems.

In addition, Coss, combined with the on-resistance, RDS(ON), defines the key FOM for power switches. The UCC0650K SiC cascodes employed in DSE's chargers have a typical RDS(ON) in the 34-45mΩ range, while comparable silicon MOSFETs have an RDS(ON) of around 80mΩ. In addition, the temperature coefficient of RDS(ON) is much more stable for SiC devices, and this time UJC0650K showed about 30% better stability than the MOSFET evaluated by DSE. It is also more stable than comparable Gallium Nitride (GaN) devices, and unlike GaN alternatives, SiC cascodes are readily available, more competitively priced, and available in industry-standard power packages. .

DSE's next-generation high-efficiency, low-noise battery charger is now in production. The design team is currently looking into designing with a modern surface mount version of Qorvo's SiC cascode for all new DSE battery chargers in the future.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.