毎年20万台以上生産されている製品があります。なんだと思いますか?

それは、「産業用ロボット」です。産業用ロボットというと、アーム型のものや自動搬送機などが思い浮かぶのではないでしょうか?

総出荷台数(台): 233,386(日本ロボット工業会 統計データ)

今回は、このような産業用ロボットに搭載されるセンサをご紹介します。

産業用ロボットとは

産業用ロボットは、ISOによると「3軸以上の自由度を持つ、自動制御、プログラム可能なマニピュレータ」と定義されています。(Wikipedia)

産業用ロボットは、単独で動く製品もありますが、ティーチングマシンと使うことが多いでしょう。

ティーチングマシンは、ロボットに動作を覚えさせる装置です。一番イメージしやすいのは、車などの工場で塗装するロボットなんかはイメージつきますか?

これまでは、職人が行なっていた作業を、職人自らがティーチングマシンを使ってロボットに動作を覚えさせます。録音するようなイメージですね。ロボットは、教えられた動きを再生するように同じ動きをし、職人技を再現します。

このように、産業用ロボットは生産現場で休むことなく働いてくれます。

データ出力タイプによるセンサの分類

さて、そんな産業用ロボットには、様々なセンサが搭載されています。センサといっても様々ですが、センサ製品は主に3つのデータ出力タイプに分類されます。

- センサの出力を内部のアンプでコンディショニングしたアナログ信号を出力するタイプ

- センサの出力を内部のADCを使用して、ディジタルデータに変換されて、SPIやI2Cなどのマイコンとの接続を簡単にしたデジタル出力タイプ

- 物体検出センサなど、デバイス内部で複雑で規模が大きいデータを最適な信号出力に変換し出力するタイプ

どれもメリット・デメリットがあるので、最適な出力を選択してセンサのデータを活用することが大切です。

産業用ロボットを設計する上で重要なポイント

産業用ロボットを設計する上で、重要なポイントは、温度やノイズ特性です。

特にアナログ信号で出力されるタイプは、センサからの出力からAD変換までの入力までの経路で、

- いかにノイズを抑えられるか?

- 温度の要因を排除できるか?

が設計上の重要なポイントになります。

加えて、実装時のリフローやエージングによるわずかな歪みやたわみなどが生じることで、ソフトウェアで補正する必要も出てきます。

データシート上だけではわからないセンサの奥深さを事前に調査することも、設計の近道。「急がば回れ」ですよ。

産業用ロボットに必要なセンサ

センサは、実に様々な種類があり、どれを選んだらいいのか分からないことがありませんか?

まずは、産業用ロボットに使うセンサを「必須センサ」「便利センサ」「今後必要センサ」の3つに分けてご紹介します。

必須センサ

どのような産業用ロボットにも必ず必要なセンサがあります。もしかしたら、当たり前すぎて、センサと思っていないかもしれません。「電圧」「電流」「温度」「加速度」です。それぞれ説明します。

電圧センサ

「電圧」については、レギュレータで供給している機械や、ACそのままなんてものもあると思いますが、機械を動かすために電圧は欠かせません。レギュレータも1つのセンサと考えていいでしょう。

電圧の変動は、故障や不具合の原因にいたる大きな要因です。安定した電圧を供給することは当たり前すぎて、センサとの認識は薄いかもしれませんが、「電圧が低下したらアラームを出す」仕組みはすでにセンサとしての役割を果たしています。

電流センサ

「電流」は、回路が壊れると過電流が流れたり、想定電流以下になることがあります。

特に産業用ロボットは、ノイズ環境が悪いところで作業をする事が多く、ノイズによる故障はなるべく避けたいところ。

そんな時、電流センサを使用すると、正常稼働時と故障時の回路に流れる電流が変化をするので、異常を素早く検出できます。電源近辺だけでなく、モータやアクチュエータなどの駆動電流回路にも搭載しておくと、異常検知が可能です。

温度センサ

「温度」は、機械や周辺の温度を測定します。

モータやアクチュエータなど常に稼働している部品は、熱が伴います。産業用ロボットの機器内の場合、モータの異常発熱やロボットの制御を統括するCPUの温度測定などで使用します。機械を長く使うためには、発熱量を監視する事は非常に重要です。

温度センサは奥が深く、センサ部分の素材によって、温度の変化する抵抗値をADCでセンシングするのが一般的な温度センサです。

最近は、MEMS 技術の向上により、デバイス内部の温度センサを使用した温度センシングも多くなりました。外部にセンサ素材が不要な分、計測可能な温度は限定されてしまうことも多くありますが、一般的な用途を想定する分には、不自由さはあまりないと言える精度まで向上してきました。

また、機械以外の周囲温度を測定することも必要かもしれません。建機などは、室外で作業をする事が多く、外気温が低すぎると機械が効率よく動かせないとか、そういった環境温度を測る事は、今後の製品開発にも役立てます。

加速度センサ

「加速度」センサは、ゲーム機などに搭載されてからその知名度は爆発的に伸びました。

最近では、ちょっとした評価ボードにも搭載されるようになり、容易に入手できるようになりました。水晶による発振タイプから、MEMSによる製品まで様々な種類の加速度センサがあります。MEMSタイプは、安価で入手でき、様々な用途に搭載されるようになりました。

使用方法は、オフセットされた位置から、どのくらいの傾きが発生したのかを計測するためのセンサです。産業用ロボットには、欠かせない重要なセンサになっています。位置情報や、機械の異常時に発生する微弱な振動を検出することも可能です。異常振動を信号解析することで、予知保全につながります。

加速度センサも種類が多く、デバイスの選定には、温度特性やノイズ性能はもちろんのこと、精度や消費電力、応答性能も重要です。産業用ロボットの種類によっては、アナログ出力の加速度センサを選定するのもひとつの選択肢になります。

便利センサ

最近のセンサは、形状、コスト、性能のバリエーションが大変豊富になりました。必ずしも必須ではないものの、搭載しておくとIoTのセンサデータとして活用可能なセンサをご紹介します。

「動きや位置」を知るセンサ

産業用ロボットの動力は、サーボモータであったり、DCモータであったり、アクチュエーターなどが担当します。しかし、ただ回ればいいというものは少なく、どの程度動いたか監視する必要があります。

自動搬送機などは、指定した通りに動いたかどうかを知る必要もあるでしょう。アーム型ロボットのサーボモータが何回転しているのか知る必要があります。さらには、「X方向に27.23度、Y方向に31.85度」などのきめ細かい角度指定があるかもしれません。

そんな時に必要なセンサは、加速度センサやジャイロセンサなどが有効です。ここでは、動きや位置を知るセンサが必須になりますので、ご紹介します。

ジャイロセンサ

ジャイロセンサは、回転角の角速度から現在の速度を算出することができ、速度と時間から、移動した距離を算出できます。

GPS信号を用いて距離も算出できますが、GPSが届かない室内においては、加速度センサとジャイロセンサを用いて、GPSの代用となります。これも、精度が悪いと、位置がずれるということも発生します。

GPSの代用で検討する場合は、IMU(慣性ユニット)を選択すると、面倒な調整が不要で、出荷時に校正済み製品も多くラインアップされています。

「指定した位置を知る」センサ

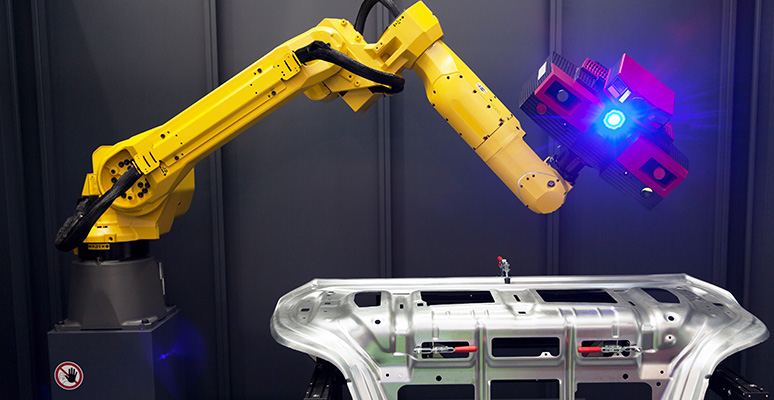

指定した位置を知るセンサとして、最近注目されているのが、「ToF(Time of Flight)」と呼ばれるセンサです。

ToF センサ

ToF センサは、光の反射で高さや距離を認識するセンサです。

従来までは、超音波センサや圧力センサや気圧センサを使って実装していたのですが、光の発光から反射して受光するまでの時間を計測する仕組みです。

光を反射する物体には依存しないので、奥行きや距離などを正確に測定できるタイプのセンサとして注目を集めており、これからの位置センサとして活用範囲が期待されているセンサです。

「画像で判断」イメージセンサ

イメージセンサも種類が豊富にありますが、画素数はひとつの選択肢となります。

画角が大きければ、きれない映像データとなりますがその分、画像処理にはCPUパワーを要します。画素数が小さければ、比較的軽いCPUパワーで処理することも可能です。

また、イメージセンサのダイナミックレンジも重要です。ダイナミックレンジが狭いと、対象物と背景などの差やちょっとした欠けなどの検出に支障をきたすことが考えられます。ダイナミックレンジが広いと、明瞭な画像となり、その後の処理を簡素化できる可能性が高いです。

「外部環境」センサ

外部の環境は、多くの活用方法があります。代表的な温度センサはもちろんですが、産業用ロボットが作業する内容によって異なります。

- 圧力センサ

- ひずみゲージ(重量センサ)

- 照度センサ

- ガスセンサ

- 赤外線センサ

- 高温用温度センサ

これらのセンサは、産業用ロボットの使用環境によって異なりますが、用途によっては、高精度なセンサを選択する必要があります。

今後必要センサ

ここでは、今後期待されるセンサをご紹介します。

今は、まだ予算的にもスペックオーバであったり、そこまで不要という機能も、実際に使用するユーザにとっては便利になるかもしれないこともあります。そんなセンサを2つほど、ご紹介します。

ジェスチャーセンサ

ジェスチャーセンサは、光学センサのひとつで、近距離で使用するセンサです。仕組みとしては、遮られた光の反射から距離や位置を割り出すことが可能です。

応用例としては、機器に直接触れることができない工場や衛生管理が厳しい環境での使用が想定されます。

音声認識センサ

音声による操作は、まだまだこれらかの技術かもしれませんが、音声系システムは、制御するCPUが安価になってくれば、新しい操作系として十分活用が見込めます。

そういう意味で、声のセンサとして、音声認識はこれから期待されている分野と言えます。

まとめ

さて、産業用ロボットに必要センサを紹介してみましたが、いかがでしょうか?

センサは、価格や種類も多く、選択するのが難しい電子デバイスのひとつです。

簡単に扱えそうでも、期待した精度が出ないということもよく聞く話です。

まずは、評価ボード等を入手して、自分が期待した値や精度が確保できるのか、温度特性やノイズ性能など、ハード・ソフトを含めてしっかり検証することが大切です。

評価ボードも、単体のセンサから、複数のセンサが搭載されているものもあります。マクニカ オンラインサービスから、最適な評価ボードを探してみてください。

おすすめ記事/資料はこちら

モータ制御で考慮すべき3つの視点 [出張版 APS実験室]

IoT機器の通信はどれを選べばいいか?[出張版 APS実験室]

IoT 機器向けのセンサを種類別に紹介

| APS実験室 [室長] 浦邉 康雄 |

1995年 半導体商社で自社製品の開発に従事

2001年 SMSC(現Microchip)にて、Ethernet製品のFAEとして幅広い業務に従事

2010年 Altera(現Intel)に入社し、FPGAのFAEに従事

2011年 組み込み系RTOS(eForce)にて、営業技術としてOSの販売やコンサルなどを行う

2015年から現在のAPS実験室室長を務める。

ハード・ソフト・デジタル・アナログ・通信・電源など多岐にわたるコンテンツをエンジニア目線でわかりやすく提供しています。

著書

CQ出版でEthernet関係を中心に、MbedやCortex-Mコアに関する記事を寄稿