Issues of Wired/Wireless Communication at Manufacturing Sites

In recent years, the use of Ethernet for industrial equipment has increased rapidly due to the increase in communication traffic associated with the spread of AI and IoT. The advantages of using Ethernet are the stability of high-speed, large-capacity communication and the ability to connect to various devices with a single cable.

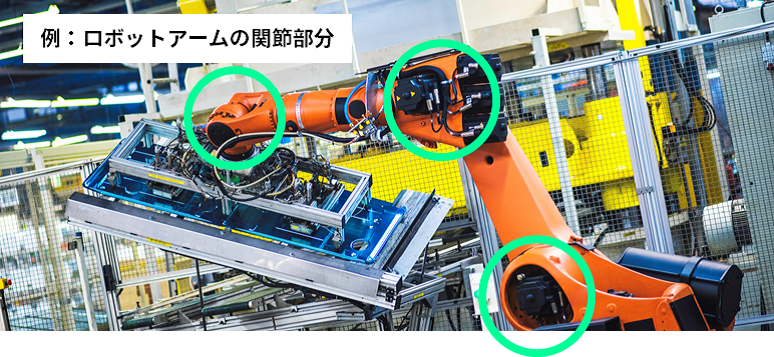

While wired Ethernet can provide reliable communication, it is safe to use, but in some areas of the factory network it is difficult to install a wired LAN. In addition, industrial equipment with a wide range of motion, such as articulated robots and surveillance cameras that rotate 360°, has some issues and restrictions.

For example, even if a flexible cable is used, it is necessary to consider the routing that can withstand advanced robot movements, and the size of the RJ45 connector commonly used in Ethernet is large, making it difficult to miniaturize the board. is mentioned.

Therefore, when considering wired Ethernet to be wireless, WiFi and 920MHz band short-range wireless are selected. However, due to the frequent movement of goods and people in the factory, there are places where it is difficult for radio waves to reach. In addition, some equipment may generate noise, making it susceptible to communication interference.

In other words, wireless that “uses radio waves” itself becomes a risk.

As a solution to solve these problems, we propose an Ethernet-compatible contactless communication module kit that allowsonly the necessary parts to be "contactless without using radio waves" while maintaining the Ethernet communication of the factory infrastructure.

We will introduce the benefits of using this product and what use cases it is suitable for.

What is an Ethernet compatible non-contact communication module kit?

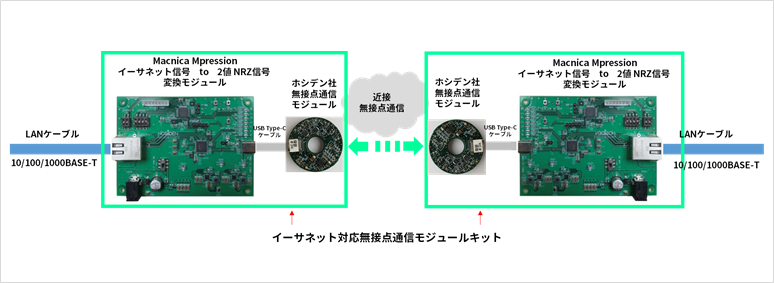

Hosiden Corporation and our company Mpression (*) have jointly developed an Ethernet signal to binary NRZ signal conversion module using a Marvell Ethernet IC.

This kit, which combines a jointly developed module and a contactless communication module from Hosiden Corporation, enables contactless Ethernet communication at 10/100/1000BASE-T speeds without the need for cables.

*The distance at which non-contact communication is possible is about 5mm.

Advantages of using this module kit

・Stable Ethernet communication can be achieved with devices that are difficult to miniaturize or wire.

・Because it does not use radio waves, it is less susceptible to noise interference

・リファレンスデザインがあるので、開発工数を削減可能

Use cases for Ethernet-compatible contactless communication

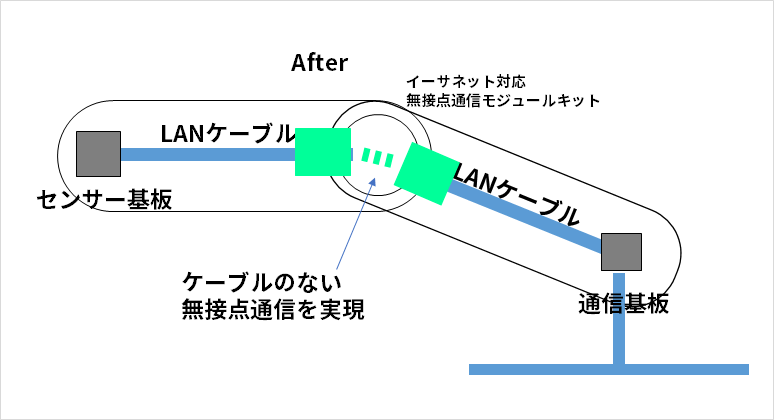

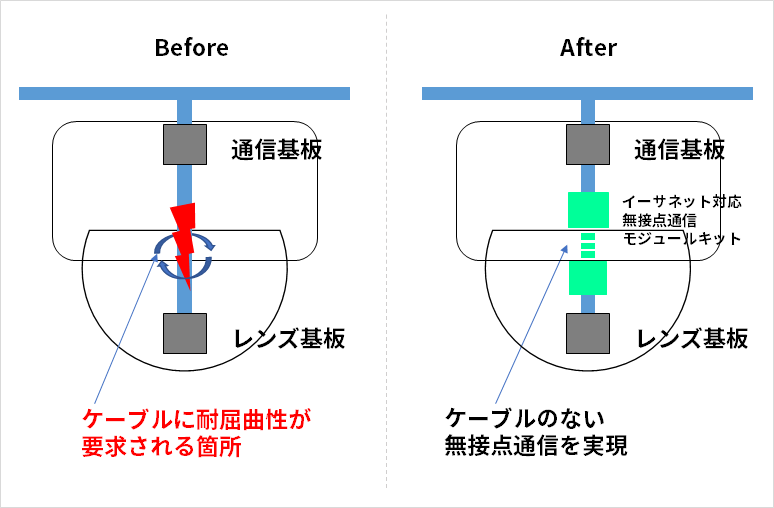

The communication cables for the joints of robot arms and the communication cables for the lens substrate and body of 360-degree omnidirectional surveillance cameras have so far been designed using flexible cables. By making this part non-contact, it becomes possible to realize a free structure that can handle infinite rotation without cables.

Use case 1

Use case 2

"Macnica 's technological capabilities" solve problems

In order to realize contactless Ethernet communication, we received a request from Hosiden Corporation to develop new Ethernet technology. A conversion board was required to connect Hosiden Corporation's contactless communication module and Ethernet.

We have jointly developed an Ethernet signal to binary NRZ signal conversion module using the Marvell Ethernet Switch/PHY IC, which has a long track record in the market, by applying the know-how of our company Mpression's various technologies.

This can be provided by Hosiden as a set with Hosiden's contactless communication module, and it is also possible to use it as a reference design for your design.

Macnica Mpression Board Specifications

・Auto-Negotiation compatible (ON/OFF switchable)

・Supported speed can be changed with Dip switch (10/100/1000Mbps)

・Display communication status with LED

・Confirmed connection performance with Hosiden's new technology contactless Ethernet module

・Evernet IC from MARVELL company, whose track record has been confirmed

88E6341 (Ethernet L2 Switch IC)

Main features of MARVELL Ethernet IC 88E6341

・ Built-in 4Port PHY

・MAC I/F ~2.5Gbps

・Compatible with packets up to the L3 layer (96 bytes from the beginning) by TCAM

(Example) User-specific packet processing (QoS, etc.)

・Built-in Z80 MCU

Please contact us if you are interested.

How was the introduction of how to realize contactless Ethernet communication in industrial equipment? The Ethernet compatible non-contact communication module kit introduced this time can be customized according to the customer's set specifications at the time of mass production, such as module size and non-contact communication distance. Ethernet signal to binary NRZ signal conversion module and non-contact communication module integration is also possible.

If you are interested in Hosiden's proximity contactless module or our Ethernet technology development, please feel free to contact us.

Macnica, Ltd.'s original technology brand, Mpression, develops products and services that support customers in solving design and development issues and accelerating innovation, with a focus on semiconductors and networks.

If you are interested in what kind of consultation you can do, please take a look at this.

If you are interested in Hosiden-sama's module, please take a look here.