外観検査に特化、エッジAIを活用した迅速でセキュアな製造現場DXが可能に ‐少ない正常データのみで学習、全てのAI動作がエッジデバイスで完結‐

製造業向けの外観検査に特化し、人手不足が叫ばれる製造現場における迅速な省人化やセキュリティリスク低減に貢献します。

「異常検知モデル」のポイント

•正常データのみで学習が完了

- 学習時に外部委託することの多いアノテーション作業が不要になるため、顧客等との秘密保持契約締結が不要です。

また、多量の不良品データの準備も不要な上、数秒で学習が完了するため現場への迅速なAI導入が可能です。

•学習と推論がともにFPGA搭載のエッジデバイス上で完結

- 画像データの社外送信が不要なため、情報漏えいリスクの低減、煩雑な秘密保持契約が要らず、省力化につながります。

- ネットワーク環境のない場所での利用も可能です。

•AIエンジニアがいなくても、現場で再学習可能

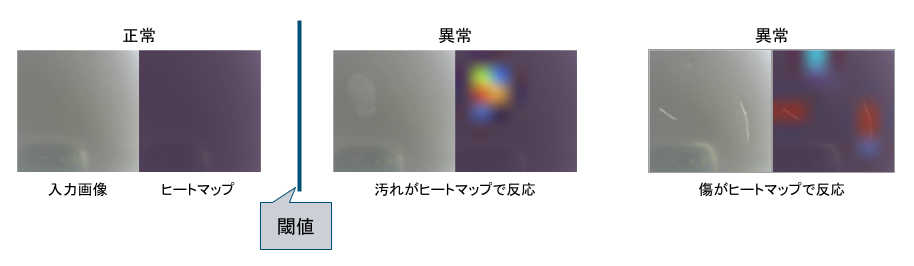

- ヒートマップで異常箇所を分かりやすく視覚化。AIの学習結果を保存して再読み込みが可能、

簡単に現場でのやり直しが可能となり、IT人材の確保が困難な企業でも利用できます。

IT人材の不足や設備にかかるコストを低減

慢性的な人手不足により、製造業の現場では自動化へのニーズが高まっています。検品などの外観検査ではAI活用が注目されていますが、IT人材の不足や設備にかかるコストの高さが課題です。また、AIの学習に必要な不良品データの収集が困難なことに加えて、消費者ニーズの多様化から多品種少量生産への対応が求められており、検査対象の変更に伴うAIの再学習にAIエンジニアのサポートを必要とするケースも想定されます。こうした対応への労力も導入ハードルとなっています。

LeapMindはこれまでも、ディープラーニングを使ったデバイスを世に広め、人々の生活を便利にするため、様々なエッジデバイスへディープラーニング機能を組み込むことができるAI推論アクセラレーターIP「Efficiera®」を開発してきました。この度開発した「Efficiera 異常検知モデル」は、独自の技術「極小量子化技術」などを活かし、現場での実用に即した、高セキュリティかつ運用しやすいAI外観検査を実現します。学習と推論がともにFPGA搭載小型エッジデバイス上で完結することに加え、学習が正常データのみで完了するという二つの特徴によって、様々な利点を持たせました。クラウドAIを利用する場合と比べて、検査対象の画像をデバイス外に出す必要がないため、社外送信時に懸念される情報漏えいのリスクを低減するほか、広帯域ネットワークやクラウドサービス利用料の削減にも貢献します。また、オンプレミスGPUサーバーを利用する場合と比べると、機材コストや設置スペースを理由とした拡張性への懸念も解決します。

さらに、学習は数十枚の正常データのみを使って数秒で完了し、多量の不良品データが不要です。正常データのみで学習できるため、アノテーション*¹ 作業が不要となり、また学習した不良しか検知できないというリスクを下げ、想定外の異常も検知することが可能です。再学習時の動作も簡便で、AIが異常と判定した箇所をヒートマップで視覚化するため、多品種少量生産ラインでもAIエンジニアのサポートを受けることなく現場で簡単に調整できます。学習結果は数MBのデータに保存して後から推論に利用できるため、誤った学習のやり直しも簡単です。IT人材の確保が困難な企業や、広帯域ネットワークを利用できない地方に製造拠点を持つ企業においてもスムーズなAI実用化を叶え、製造業のDXを後押しします。

*¹データに情報タグを付加すること。作業は社外に依頼するケースが多く、情報漏洩リスクとなり得る。

お問い合わせ

本記事に関してご質問などありましたら、以下より問い合わせください。