振動計測をすることでどんなことができる!?

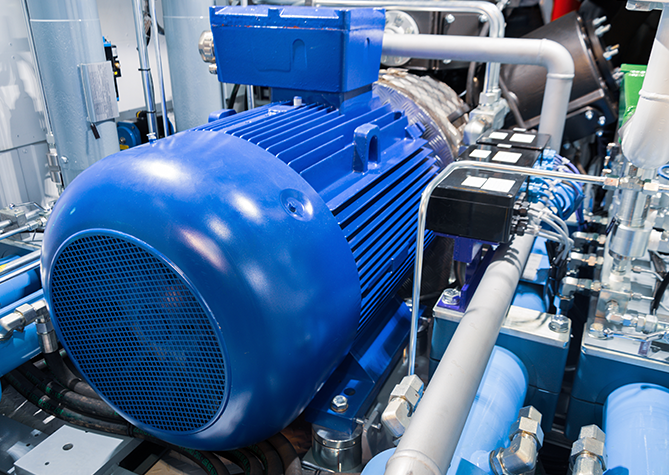

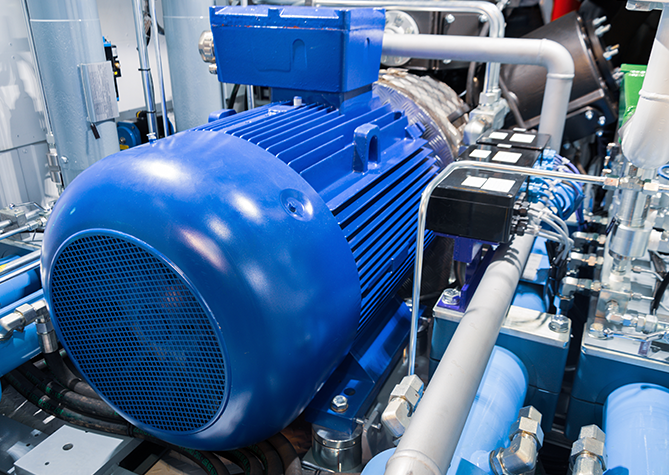

振動計測というと、真っ先に産業機器として工場やFA機器で求められるもの、と思われるかもしれません。当然ながら、工場などで使用されている機器には駆動させるためのモーターやエアー管理としてファンやコンプレッサーなどが用いられており、正常時でも振動が発生しています。

ただし、この振動によって機器の耐久性・信頼性に影響を及ぼす可能性や、破損・異常停止などが機器の寿命や動作不具合などを引き起こします。また、産業機器だけではなく、ビルディングや構造物建築など私達の日常においても非常に身近なところに振動が存在していますが、異常停止や故障する前に振動計測をすることで事前に大きな問題を回避することが重要になってきます。また、振動を常に人を介して記録、メンテナンスすることなく、リモートで計測・監視することは巡回要員などの負荷や工数の削減にも繋がってきます。

今回は、「Cloud接続で手軽に低価格で振動計測のPoC検証」をおこなうソリューションを以下のポイントからご紹介します。

1. 予知保全の必要性

2. 振動計測を手軽にCloud接続するには?

3. どういうパッケージが用意されている?

4. 実際の使用例は?

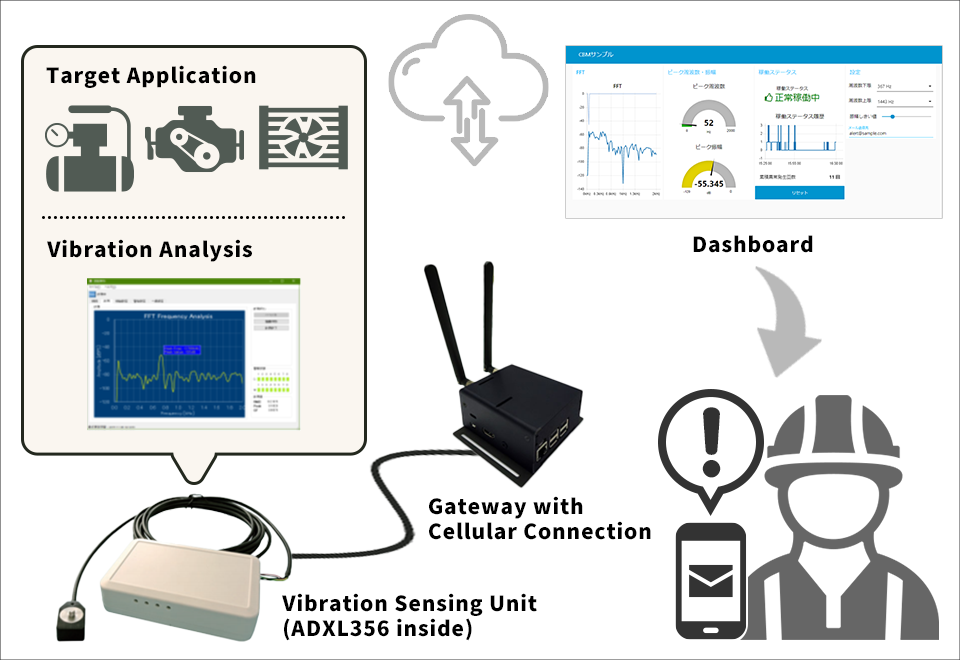

システム構成

1. 予知保全って?

予知保全の位置づけ

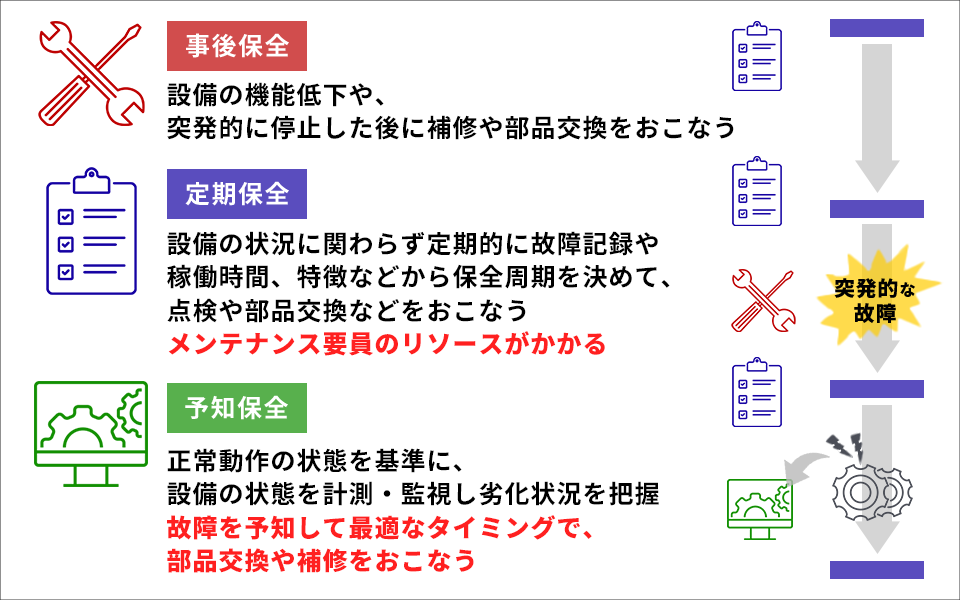

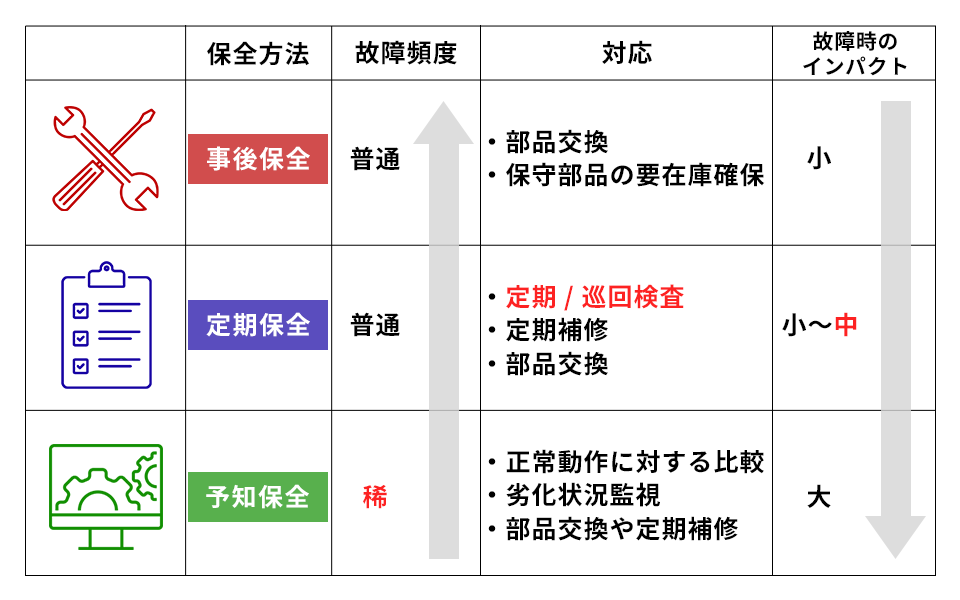

保全と呼ばれる保守業務は大きく分けて3つのタイプがあります。

(1)事後保全:設備の機能低下や突発的に停止した後に補修や部品交換をおこないます。つまり、何か異常が発生してから初めて対応をおこなうことになります。

(2)定期保全:設備の状況に関わらず、定期的に故障記録や稼働時間、機器の特徴などからメンテナンス周期を決めて、点検や部品交換などをおこなう手法になります。

(3)予知保全:正常動作の状態を基準にして、設備の状態を計測・監視することで劣化状況を把握したり、故障を予知して最適なタイミングで、部品交換や補修をおこなう。

予知保全の効果

また、下記にそれぞの保全の種類とインパクトをまとめましたが、予知保全には以下のケースの時に効果を発揮します。

・故障頻度は稀だが、故障時のインパクトが大きい設備や機器がターゲットになります。

・振動計測の対象は、振動を伴う機器全てになりますが、上記の様に故障インパクトが大きいケースや、メンテナンス要員のリソースが求められる場合でも効果の可能性があります。

2. 手軽にどう振動計測をおこなうか?

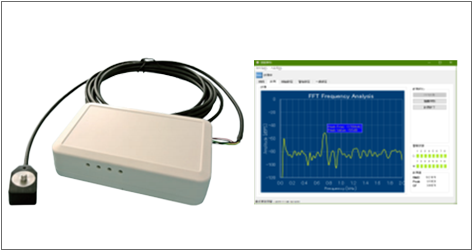

(1)今回のパッケージソリューションには、ユークエストの振動解析装置 (EMQuest-VA) を使用して機器の振動周波数を解析することで、アンバランス、ガタ、基礎不良、転がり軸受損傷などの機器異常が発生しているかを判断できます。振動計測のピックアップには、アナログ・デバイセズ社の3軸MESM加速度センサー (ADXL356) を使用し、低ノイズ密度 (80μg√Hz)、高G (±20g) に対応しています。

・MEMS加速度センサーを採用することで低価格を実現

・加速度を取得し速度とFFT(高速フーリエ変換)値を計算

・設定された閾値を超える振動を計測した際に接点 (Digital Output) により警報を上げることが可能

・SDカードにデータを保存して過去の状態を監視。警報が上がる前後のデータだけを残すことも可能

・PCを接続してリアルタイムでFFT解析結果の表示が可能

(2)振動計測のCloud接続にはCANDYLINEのGateway (CANDY Pi Lite) とクラウド開発環境&実行環境 (CANDY EGG) を使用しています。またアプリケーションはオープンソースなので自由に入手できます。

<Gateway>

・Raspberry Pi3 Model B+搭載

・4G/LTE/3G対応セルサーモジュール搭載(Docomo、Docomo系MVNOに対応。他キャリアは随時動作検証)

・通信速度(標準接続時:下り上り共に最大460Kbps)

<Cloud>

・クラウドのデータベース構築、デバイス通信、ダッシュボード機能

・5GBまでサーバー使用が可能

・ソースコード(GitHubより入手可能)

3. パッケージの種類

|

CbM Kit |

Gateway Pack |

Cloud Pack |

|

|

特長 |

まずは手軽に振動計測を開始 |

サーバーやCloudは 自社構築で振動計測を検証 |

CloudまでPackになった振動計測PoCパッケージ |

|

EMQuest-VA |

● |

● |

● |

|

Gateway |

● |

● |

|

|

CANDY EGG |

◎ (※1)(※2) |

||

|

SIM |

★ (※1) |

||

|

販売価格(●)(※3) |

¥99,000 |

¥148,000 |

¥148,000 |

|

CANDY EGG(◎) |

¥35,760(年額) |

||

|

SIM(★) |

¥12,000~(年額算出) (契約内容次第) |

||

|

想定初期費用 |

¥99,000 |

¥148,000 |

¥195,760~ |

|

Package内容 |

・振動計測装置のみ |

・OS&アプリインストール、 ・EMQuest-VA動作アプリ、 ・LTE通信用SW |

左記に加えて、 ・回線設定 ・Cloud接続へのセットアップ ・メール配信設定 |

※1:お客様での直接契約になります ※2:5GBまで使用可能 ※3:現状の予定販売価格

4. アプリケーション例

・工場でのモーターやファン、コンプレッサーなどでの振動計測

・築後経過しているビルやマンションなどでの既設ポンプやモーターなどのメンテナンス

・リモートで監視やメンテナンス巡回の軽減

おすすめ記事/資料はこちら

メーカーサイト/その他関連リンクはこちら

お問い合わせ / お見積もり

本製品に関してご質問、見積もりの希望がありましたら以下より問い合わせください。

アナログ・デバイセズ メーカー情報Topへ

アナログ・デバイセズ メーカー情報Topページへ戻りたい方は、以下をクリックください。