NVIDIA AOI Summit Nagoya was held on June 20, 2019 (Thursday), hosted by NVIDIA G.K. (hereinafter referred to as NVIDIA). In this report article, we will introduce the event and the products exhibited at the demo booth.

What is AOI?

AOIとは、Automated Optical Inspectionの略で、「自動外観検査」や「自動光学検査装置」、またはそれに関連する技術のことです。

ディープラーニングの技術革新を背景に、製造業の外観検査にディープラーニングを活用する事例が広がっています。

例えば、従来人間の感覚を用いて製品の品質を判定する官能試験は、ディープラーニングを活用し高精度かつ短時間で実現することが可能になりました。ディープラーニングによる外観検査は、少子高齢化による労働力不足問題を解決するうえでも、製造業に大きな変化をもたらすテクノロジーです。

Sessions by leading AI partners

NVIDIA introduced overseas examples of AOI and the latest GPU technology that supports AOI, and industry-leading partners introduced software and hardware solutions for AOI as well as consultation services. I was.

| Lecture title | Lecture company name |

|---|---|

| Opening remarks | Nvidia G.K. |

| AI Industrial Inspection and Predictive Maintenance | NVIDIA Corporation |

| AI Utilization Strategy in Industry | connectome.design Inc. |

| 文系出身営業担当がモデル開発?ReNomTAG/IMGの活用 〜誰でも簡単に短時間でAI開発できる時代へ〜 |

GRID Co., Ltd. |

| AI anomaly judgment and classification by 3D detection system | Crystal Method Co., Ltd. |

| Introduction of AI visual inspection Box Neural Cube | Musashi Seimitsu Industry Co., Ltd. |

| Introduction of AI solution examples (failure prediction and image judgment service) | YE DIGITAL Co., Ltd. |

| Automation of visual inspection that continues until actual operation -The end of tests that rely on humans- |

Macnica |

| closing remarks | Macnica CLAVIS Company |

The sessions include the contents of each phase, such as the research stage, PoC, and mass production.

Interesting survey results

I'm curious about the specific situations in which deep learning visual inspection is being introduced or considered in the manufacturing industry. We will introduce the voices of the participants based on the results of the questionnaire conducted after the session.

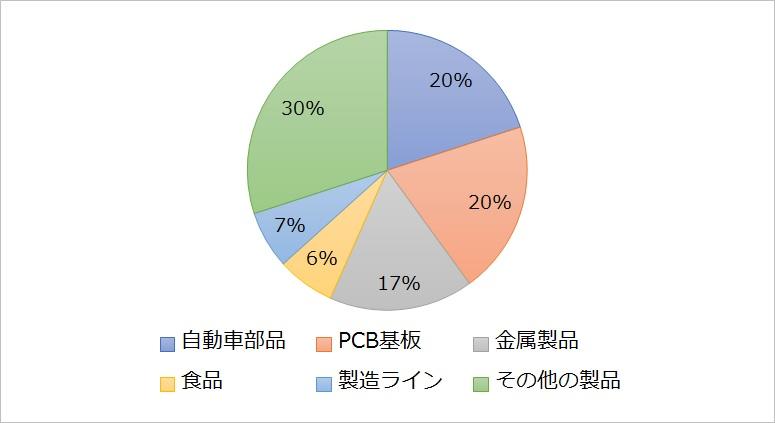

Q. What is the target of the deep learning visual inspection currently being introduced or considered?

Since this year's event was held in Nagoya, automobile parts were the most common, followed by PCB substrates and metal products. Regarding the responses to "other products," although it was a minority opinion, it was found that there are various fields, and the needs for deep learning visual inspection are required in a wide range of industries.

Q. What is the biggest issue in promoting the introduction and consideration of deep learning visual inspection?

|

introduction |

Data collection |

study |

|---|---|---|

|

Inadequate learning environment |

data is not collected |

long learning time |

|

Data collection man-hours |

||

|

Inability to build an in-house training system |

Inspection accuracy (overdetection, oversight) |

Reliability of training data |

|

It is difficult to determine the definition of defects due to the large number of product types to be inspected. |

In terms of introduction and consideration, there were many issues related to data collection, and there were also opinions unique to the manufacturing industry, such as the difficulty in determining defect definitions due to the large number of product types to be inspected. However, looking at this result, it can be seen that at the stage of recognizing it as your own problem and looking for a solution to it, you are making more concrete studies toward actual operation.

The heat is amazing! demonstration booth

It was a great success, with many participants enthusiastically exchanging information with the speakers and presenters. Since there are fewer events held in the Tokai region compared to the Kanto region, the participants took advantage of this opportunity to discuss more specific ways to introduce deep learning visual inspection to their workplaces. rice field.

Here, we would like to introduce the products that were exhibited at the partner's demo booth.

① Experience high-speed inference "HFBX-6300_DL"

HFBX-6300_DL is an industrial development kit that enables deep learning at the edge. You can easily evaluate the deep learning framework "KAIBER" developed especially for embedded systems. By adopting KAIBER, it is possible to build a deep learning system without using a network or cloud, and you can experience high-speed inference on the Intel platform from learning with this single development kit.

(2) Neural Cube, a quick introduction of AI to the workplace

Neural Cubeは、NVIDIA Jetson TX2を内蔵したAIユニットで、画像判定・音声認識・データ分析/予測など、求められるさまざまなタスクに合わせて、イメージしている形のAIを簡単に実装させることができます。

Jetpack・Deep Learning関連ソフト・外部デバイスSDKをセットアップ済みのため、従来必要なセットアップ時間を短縮します。またソフト開発は統一言語のPythonでプログラム可能で、使いやすさを追求したインターフェースポートを搭載しており、実装までの手間を大幅に軽減します。

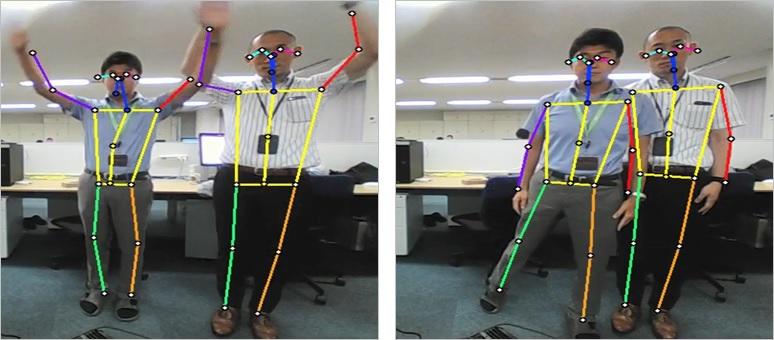

③ Skeleton detection "Vision Pose" with only a web camera

VisionPoseは、Kinectや他の深度(depth)センサー付きカメラに頼らず、 ディープラーニング(深層学習)を使用し、WEBカメラのみで人間の骨格や深度情報を検出することが可能なAI(人工知能)システムです。

写真はマクニカで動作させてみた時の映像を切り出したものです。人が重なっても後ろの人の骨格が正確に検知されているのが分かります。

Next time will be held in Osaka!

いかがでしたでしょうか。本レポートではNVIDIA AOI Summit Nagoyaのセッションやデモブースの様子についてご紹介しました。参加できなかった方や、イベント終了後にNVIDIA AOI Summit Nagoyaを知った方には当日の様子をイメージしていただけたかなと思います。

そして、次回は大阪にてAIの最新動向や事例をご紹介するイベントを予定しております。

関東のイベントにはなかなか参加できないという方は、ぜひこの機会にご参加ください。

当日の展示製品や、ソリューション、その他のご質問はこちらの問い合わせフォームをご利用ください。