はじめに

高電圧スイッチングアプリケーションにおいて、シリコンMOSFETやIGBTがSiC MOSFETへ置き換えられる動きが増えてきています。

しかし、SiC MOSFETにはゲートドライブに関する固有の要件があり、最適なゲートドライバー製品を選定しないとSiC MOSFETの持つ特性を十分に活かすことができません。

この記事では、SiC MOSFETの特性について概要を紹介し、最適なゲートドライブ設計に関係する重要な設計要件について解説します。

なお、シリコンMOSFETの特性とSiC MOSFETの特性を比較するために、次の2つの製品の特性を比較して解説します。

・シリコンMOSFET: NTH4L040N65S3F

(onsemi社 スーパージャンクションMOSFET SUPERFET® III, FRFET®, 650 V, 65 A, 40 mΩ, TO-247-4L)

・SiC MOSFET: NTH4L045N065SC1

(onsemi社 SiC MOSFET, 650 V, 55 A, 33 mΩ, TO-247-4L)

シリコンMOSFETとSiC MOSFETの特性比較

トランスコンダクタンス (gFS)

トランスコンダクタンスはMOSFETのゲート電圧変化(VGS-VTH)に対するドレイン電流(ID)変化の比率で、MOSFETの入力に対する出力のゲインを定義しています。

ID=gFS×(VGS-VTH)

SiC MOSFETのトランスコンダクタンスはシリコンMOSFETのそれに比べて低い特性値になっています。

・シリコンMOSFET

・SiC MOSFET

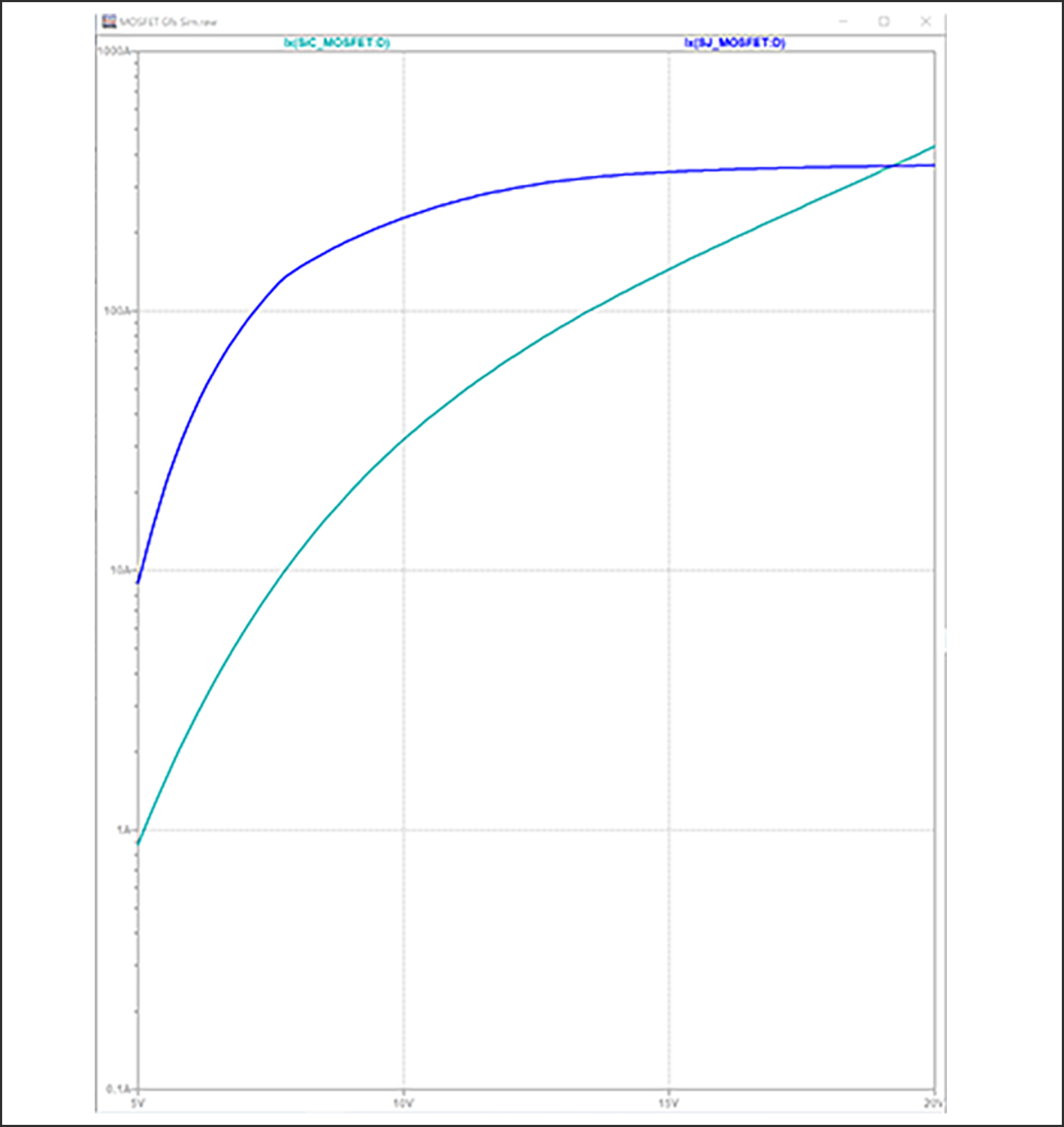

Analog Devices社LTspice®を使って、今回比較で使用しているシリコンMOSFETとSiC MOSFETのgFSをシミュレーションしました。

(青:シリコンMOSFET、緑:SiC MOSFET)

この結果からシリコンMOSFETは高いgFSにより急峻なIDの立ち上がりが確認できますが、特定のVGS以上では電流が飽和しています。

しかし、SiC MOSFETは低いgFSによりIDの立ち上がりはなだらかですが、電流が飽和しないためVGSを高くするほどSiC MOSFETの低オン抵抗の恩恵を得られることが分かります。

横軸がVGS、縦軸がIDを示しています。ドレイン電圧(VDS)は400Vとしています。

オン抵抗 (RDS(on))

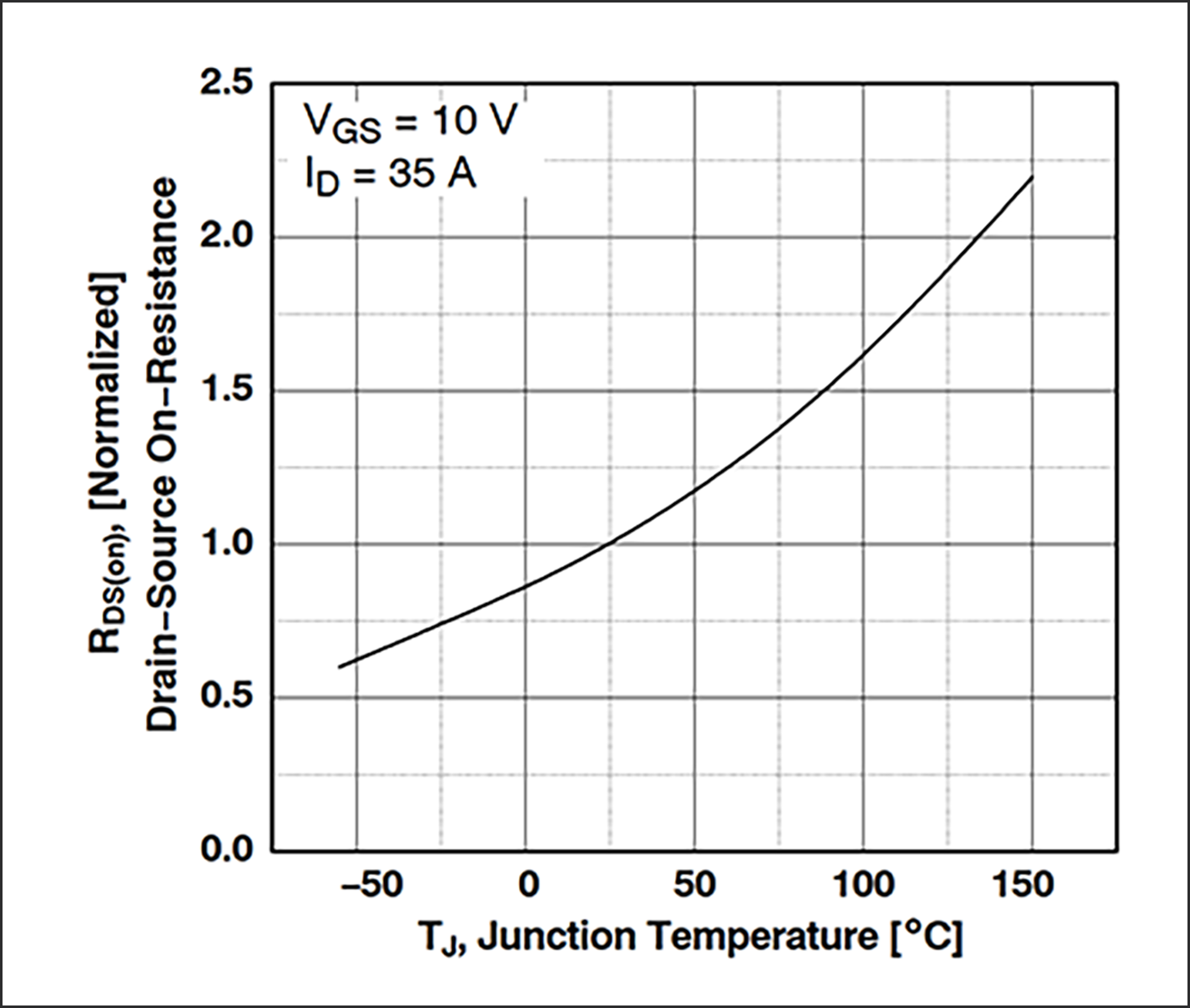

シリコンMOSFETのオン抵抗はVGS>VTHの時は常に正の温度係数を持っていますが、

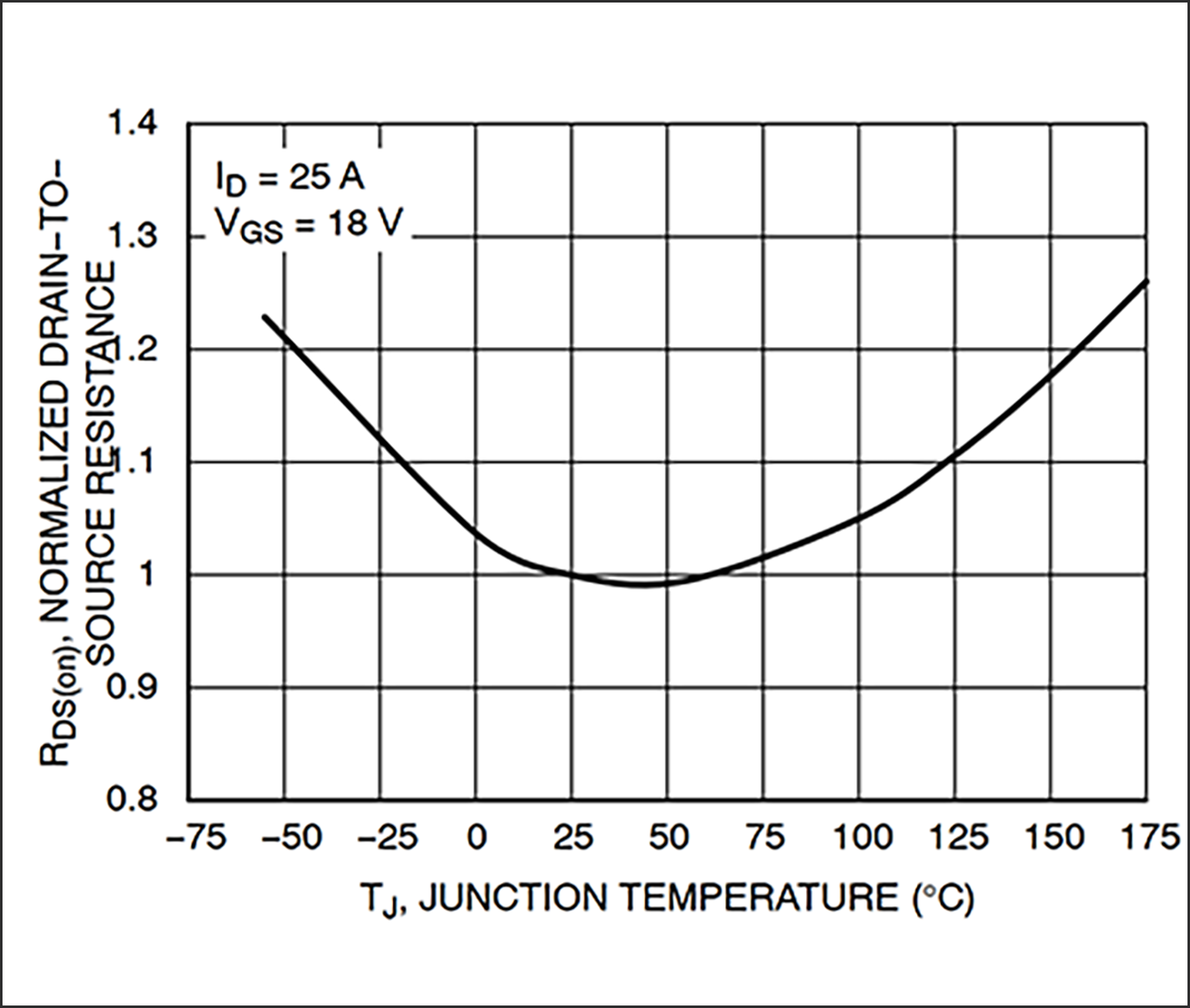

SiC MOSFETはVGSが低いときには負の温度係数を持つチャネル抵抗(RCH)が支配的になり、VGSが高いときには正の温度係数をもつJFET抵抗(RJ)、ドリフト領域抵抗(RDRIFT)が支配的になります。

この2つの温度係数を持つ抵抗成分の影響で、SiC MOSFETのジャンクション温度とオン抵抗の関係は、図に示すような放物線の特性となります。

(左:シリコンMOSFET、右:SiC MOSFET)

オン抵抗の温度特性をシミュレーションした結果からも

SiC MOSFETのVGSを上げれば、この負の温度係数の影響を受けずに、正の温度係数をもった特性になることが分かります。

(緑:VGS=15V / ピンク:VGS=18V / 黒:VGS=20V)

横軸:ジャンクション温度 ※グラフの単位[V]は[℃]に置き換えます。

縦軸:オン抵抗

ID=100Aです。

入力容量 (CISS)

SiC MOSFETのダイはシリコンMOSFETのダイに比べてはるかに小さいです。

これによりSiC MOSFETの入力容量CISSはシリコンMOSFETのそれよりも小さくなり、それによってゲート電荷QGもSiC MOSFETの方がシリコンMOSFETよりも小さくなります。

・シリコンMOSFET

・SiC MOSFET

ゲートドライブ電流を制限するために、外付けに高いシリーズゲート抵抗を配置し増減することで、ゲート信号の時定数を調整することができ、VDSのdV/dtの遷移をより高い自由度で制御できます。

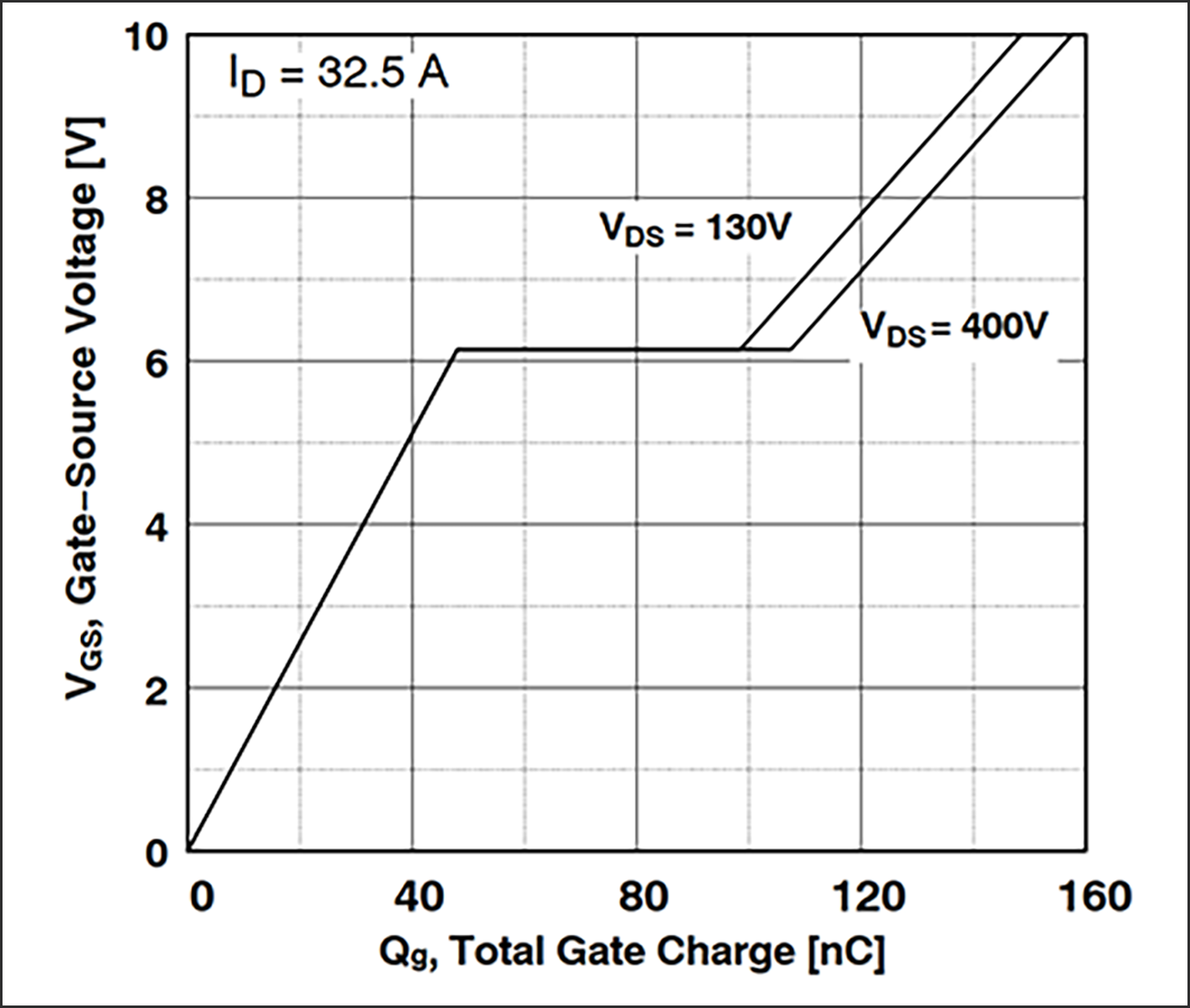

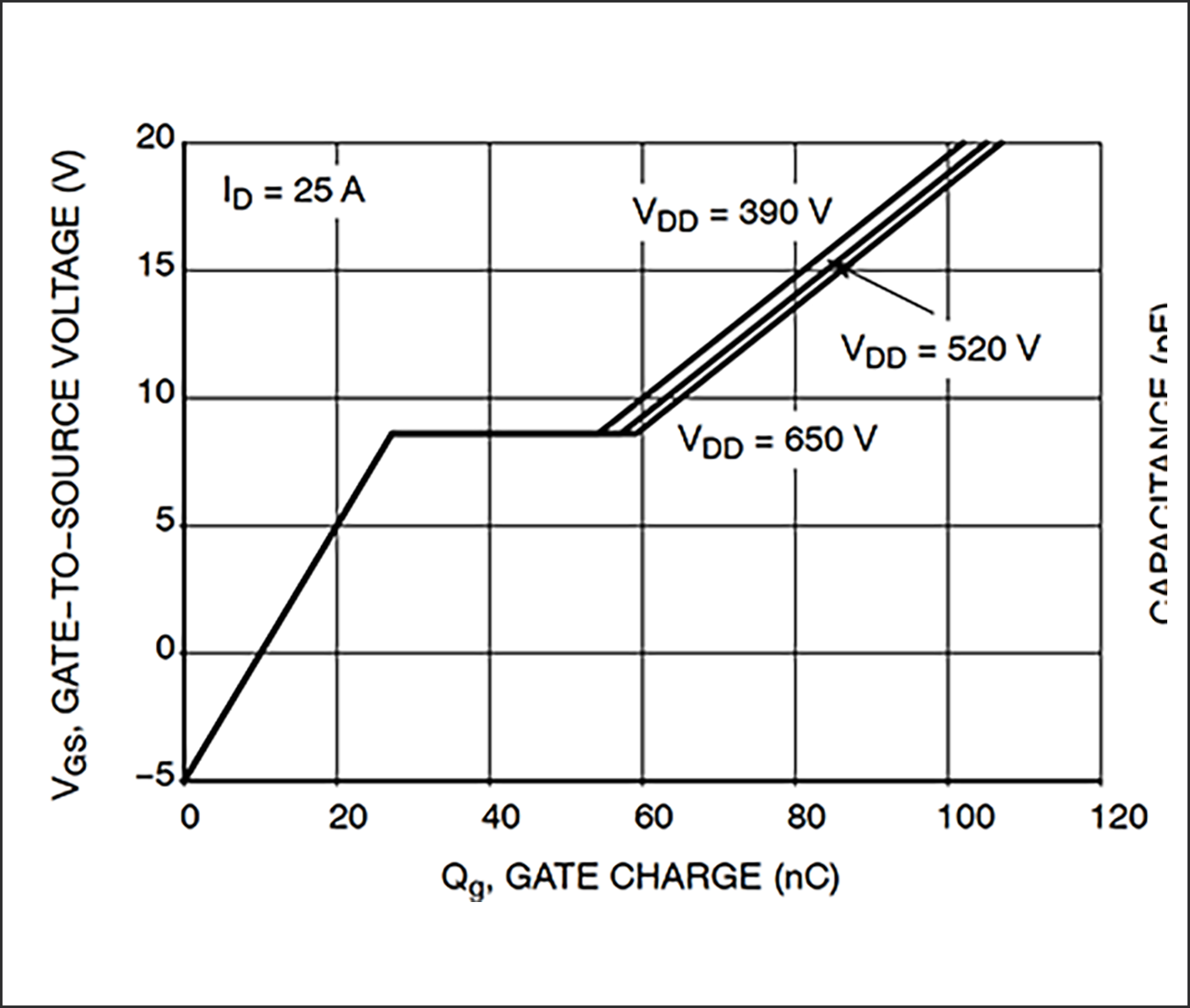

ゲート電荷 QG

うえの”入力容量 (CISS)”で説明した通り、SiC MOSFETのゲート電荷QGはシリコンMOSFETよりも小さくなります。

しかし、VGS対ゲート電荷(QG)曲線ではシリコンMOSFETはVGS=0Vから曲線が開始しているのに対し、SiC MOSFETではVGS=-5Vから曲線が開始しています。

これはSiC MOSFETのゲートをフル放電するためにはVGSを-5Vまでプルダウンしなければならないことを意味します。

(左:シリコンMOSFET、右:SiC MOSFET)

また、SiC MOSFETのVTHが低く、最小値においては1V付近になってしまうものが多くあります。

そのため、VGSが0V~VDDの範囲でスイッチングすると、スプリアスゲートノイズのために予期しないターンオンや、VDSのdV/dtを引き起こすターンオンに対してマージンを確保できないという問題につながります。

そのため、SiC MOSFETではマイナス電圧のVGSが必要とされています。

SiC MOSFETゲートドライバーに求められるもの

これまで説明した内容からSiC MOSFETゲートドライバーではVGSをマイナス電圧から20V程度の高いプラス電圧まで駆動できるスイッチング能力が求められます。

このように広いターンオン遷移が求められるため、SiC MOSFETのスイッチング損失を押さえるためにSiCの内部ゲート容量を迅速に充電できるピークソース電流が必要です。

ターンオン現象全体が⊿t < 10ns 以内に発生するものとし、VGSのスイング全体が⊿VGS=30Vで、CISS=1870 pFとすると、必要なピーク電流は次の式からIG(SRC)=5.61Aと見積もることができます。

SiC MOSFETをターンオフするときは大量のピーク電流をシンクし、SiC MOSFETのCISS容量をできるだけ高速に放電しなければなりません。

さらに、低いVTHをもつSiC MOSFETのゲートをグランド未満にプルダウンしてその状態に保持する必要があるため、ゲートドライバーのシンク能力はソース電流よりも大幅に高くする必要があります。

onsemi社 SiC MOSFETとゲートドライバーラインナップ

onsemi社は650V耐圧SiC MOSFET以外に900V、1200V耐圧のSiC MOSFETと900V、1200Vハーフブリッジ、フルブリッジSiC MOSFETモジュールなど多数のラインナップをリリースしています。

onsemi社のSiC製品は特許取得済みの終端構造を備えており過酷な環境条件に対して優れた堅牢性を提供します。

また、SiC MOSFETゲートドライブに適した、大電流ドライブ能力を持ったゲートドライバーラインナップをリリースしています。

非絶縁型、ガルバニック絶縁型のラインナップ、シングル出力型、デュアル出力型のラインナップがあるので、

使用条件に合った製品を選ぶことができます。

最後に

本記事はonsemi社テクニカルノート TND-6237 “SiC MOSFETs: Gate Drive Optimization” を参照して作成しています。

お問い合わせ

今回紹介した内容及び製品にご興味がある方は、ぜひお問い合わせください。

オンセミ メーカー情報Topへ

オンセミ メーカー情報Topに戻りたい方は以下をクリックしてください。