Overview

In the previous article, I explained the advantages of using SiC in more detail, but in this article, I will explain the reliability of WBG semiconductors.

Please refer to the previous article from the link below.

SiC FET with proven reliability

Although there are currently concerns about reliability, some WBG devices are quite effective. For example, SiC MOSFETs and GaN devices are very sensitive to gate voltages whose absolute maximum values are very close to their recommended operating conditions. SiC FETs, on the other hand, are tolerant of a wide range of gate voltages with wide margins to the absolute maximum, and parts are available with gate-clamp diodes that provide another level of protection against overvoltage and ESD. Short-circuit rating is probably a major concern in EV motor drives as IGBTs have become the benchmark for robustness.

The GaN devices are certainly underperforming in this respect, but the SiC FETs score again. SiC JFETs are known to be excellent in short circuit handling, and SiC JFETs in cascode SiC FETs control the peak current, so unlike SiC MOSFETs and IGBTs, short circuit characteristics that do not depend on gate drive voltage can be obtained. .

Also, SiC JFETs have higher peak temperatures, which allows for longer short-circuit times. Automotive applications are expected to withstand a 5µs short circuit before the protection mechanism activates. Tests using Qorvo's 650V SiC FETs show that they can withstand a 400V DC bus for at least 8µs after 100 short-circuit events with no degradation of on-resistance or gate threshold at elevated temperatures. (Fig. 3). Other tests using 1200 V devices at 850 VDS (Fig. 4) show that the peak short-circuit current decreases with initial junction temperature and the total energy dissipated decreases, indicating a positive impact on the on-resistance of SiC FETs. A benign effect on the temperature coefficient of was demonstrated. This effect has also been confirmed to result in uniform short-circuit current flow across multiple cells within a die.

SiC JFETs can be designed for good trade-offs in automotive applications between the interdependent parameters of short-circuit current, on-resistance, and turn-on speed. Another stress that can occur is a voltage spike that exceeds the maximum drain-source rating. Again GaN is not immune, but SiC FETs have very good avalanche ratings. The internal JFET gate-drain junction breaks over, allowing current to flow through RG in Figure 1 (SIC FET 2 for EV applications) until the SiC JFET gate-source voltage exceeds a threshold voltage of approximately -6 V. rise.

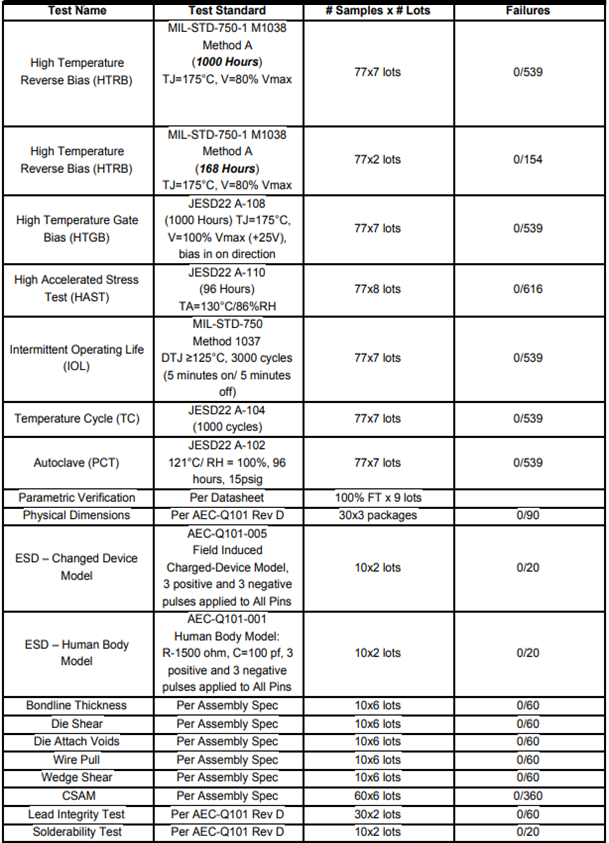

This turns on the channel and clamps the overvoltage. Low-voltage Si-MOSFETs also avalanche, but Qorvo cathodes incorporate avalanche clamp diodes in all cells and have a low breakdown voltage, so the energy dissipated in the Si-MOSFETs mostly causes a temperature rise. not. Testing by Qorvo shows no failure of SiC FET components after 1000 hours of avalanche at 150°C in production testing at 100% avalanche capability as a backstop. All devices designed for automotive applications must have the relevant approvals of AECQ-101 for semiconductors. The tests performed for approval are listed in Table 2, along with the results for Qorvo SiC FETs in the TO-220-3L, TO-247-3L, and their “Kelvin-connected” TO-247-4L packages. Masu.

Briefly, no device failures or significant changes in performance occurred with the stated sample sizes. According to JEDEC standard JESD 85, it has a FIT rate (failures per billion hours) greater than 1.117 and an MTTF greater than 102,132 years assuming a temperature of 55°C and 60% reliability. equivalent to This is inherently superior to Si due to SiC's wider bandgap, which also provides a robustness advantage.

compelling case

The latest AEC-Q qualified wide bandgap devices, like Qorvo's SiC FETs, are true contenders for the next generation of EV motor drives, offering superior performance, overall cost savings, and a competitive advantage in such a challenging environment. Meets the demand for proven robust operation in As a result, SiC is expected to dominate drivetrains in the next decade.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.