車載カメラの高解像度化が進み、小型化やノイズ低減が課題になる中、配線を簡素化できるPoC (Power over Coax) の採用が増えています。

車載カメラのPoCシステムを設計するにあたり「どのような電源選定がベストなのか知りたい」「車載カメラの小型化、ノイズ低減、発熱の解消ができるPoCを実現したい」と、情報を探している方も多いのではないでしょうか。

ここでは、車載カメラのPoCに必要な電源ICの種類、求められる性能、小型化・ノイズ低減・発熱解消に貢献するアナログ・デバイセズのソリューションを紹介します。ぜひ参考にしてください。

車載カメラのトレンドと付随する技術的課題

近年、車載カメラの市場規模が拡大しています。ADAS(先進運転支援システム)、DMS(ドライバー・モニタリング・システム)、置き去り検知、顔認証など、多様なアプリケーションに車載カメラが活用され、車両1台へのカメラの搭載数が増えています。

こうした中、車載カメラのトレンドの1つとなっているのが高解像度化です。これまで車載カメラの画素数は1~2MP程度でしたが、より鮮明な映像の実現に向けて、今後は2~5MP以上が主流になっていくと考えられます。

車載カメラの解像度トレンド

高画質化にともない、課題感が高まっているのが大容量データの伝送です。

アナログ・デバイセズは、大容量データを高速伝送できる通信インターフェースとして「GMSL(ギガビットマルチメディアシリアルリンク)」を提供しています。高画質映像をシンプルな回路で伝送できるため、注目されている技術です。

車載カメラのもう1つのトレンドが小型化です。多くの車載カメラを実装するために、カメラ1台あたりのサイズ制限が厳しくなっています。また、撮影を意識させないよう、フロントガラスの両端にあるAピラーなど、目立たない場所にカメラを埋め込む事例も増えており、一層の小型化が要求されています。

そこで期待されているのがPoCによる電源システムです。

おさらい ~PoCとは~

PoC (Power over Coax) とはどのような技術なのか、確認しておきましょう。

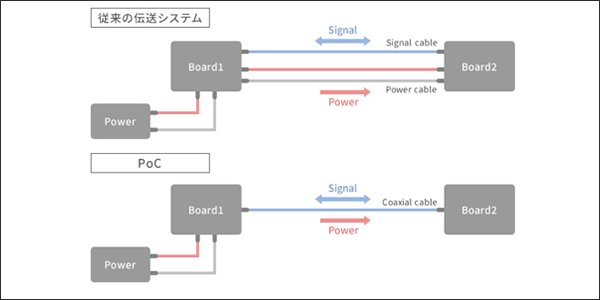

従来の電源システムでは、映像信号と電源をそれぞれ別のケーブルで伝送します。搭載されるカメラが増えるごとにケーブルが2本増えるため、小型化が難しく、ケーブルコストの増大、ケーブル重量による燃費悪化も課題となっています。

一方、PoCシステムでは、信号ケーブルに電源を重畳し、1本の同軸ケーブルで映像信号と電源を伝送します。電源用のケーブルを別に設ける必要がなく、接続用のコネクターも集約できるため、大幅に配線を減らすことができ、小型化、コスト削減、軽量化による燃費向上などを一気に実現できます。

PoCは、車載カメラの小型化に貢献する技術として注目され、採用が進んでいます。

■Power over coax

・同軸 (Coax) ケーブルを通した電力の伝送

・信号ケーブルに電源を重畳して、別途電源用のケーブルを設ける必要をなくした伝送方法

■対象

・GMSL, FPD Link, GVIF

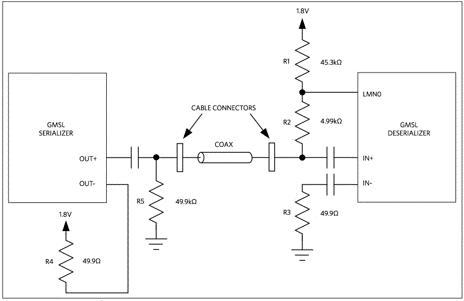

GMSL PoCアプリケーションでは、

-高速シリアルデータ

-UART/I2Cコマンド、

-DC電力

がすべて同軸ケーブル上に存在します。

⇒Power over coaxの電源はVoutが高く、ロードダンプを考慮すると降圧DCDCでは電力供給できません。

車載カメラのPoCに求められる電源ICの性能

車載カメラのPoCには、どのような電源ICが必要なのでしょうか。

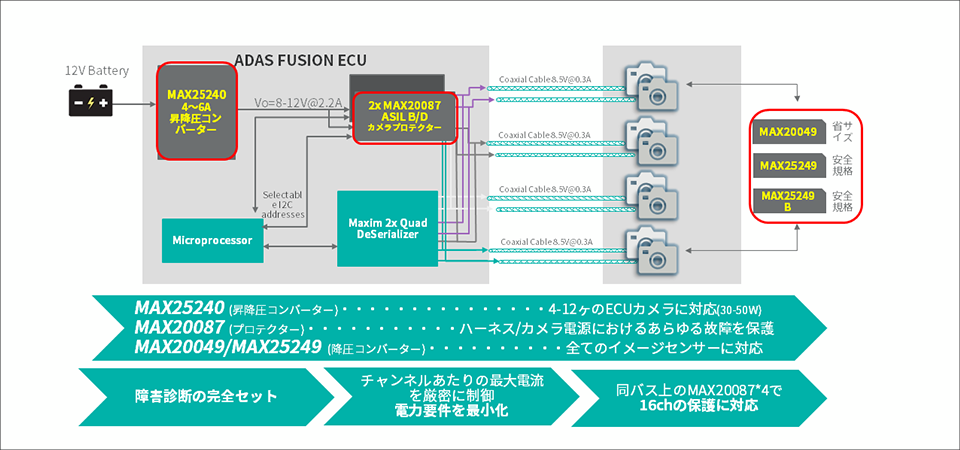

一般的に、車載カメラは2つの基板で構成されます。カメラを搭載するカメラモジュールと、映像処理などをおこなうカメラコントロールユニット (ECU) です。カメラモジュールで撮影された映像は、同軸ケーブル経由でECUに伝送されます。一方、電源はメインバッテリーからECUに入力され、ECUからカメラモジュールに伝送されます。

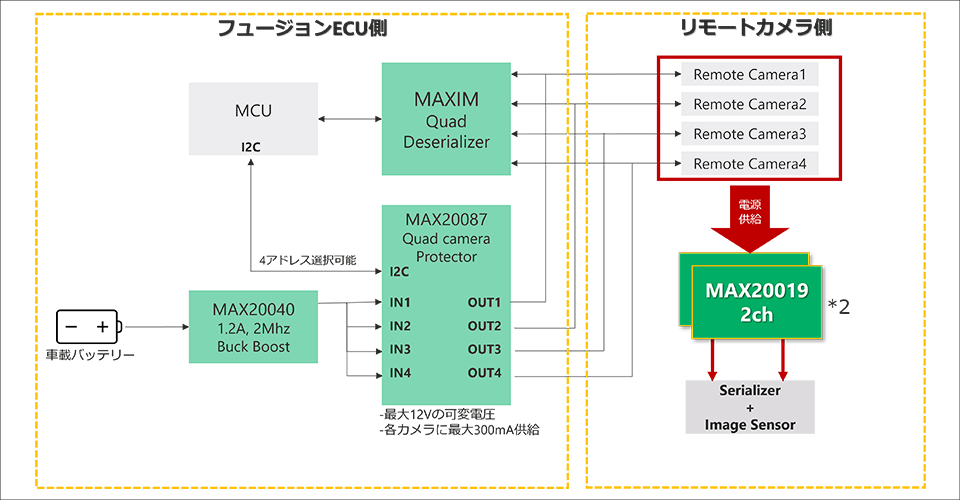

下の図では、左側がECU、右側がカメラモジュールを示しています。

赤枠で囲まれた部分が、PoCに必要な3種類のICです。ECUには、PoC用電源、カメラ電源プロテクターが置かれます。カメラモジュールにはカメラ用電源が置かれます。

それぞれどのような役割や性能が求められるのか、順番に紹介していきましょう。

<1.PoC用電源>

メインのバッテリーから受け取った電源を、PoC用に変換する電源ICです。通常、カメラモジュール側では電圧5V以下が求められますが、同軸ケーブルで電力供給する間に電圧降下が生じるため、PoC用電源ではやや高めの8-12V電圧を生成します。

このときに留意しなくてはならないのが、低温環境でのエンジン始動時にバッテリー電圧が大幅に低下するコールドクランク現象です。つまり、PoC用電源ではメインバッテリーからの電源を降圧するだけでなく、昇圧する動作が必要となります。そこで、PoC用電源には、降圧・昇圧ができるバックブーストコンバーターを利用します。

<2.カメラ電源プロテクター>

人の命に直結するADASや自動運転アプリケーションでは、ASIL B/C/Dといった高い安全水準に適合させるために、カメラの故障や断線を検知する保護機能が求められます。そこで、PoC用電源と同軸ケーブルの間に、カメラ電源プロテクターを配置します。

<3.カメラ用電源>

カメラ用電源としてDC-DCコンバーターを置き、カメラに必要な電源を生成します。カメラモジュールには、イメージセンサー、GMSLシリアライザーが搭載され、4ライン程度の電源供給が必要となります。

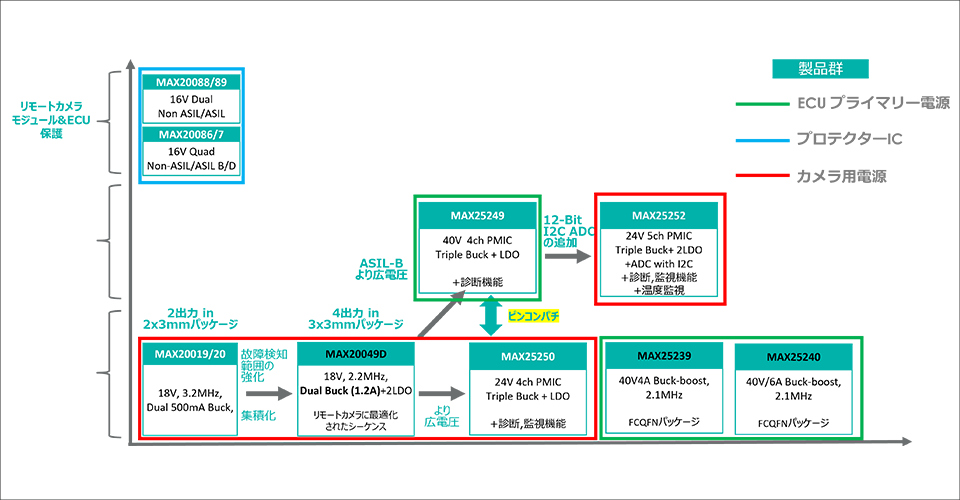

アナログ・デバイセズの車載PoC向け電源ラインナップ

それでは、具体的にどのようなソリューションがあるのか、紹介していきましょう。

アナログ・デバイセズでは、前述した3種類のICいずれも、複数のラインナップを持っています。

それぞれ、代表的なソリューションを紹介します。

【PoC用電源】設計しやすいバックブーストコンバーター「MAX25239/40」

PoC用電源ソリューションの一例が、昇圧・降圧機能を持つバックブーストコンバーター「MAX25239/40」です。入力電圧範囲が2-42Vと幅広く、車載プライマリー電源に求められる36V以上の耐圧を備えると同時に、コールドクランクにも対応できます。

一般的なバックブーストコンバーターでは、4個の外付けFETが必要となるため、基板が広がってしまい、設計も複雑化しがちです。また、配線が長くなるため、放射ノイズが大きくなります。

MAX25239/40では、FETがすべて内蔵されているため、シンプルな配線で設計でき、小型化を容易に行えます。また、高効率で、ノイズ性能も優れているため、発熱しにくい低ノイズの車載PoCを実現できます。

【カメラ電源プロテクター】ASIL B/C/Dに対応できる「MAX20086~89」

カメラ電源プロテクターの代表例が、ASIL B/C/Dに対応する「MAX20086-89」です。

過電圧・低電圧診断、短絡診断など、さまざまな診断機能を備えており、I2Cインターフェース経由での状態監視が可能です。

MAX20086~89を置くだけで、ADASなどの信頼性が求められる車載アプリケーションにも最適な保護機能を、容易に実装できます。

【カメラ用電源】極限まで小型化を追求できる「MAX20019/20」

カメラ用電源ソリューションの一例が、2チャンネル出力、17V耐圧のステップダウンコンバーター「MAX20019/20」です。カメラ用電源に求められる16-17V耐圧に対応しています。

デバイスのサイズが2mm × 3mmと非常に小さいため、コンパクトな回路設計が可能です。固定出力電圧を豊富なオプションから選択できるため、電圧調整のための外付け部品を減らして、極限まで小型化を追求できます。ノイズを低減できるスペクトラム拡散機能も備えています。

小型化がシビアに求められるカメラモジュールに最適な電源ソリューションです。

下図は、MAX20019を2個利用して、4ラインの電源を供給する構成例です。4チャンネルのソリューションでも実現できますが、2チャンネルのソリューションを2個使うことで、柔軟性が向上し、部品のレイアウトが容易になっています。

本記事では、車載カメラのPoCについて、必要な電源ICの種類、求められる性能、アナログ・デバイセズの代表的なソリューションを紹介しました。

アナログ・デバイセズのPoC向けソリューションは、車載カメラの小型化、ノイズ低減、熱対策に貢献します。ご紹介したソリューションの評価ボードを取りそろえています。お気軽にお問い合わせください。

アプリケーション例

・ADAS(先進運転支援システム)

・車載カメラモジュール

商品の購入はこちら

メーカーサイト/その他関連リンクはこちら

お問い合わせ

本記事に関してご質問がありましたら、以下よりお問い合わせください。

アナログ・デバイセズ メーカー情報Topへ

アナログ・デバイセズ メーカー情報Topに戻りたい方は以下をクリックしてください。