NVIDIA AOI Summit Nagoya was held on June 20, 2019 (Thursday), hosted by NVIDIA G.K. (hereinafter referred to as NVIDIA). In this report article, we will introduce the event and the products exhibited at the demo booth.

What is AOI?

AOI is an abbreviation for Automated Optical Inspection, and refers to "automatic visual inspection", "automatic optical inspection equipment", or related technologies.

Against the background of technological innovation in deep learning, cases of using deep learning for visual inspection in the manufacturing industry are spreading.

For example, sensory tests that use human senses to determine product quality can now be performed with high accuracy and in a short time using deep learning. Appearance inspection using deep learning is a technology that will bring about major changes in the manufacturing industry in terms of solving the labor shortage problem caused by the declining birthrate and aging population.

Sessions by leading AI partners

NVIDIA introduced overseas examples of AOI and the latest GPU technology that supports AOI, and industry-leading partners introduced software and hardware solutions for AOI as well as consultation services. I was.

| Lecture title | Lecture company name |

|---|---|

|

Opening remarks

|

Nvidia G.K.

|

|

AI Industrial Inspection and Predictive Maintenance

|

NVIDIA Corporation

|

|

AI Utilization Strategy in Industry

|

connectome.design Inc.

|

|

Model development by a salesperson with a liberal arts background? Utilization of ReNomTAG/IMG

?To an era where anyone can easily develop AI in a short time? |

GRID Co., Ltd.

|

|

AI anomaly judgment and classification by 3D detection system

|

Crystal Method Co., Ltd.

|

|

Introduction of AI visual inspection Box Neural Cube

|

Musashi Seimitsu Industry Co., Ltd.

|

|

Introduction of AI solution examples (failure prediction and image judgment service)

|

YE DIGITAL Co., Ltd.

|

|

Automation of visual inspection that continues until actual operation

-The end of tests that rely on humans- |

Macnica

|

|

closing remarks

|

Macnica CLAVIS Company

|

The sessions include the contents of each phase, such as the research stage, PoC, and mass production.

Interesting survey results

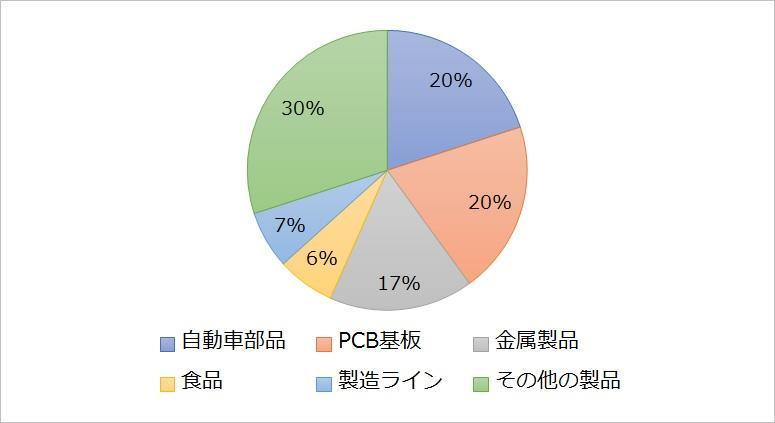

I'm curious about the specific situations in which deep learning visual inspection is being introduced or considered in the manufacturing industry. We will introduce the voices of the participants based on the results of the questionnaire conducted after the session.

Q. What is the target of the deep learning visual inspection currently being introduced or considered?

Since this year's event was held in Nagoya, automobile parts were the most common, followed by PCB substrates and metal products. Regarding the responses to "other products," although it was a minority opinion, it was found that there are various fields, and the needs for deep learning visual inspection are required in a wide range of industries.

Q. What is the biggest issue in promoting the introduction and consideration of deep learning visual inspection?

|

introduction |

Data collection |

study |

|---|---|---|

|

Inadequate learning environment |

data is not collected |

long learning time |

|

Data collection man-hours |

||

|

Inability to build an in-house training system |

Inspection accuracy (overdetection, oversight) |

Reliability of training data |

|

It is difficult to determine the definition of defects due to the large number of product types to be inspected. |

In terms of introduction and consideration, there were many issues related to data collection, and there were also opinions unique to the manufacturing industry, such as the difficulty in determining defect definitions due to the large number of product types to be inspected. However, looking at this result, it can be seen that at the stage of recognizing it as your own problem and looking for a solution to it, you are making more concrete studies toward actual operation.

The heat is amazing! demonstration booth

It was a great success, with many participants enthusiastically exchanging information with the speakers and presenters. Since there are fewer events held in the Tokai region compared to the Kanto region, the participants took advantage of this opportunity to discuss more specific ways to introduce deep learning visual inspection to their workplaces. rice field.

Here, we would like to introduce the products that were exhibited at the partner's demo booth.

① Experience high-speed inference "HFBX-6300_DL"

HFBX-6300_DL is an industrial development kit that enables deep learning at the edge. You can easily evaluate the deep learning framework "KAIBER" developed especially for embedded systems. By adopting KAIBER, it is possible to build a deep learning system without using a network or cloud, and you can experience high-speed inference on the Intel platform from learning with this single development kit.

(2) Neural Cube, a quick introduction of AI to the workplace

Neural Cube is an AI unit with built-in NVIDIA Jetson TX2, and it can easily implement AI in the form you imagine according to various tasks required such as image judgment, voice recognition, data analysis/prediction. increase.

Jetpack, Deep Learning related software, and external device SDK are already set up, shortening the setup time required in the past. In addition, software development can be programmed in Python, a unified language, and an interface port that pursues ease of use is installed, greatly reducing the time required for implementation.

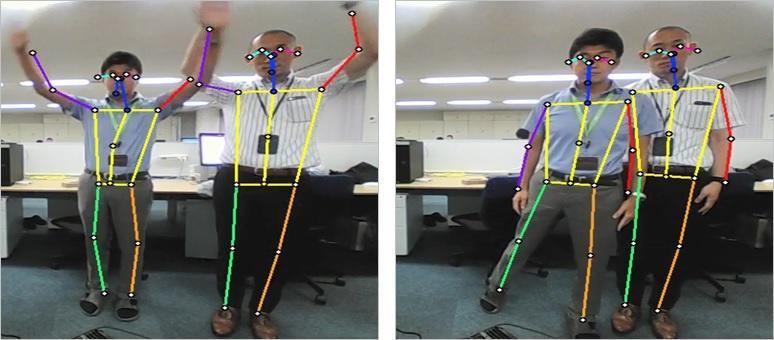

③ Skeleton detection "Vision Pose" with only a web camera

VisionPose is an AI (artificial intelligence) that uses deep learning to detect human skeleton and depth information using only web cameras, without relying on Kinect or other cameras with depth sensors. system.

The photo is an excerpt from footage taken when running the system on Macnica. You can see that even when two people overlap, the skeleton of the person behind is accurately detected.

Next time will be held in Osaka!

What did you think. This report introduced the session and demo booth at NVIDIA AOI Summit Nagoya. I hope that those who were unable to participate, or those who learned about NVIDIA AOI Summit Nagoya after the event, were able to imagine what the day would be like.

Next time, we are planning an event in Osaka to introduce the latest trends and examples of AI.

If you can't participate in events in Kanto, please join us at this opportunity.

Please use this inquiry form for the products exhibited on the day, solutions, and other questions.