Flexible printed circuit (FPC) made by inkjet printing

Flexible printed circuits (FPC) are thin, flexible, and bendable, so they are widely used in connection cables that connect thin devices and moving parts. However, although FPCs appear to be widely used at first glance, their applications have been extremely limited due to the problem of high development and procurement costs.

In order to solve this problem, Elephantech has commercialized P-Flex® (product name) for the first time in the world as a next-generation flexible substrate manufactured using inkjet printing technology.

What is P-Flex®? We will also briefly introduce the features.

New technology, Pure Additive® method

P-Flex® is a flexible printed wiring board manufactured by inkjet printing and electroless copper plating. Unlike the production of flexible printed wiring boards by photolithography, which applies conventional photographic technology, this method does not require molds and requires fewer processes and fewer raw materials.

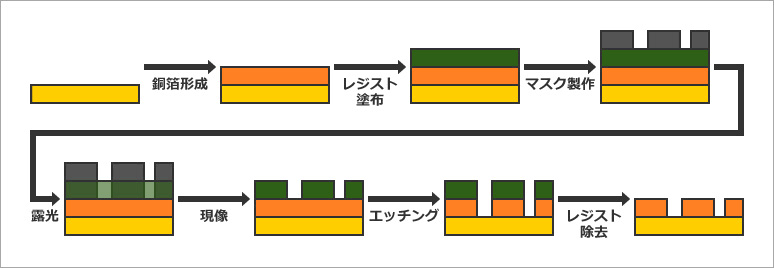

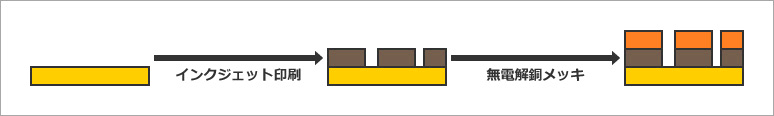

The diagram below shows the work process of the conventional substrate manufacturing method (subtractive method) and the substrate manufacturing method used in P-Flex® (PureAdditive® method).

Conventional substrate manufacturing method (subtractive method)

New Technology Substrate Manufacturing Method (Pure Additive® Method)

The features of this new manufacturing method named the Pure Additive® method are:

- No mold is required because no exposure mask is used.

- Since raw materials such as copper are added only where necessary, there is little waste of materials and less liquid waste.

That's the point. For this reason, it is possible to provide it at a low price even though it is a flexible printed circuit board (FPC).

Short manufacturing lead time

Reduce manufacturing time

P-Flex® has a short manufacturing process and does not require the manufacture of molds, which significantly reduces manufacturing time.

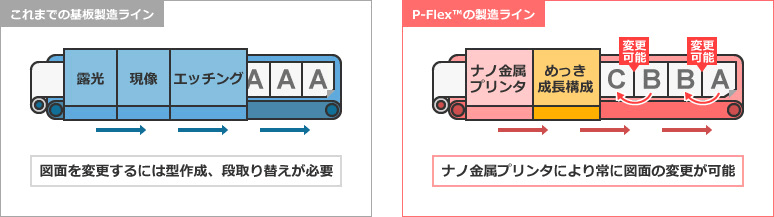

The table below shows the existing PFC process and the P-Flex® manufacturing process.

There is no need to create photomasks, block copies, or molds, and each task becomes simple.

| Manufacturing process | Existing FPC process | P-Flex® process |

| circuit pattern formation | Etching, photomask making | Inkjet printing + electroless copper plating |

| symbol printing | Block copy creation | UV inkjet printing |

| solder resist | Block copy creation | UV inkjet printing |

| Outline cut | Punch, mold making | Laser cut |

| Making reinforcing plate | Punch, mold making | Laser cut |

Drawings can be changed at any time

Another benefit related to time reduction is design change. With the P-Flex® process, which does not require mold making or setup, it is possible to commercialize design changes in a short time after production has started.

- Drawings can be changed anytime and as many times as you like, even after production has started.

- Even if parts are discontinued, the production drawing can be changed non-stop.

- Feel free to try out new ICs and designs to improve performance and reduce costs

- Even substrates that are made infrequently can be manufactured immediately without the need to store molds.

- Harness/board integrated design can reduce the number of parts

Versatile

Do you think flexible printed circuit boards (FPC) are only used as harnesses to connect rigid printed circuit boards?

Depending on your ideas, it can be used for various purposes, such as mounting parts such as LEDs, electrostatic touch, electrodes for living bodies, electrochemical sensors, wireless antennas, etc.

If you are interested, please feel free to contact us.

How was the flexible printed circuit (FPC) manufactured by printing technology?

With the new technology, the barriers to the introduction of flexible printed circuit boards (FPC), such as costs and delivery times, have been lowered, and the range of applications has probably expanded.

If you are interested, please feel free to contact us.

We will hold an Elephantech seminar at your company!

Elephantech product seminars can be held at your company.

The time is 1 to 2 hours and can be customized according to your desired content.

If you would like to hold a product seminar, please indicate that you would like to hold a seminar from the inquiry column.