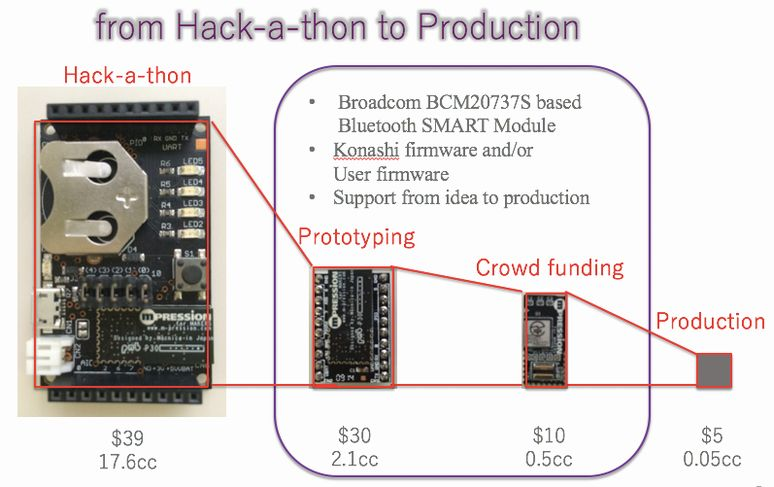

konashi/koshianを使ったプロトタイピングは、プロダクトの量産に対してもメリットを与えます。

現在各種マイコンボードのプラットフォームが一般発売されていますが、マイコンボードに搭載されているチップの入手性が悪いという理由で、プロトタイプから量産基板への以降時にチップを変えざるを得ず、量産基板で新しいチップで一からの設計のやり直しを行わなければならないという、メイカーズの製品化事例があります。

一方konashi/koshianを使うとこの問題をクリアすることができます。理由は以下のとおりです。

・koshianのコアBLEチップとしてアンテナ入のSiPモジュール、BCM20737Sを搭載。(マクニカオンラインストアで入手可能)

・チップ単体で技適取得済み。量産基板にそのままBCM20737Sを使えばアンテナの再設計が不要。

・プロトタイピングから量産基板まで同一チップが使用できるため、デザインの継承が可能。

以上のような特色からkonashi/koshianを使ってプロトタイピングを行うことで、プロダクトの量産までよりスムーズに開発を行うことができます。製品の開発ステージに合わせてkonashi, koshian+小型拡張ボード, koshian, BCM20737Sを柔軟に使い分けることで、価格、大きさ、設計の柔軟性のバランスを取りつつ開発を進める事ができます。