The Real Meaning of SiC in Electric Vehicle Related Applications

A combination of various attributes has established silicon carbide (SiC) as the premier semiconductor technology for the electric vehicle (EV) sector. The device is superior to conventional silicon (Si) based devices. Its benefits include high voltage ratings, excellent power conversion efficiency levels, and the ability to handle high temperatures.

On-board chargers (OBCs), DC-DC converters, and traction inverters all benefit from SiC, and ongoing process and architectural enhancements have already added considerable appeal. Such enhancements extend the range of operating parameters for this wide-bandgap material, further reducing the power losses experienced. At the same time, higher production volumes enable it means it could reach a more attractive price point.

The significance of using SiC in electric vehicles

Very briefly, here are some of the impact SiC is currently having on the electric vehicle industry: Each should be carefully considered.

1. The Need for Faster Charging Cycles

Due to the need for faster charging cycles, electric vehicle engineering teams are looking into introducing OBCs that can operate at higher voltages. Then SiC devices were introduced that can handle these voltages. Commonly available 650V voltage rated devices are not always sufficient, and higher voltage rated semiconductors are needed to accommodate higher battery voltages. At the same time, it would be difficult to justify the increased cost associated with using 900V or 1200V rated devices. A solution that can withstand the voltage rise and doesn't drive up the associated costs too much is best in this regard.

2. Need to support higher operating frequencies

To switch faster, switching losses must be minimized. Otherwise, the efficiency level will decrease and more space will be required for the heat dissipation mechanism (which will increase the overall size, weight and cost, so increasing the heat dissipation mechanism should be avoided. ).

3. Significant reduction in operating losses

This increases the distance an electric vehicle can travel before it needs to be recharged. It is equally effective for the miniaturization of electric vehicle batteries. Both are interesting prospects for automakers.

4. Cost Considerations

Another key factor accelerating the transition from internal combustion engine vehicles to EVs is the ability of manufacturers to reduce the money consumers have to pay to purchase these vehicles. In order to keep costs down, the costs associated with various components must be kept down (the inverter section is a particularly large portion of the total cost).

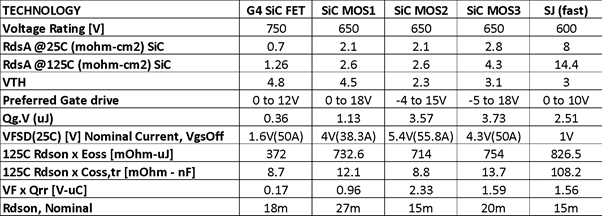

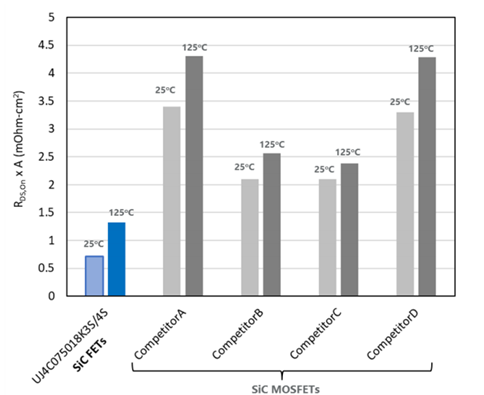

Recognizing these qualities and the urgency to find viable solutions is crucial. Qorvo's fourth generation (Gen4) SiC technology is the perfect device for these issues. Table 1 shows a comparison of specifications made against SiC technologies from other vendors. Here we compare a 750V rated UJ4C075018K4S SiC FET with three 650V SiCMOSFETs and a Si-based superjunction FET device. Although the voltage rating of Gen4 SiC FETs is significantly higher, the on-resistance per unit area of this technology is two to three times better than other SiC MOSFETs and more than an order of magnitude better than Si FETs. This means you can achieve comparable performance in a much smaller package.

The reason for the very low on-resistance per unit area is the high density trench SiC JFET structure incorporated in the SiCFET. It is packaged with a low voltage Si MOSFET. The reduced area of SiC JFETs means that they exhibit much lower on-resistance for a given chip size (Figure 1). Conversely, smaller FETs with lower capacitance can be used while maintaining acceptable on-resistance.

In order to reduce the electrical and thermal resistance values (and the associated losses), SiC wafers are considerably thinner. The wafer is attached to a copper (Cu) lead frame via a silver (Ag) sintering material (six times the thermal conductivity of standard soldering material).

Other benefits offered by Qorvo's Gen4 SiC technology include a dramatic reduction in associated gate drive losses when compared to other devices. Therefore, the gate drive IC can prevent overheating. Also, no negative gate drive is required. Excellent VF.QRR figure of merit (FoM) is exhibited thanks to low forward voltage drop (VFSD) and minimal reverse recovery charge (QRR). This is by far the best performance among devices on the market today.

SiC is already making EV drivetrains and battery systems more efficient, and can achieve performance benchmarks well beyond the range of Si semiconductor technology. With the advent of next-generation SiC technology, its value will be further recognized in relation to the widespread adoption of EVs around the world in the coming years.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.