こんにちは。新人FAEのトンパです。

私は新卒でマクニカに入社し、製作実習でモノづくりを体験しながら回路設計や実装について学んできました。学生時代は有機化学を専攻しており、電気電子の知識が全くない状態からのスタートだったので、度々苦労しました。

そこで本記事では、私が製作実習でモノづくりを体験しながら回路設計や実装について学んだことを紹介しています。

そしてついに今回が、最終回です。前回(DC/DCコンバーターの評価)までの記事では、DC/DCコンバータ―にまつわることについて紹介しましたが、今回は、その他実習中に取組んだことをいくつか紹介します。こんなこともしていたんだと楽しんで見てください。

作製物の紹介

第1回~第5回の記事では、製作実習を通して回路設計について学んだことを紹介してきましたが、製作物については詳しく紹介できていませんでした。遅くなってしまいましたが、私が製作していたのはライントレースカーです。ライントレースカーとは、地面に描かれた線に沿って走行する自動走行車であり、今回は白い板の上に黒い線を引いたコースの上を自動走行する車を作製しました。

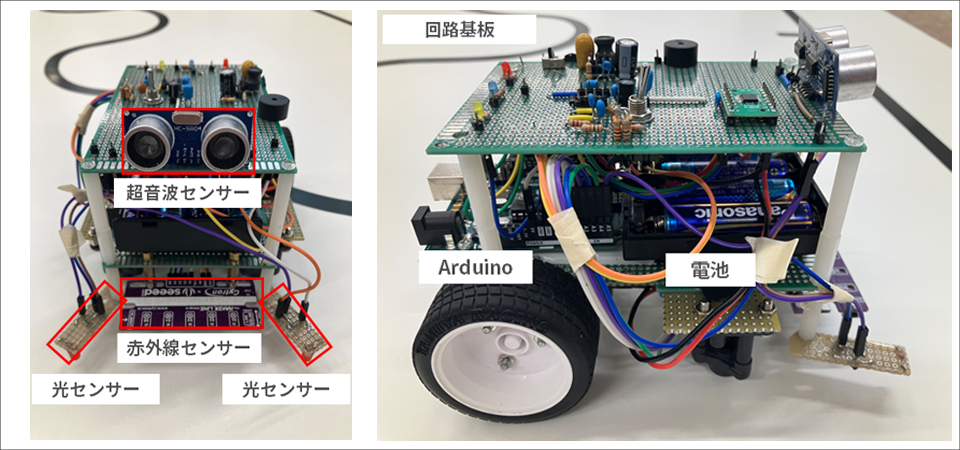

こちらが、実際に作製したライントレースカーです。肝となる黒い線を読取るセンサーは赤外線センサーおよび光センサーを用いました。また、コースの途中に設置される障害物を検知するために超音波センサーを採用しました。

車は2段構成にし、1段目にマイコン (Arduino) と電池を載せ、2段目にこれまで紹介していた回路基板を載せました。車体に関しては、あまり深く考えずにセンサー・マイコン間の配線をしてしまった結果、写真の様に配線が込み合い、不格好になってしまったのが反省点です。

プログラミング

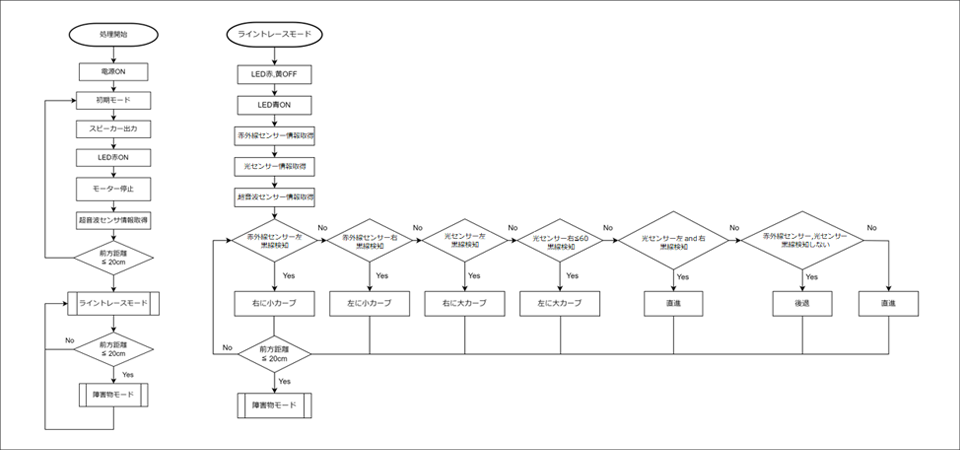

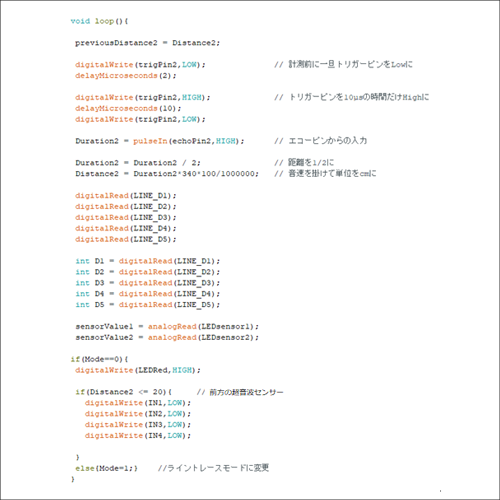

ライントレースカーを作製するためには、回路基板の作製だけではなく、プログラミングも必要になります。ライントレースカーの場合、各センサーでセンシングした信号を元にマイコンで車の走行を制御する必要があります。これまでプログラミングに触れてこなかった私は、なにをどう進めていけば良いのか全く分からない状態でしたが、まずはフローチャートを作成するべきであると教えて頂きました。

フローチャートとは、図2のようにプログラムの命令を書き並べた流れ図のようなモノです。フローチャートの作成には、プログラミングの処理の流れが理解できること、プログラミングをする際にスムーズにおこなえるなどのメリットがあります。

実際にプログラミミングに疎い私にとってフローチャートは道しるべのようなモノでした。

フローチャートがあることで、どの順番でどのようなプログラムを組めばいいのかイメージすることができため、なんとかプログラムを完成できたと思います。

それでは、実際にどのような制御をおこなったのか?となりますよね。

その制御内容を少し紹介させて頂きます。

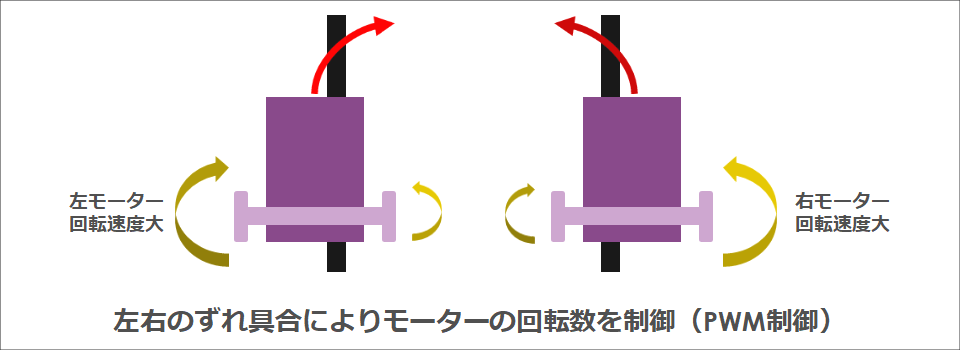

今回の制御で最も重要となるのはラインの検知とモーターの制御です。そこで、常にライン上を車が走行するために、前方のセンサーがラインに対してどの位置にあるかを検出し、その信号によりマイコンでモーターの制御をおこないました。

簡潔に言うと、右のセンサーのみが黒い線を検出している場合は左のモーターを強く、左のセンサーのみが黒い線を検出している場合は右のモーターを強く回転させるという制御をおこないました。そのような制御をより細かくすることにより、できるだけなめらかな走行をするようにしました。実際は少しガクガクな走行になってしまいましたが、しっかりとライン上を走ることができました。

こだわりポイント

続いては、今回ライントレースカーを製作するにあたり、私が工夫したポイントをご紹介します。

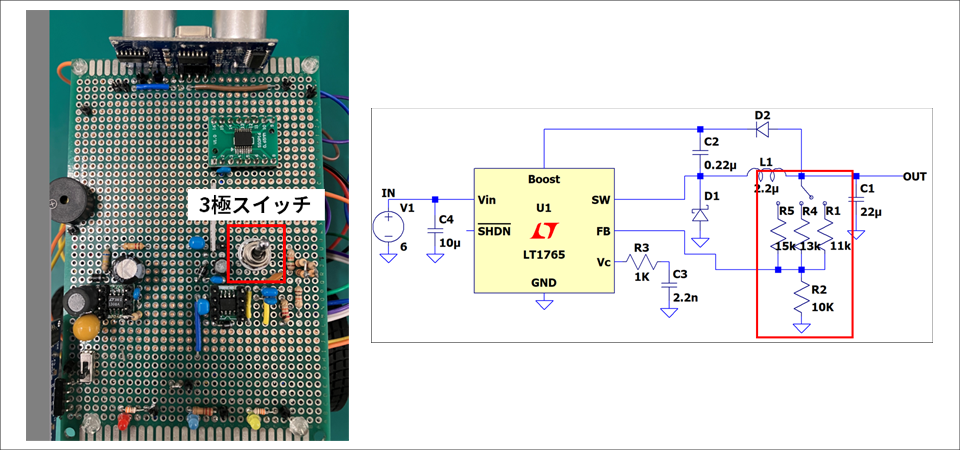

それは、マニュアル車のように手動で速度を変更させることです。車が好きということもありますが、速度変更をおこなうことによって、コースに最適な速度で走らせることが狙いでした。その方法は単純ですが、モータ前段のDC/DCコンバーターのフィードバック抵抗を3つ設け、スイッチによって3種類の電圧を供給できるようにしました。

「第5回 DC/DCコンバーターの評価」の記事でご紹介しましたが、オシロスコープで出力波形を確認すると狙い通り3種類の電圧を出力することができました。また、それに伴い車の速度も見事変化させることができました。そこまで難しい事をした訳ではないですが、狙ったことを達成できて嬉しかったです。

まとめ

最終話での紹介になってしまいましたが、私は製作実習でライントレースカーを作製し、無事完成させることができました。本研修では、メインである電源設計の他にもプログラミングなどを経験し、設計の大変さやモノを作る難しさを実感すると共にさまざまな学びがありました。今後は、今回の経験を活かし、設計者の方に頼って頂けるFAEになりたいと思います。

最後に、ここまでご覧頂いた皆様に感謝申し上げます。ありがとうございました!

人生初の回路設計までの道のり 記事一覧

・おまけ編