An example of manufacturing consulting that supports "creating added value with a commitment to design"

"Switch development that is not bound by fixed concepts" (lighting switch design)

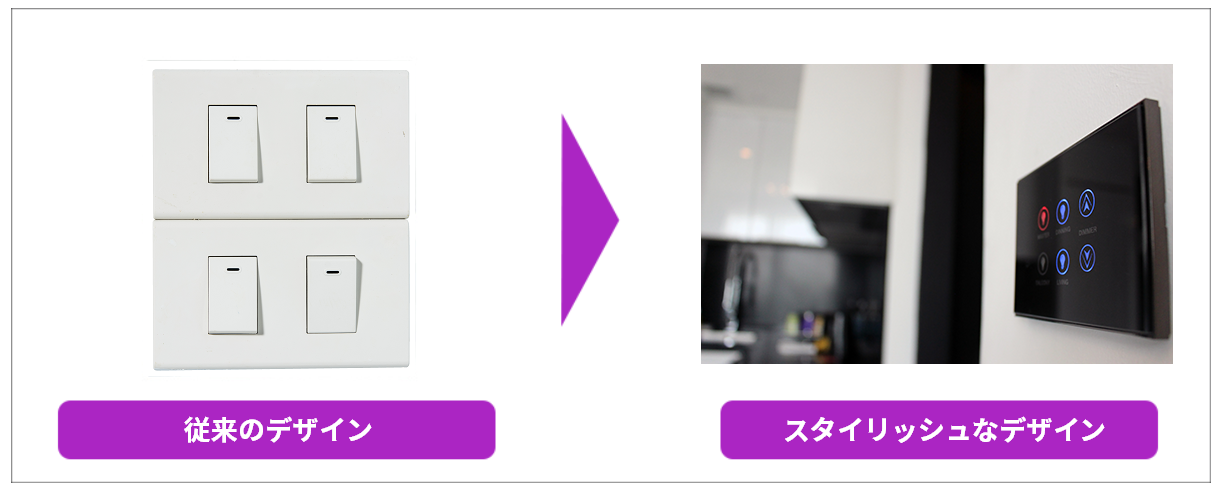

Lighting switches are indispensable in buildings, houses, facilities, etc. Conventionally, the size and materials are almost fixed, and the design is limited. Have you ever thought, "If only I could make something stylish..."?

By paying attention to the details, you can differentiate yourself from others through the added value of the user's taste and convenience, and ultimately improve the asset value of buildings, residences, facilities, etc. We will briefly introduce the process from consultation to consulting proposal for a company that wants to make a switch using ○○ (a different material than conventional materials).

Macnica 's "manufacturing consulting" has provided consulting services to many companies by listening to customers' questions about what they want to achieve, such as "If we use technology, can we do XX beyond the conventional framework?" I've been working on it.

"Specifications for requested functions (PCB design + method using electrical technology to mass production consultation example": Company B

| ■ Contents of consultation |

| ・I want to make touch panel type glass switches for residential lighting. |

|

■ Problems of Company B |

| ・I don't have the know-how for circuit design, where can I get support? ・What are the specifications of the substrate to be attached to the glass and how should it be placed to work? |

Flow up to this proposal

|

1. inquiry |

I want to make touch panel type glass switches for residential lighting. |

|

2. hearing |

Hearing about the details of what the customer wants to do and the specifications expected |

|

3. investigation, consideration |

Assuming a "touch panel type switch with high design made of glass" in a house, we examined the optimum method. 1. A capacitive touch sensor is used in consideration of cases in which users operate the device with wet hands, such as after taking a bath or returning home on a rainy day. 2. The specifications for flexible substrates were formulated to save space. In addition, by developing several patterns of microcomputer software, it is designed to be reusable by simply switching the software. 3. In order to keep maintenance costs down, we have devised ways to prevent breakdowns while emphasizing design. Mechanism design that prevents dust and water droplets from entering gaps. Four. Connect switches and lights wirelessly to eliminate the need for wires behind the wall. |

|

4. Verification of implementation method |

Verification of the realization of a glass material touch panel switch using a prototype (PoC) |

|

5. Suggestion |

Customer's idea (glass material switch) |

|

*What is Technical Conformity? |

|

Points of this concert

- Reduction of parts cost (Even if the product pattern is different, it can be realized by standardizing parts by devising the design)

- Common software

- Utilization of housing designers who have worked on products of major manufacturers

- Implementation of verification in anticipation of product realization by prototype (PoC)

I want to keep this in mind when selecting a contractor for electronic device development! three points

When we outsource the design of a product to the IoT, we may encounter unexpected problems depending on the technical capabilities of the subcontractor, and development may take time.

We have seen many cases of customers failing due to mistakes in the selection of contractors as a result of commercializing IoT devices and other products through outsourced development. Here are three things to keep in mind to avoid such risks.

1. Having the know-how to develop the latest technology

2. Ensure the quality standards required for the equipment

3. Ability to procure parts during mass production

If you are interested in the details, please refer to here.

Related article

Manufacturing consulting service

Manufacturing consulting service Please refer to the button below for details.

please consult

Macnica provides consulting regarding the development and mass production of electronic devices in all fields.

Please feel free to contact us.