"Go boldly" - switch to the future

In modern car cockpits, mechanical switches and actuators are becoming a thing of the past. Under the hood, mechanical switches and the isolation of high current and voltage connections are also being replaced by modern SiC semiconductors.

Engineers aren't known for taking particularly bold actions, but it's their job to be cautious and question their work. We all trust our cars to be safe and reliable, and we believe change is evolutionary rather than revolutionary. But EVs are forcing a shift in approach to design, more like a mobile computing platform than a modern automobile is about transportation from point A to point B.

Despite the high-tech innovation of EVs, there are still some parts that rely on simple machines. Wheel bearings aren't going away any time soon, but electromechanical devices like contactors and circuit breakers are still commonplace to cut off high voltage/high current battery connections to ensure safety and prevent failures. Used when With potential currents of thousands of amps, battery voltages up to 800V, and inherent shock and vibration, the equipment must be very robust. There is concern that the case may explode when overloaded. This is because the drawn arc burns the contact material and generates heat, along with the wear that occurs during dielectric breakdown.

Arcs can also be quenched with slightly exotic techniques such as using expensive gas-filled housings, blowing with compressed air, or directing a longer path with a magnetic field. All of these suffer from slow response times, which means that applications are looking for better solutions.

SiC semiconductors are now a viable alternative.

Solid-state circuit breakers have been around for a long time, but implementations using GTOs, IGBTs, and more recently MOSFETs have been less than ideal. Modern 650V devices have on-resistances below 7mΩ and 1200V types below 9mΩ, with far less problems with conduction losses and the high junction temperature ratings inherent in SiC semiconductors also help. Offered in a TO-247 package and with easy gate drive, SiC FETs can often replace IGBTs and MOSFETs in existing breaker designs with up to 1000 times faster operating times than mechanical ones. It achieves low loss and, of course, no arcing. It is also a robust device with an overvoltage avalanche energy rating.

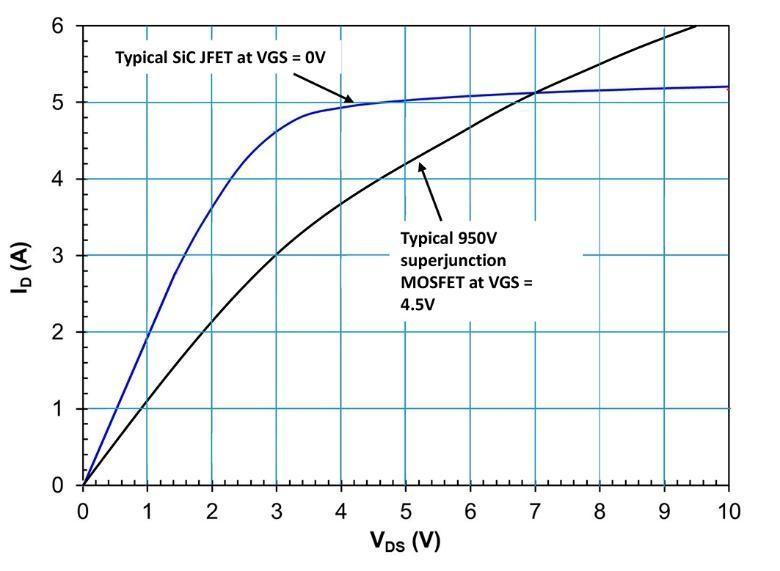

When breakers and contactors become solid state, other control possibilities open up. Conduction can be actively controlled to limit inrush current, "pre-charge" or handle short circuits more intelligently. For example, JFETs in SiC FETs have an inherent "pinch-off" effect that allows setting the saturation current. This current is fairly constant with applied voltage and decreases with temperature, resulting in a mild power-limiting action (Figure 1).

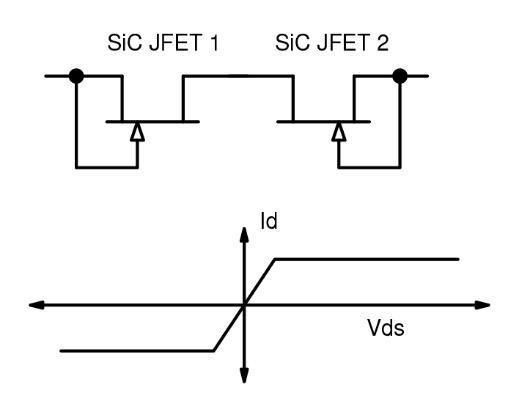

This characteristic means that a very simple current limiter can be implemented with just two SiC JFETs chosen for suitable saturation current (Figure 2).

Qorvo's normally-on SiC JFETs configured as circuit breakers can also be configured as true two-terminal circuit breaker modules without the need for an external auxiliary power supply or internal DC/DC converter.

Lucky charms like bold things

Engineers have always known that “if it moves, it will break,” and the latest EV cockpits with touchscreen controls and drive-by-wire accommodate this. The latest SiC FET and JFET devices should make mechanical contactors and circuit breakers historic and encourage designers to take bold challenges.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.