Evolution of SiC semiconductors

The goal of the new generation of semiconductor switch technology is “faster” and SiC semiconductors are no exception. Next-generation wide-bandgap technology promises further improvements in efficiency, size, and cost in many application areas.

"Generation" has many meanings throughout history. In 1965, rock band The Who spoke "about my generation" and stunned the band's founding with radical music and outrageous behavior. But technology wasn't changing at the same rate. The transistor was invented a generation ago, in 1945, but it took another five years for pocket calculators and another 15 years for Motorola to sell its first "cell phone."

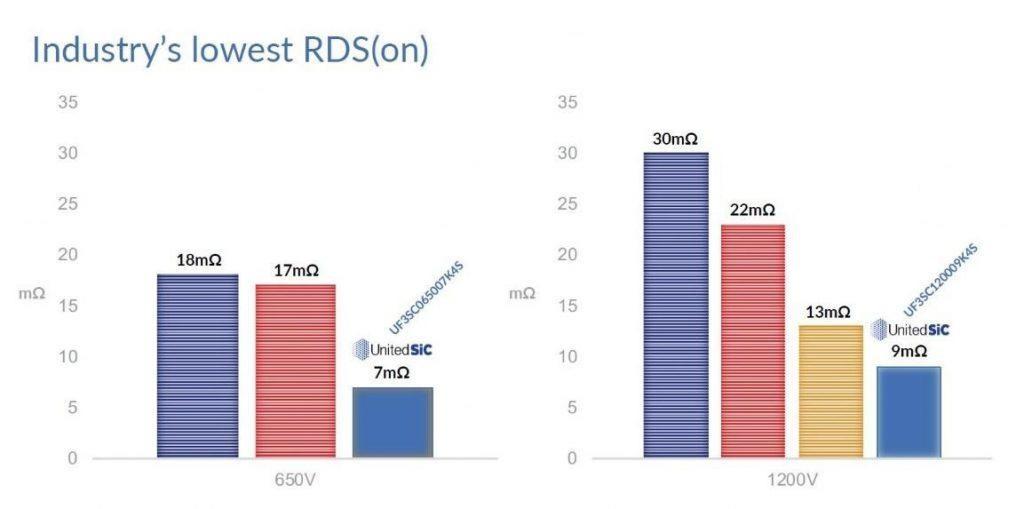

Today, technology “generations” are changing rapidly. 5G is already a reality and 6G is already in development. This was over two years ago. As for semiconductor power switches, the development of wide bandgap devices centered on SiC and GaN is progressing in the same way. SiC has made the leap from its commercial beginnings six years ago to today's 3rd generation and is expected to be priced on par with Si switches, especially when considering the knock-on benefits. For example, modern cascode ultra-fast normally-off SiC-FETs are as easy to drive and use as IGBTs and Si-MOSFETs, but dramatically faster and have much higher static and dynamic losses. lower. Qorvo's devices feature class-leading on-resistance of less than 9mΩ for 1200V devices and less than 7mΩ for 650V versions, and new packages such as DFN8x8 have been introduced to take advantage of SiC performance with low internal inductance and thermal resistance.

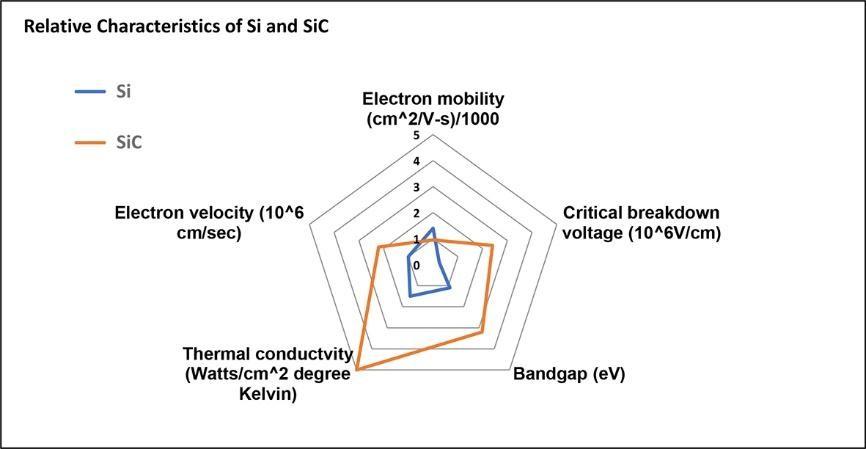

The advantage of SiC was evident from the beginning, as it had a wider bandgap, which improved breakdown voltage and temperature rating. Even better is the "Rds.A" figure, which is 2.5 times better than Si-MOSFETs in the same voltage class and 13 times better than IGBTs. The rate is ten times that of silicon.

This will lead to low-loss performance in space-constrained and energy-conscious fields such as 5G and data centers, and improved efficiency of traction inverters in electric vehicles will reduce the size and cost of heat sinks, thereby reducing heat sink size and cost. A wide range of applications are opening up for SiC semiconductors, such as improving the cruising range of automobiles. However, SiC-FETs also have properties that make them ideal for other applications, such as solid-state circuit breakers for domestic and commercial use, circuit protection, and even linear operation. The target fields range from aerospace, IT, industrial, household, renewable energy, etc. to fields that need to be efficient without cooling and reduce cost, size and environmental impact. Masu.

But SiC semiconductors are still at the beginning of the evolution curve, how far can it go? Systems engineers eagerly await investigation, but we can make some predictions. This is based on the fact that the evolution of SiC semiconductors to date is similar to the evolution of Si devices in the past.

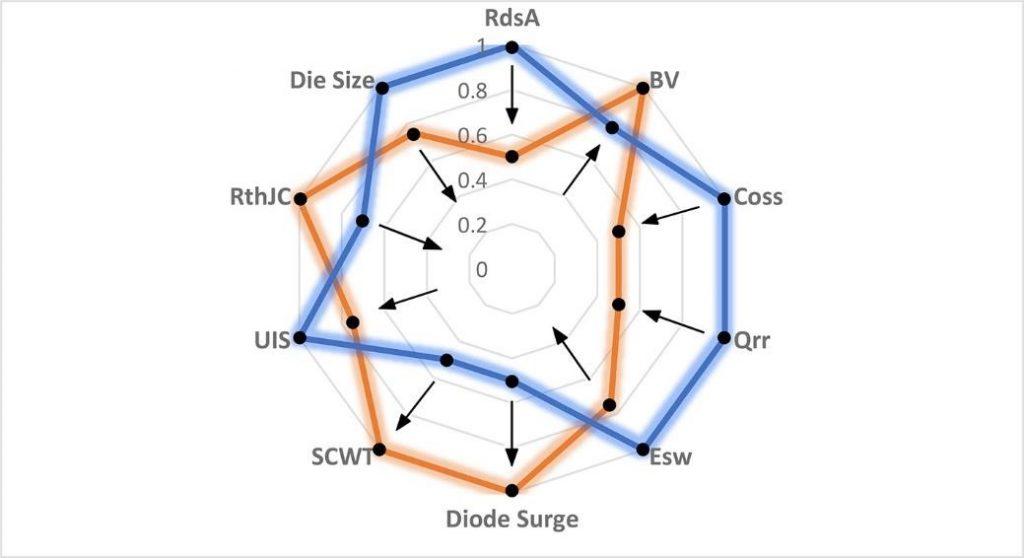

The cell design is a further improvement and refinement of Rds. A figure of merit, which means a smaller die, faster switching, and lower on-resistance, reduces the device capacitance as the die size decreases. This means less energy is lost during switching and less gate drive losses. Rated voltages increase to 1700V and above, increasing the use of "stacked cascodes" that can be rated at several kV. Leadless devices become popular as current ratings increase and the limits of traditional bond-lead packages are reached.

And leadless packages allow higher switching frequencies. However, the TO-247 3-lead and 4-lead packages are still available as drop-in replacements for legacy designs of IGBTs and Si-MOSFETs. As the technology matures, reliability is increasingly proven, yields improve, and costs can be expected to decrease as die sizes shrink.

As SiC semiconductor technology advances, challenges lie ahead. For example, wafers must be thicker to accommodate higher processing temperatures, which increases cost. However, Qorvo has a roadmap and is also releasing its fourth generation of SiC-FET devices.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.