半導体、ネットワーク、サイバーセキュリティ、AI/IoTにおけるトータルサービス/ソリューション・プロバイダーの株式会社マクニカ(以下マクニカ、本社所在地:神奈川県横浜市、代表取締役社長:原 一将、資本金111億94百万円)は、この度、DXプロジェクトを推し進める製造業を対象に、

「DSF-MES導入体験サービス」の提供を開始することを発表いたします。

近年、新型コロナウイルス感染症(COVID-19)や人材不足など、製造業を取り巻く環境は厳しさを増しています。

顧客ニーズの高まりから変種変量生産への対応や、コロナ禍による工場停止や生産計画の見直しなど、様々な環境変化に臨機応変に対応していくことが求められています。

そのような中、これらの課題を解決すべく、IoTやAIを活用した生産現場のDX化に取り組まれる企業が増えてきました。

製造業DXについては、データ収集のインフラが重要であり、IT(Cyber Layer)とOT(Physical Layer)の交点にあるMES(製造実行システム)の導入が必須となります。

MESの機能だけをみれば、様々なシステムに実装されており、代替する機能としては何かしら持たれている企業がほとんどですが、個別に構築されてきた故に体系化されていないケースが多く見受けられます。

これが、製造業DXを実現する上でMES刷新の検討を難しくしている要因であり、MESの検討を進められているお客様からは、レガシーシステムからの刷新において、何から始めればよいのか分からないという課題が発生します。

マクニカでは、MESをご検討いただいているお客様を対象に、「DSF-MES導入体験サービス」の提供を開始します。

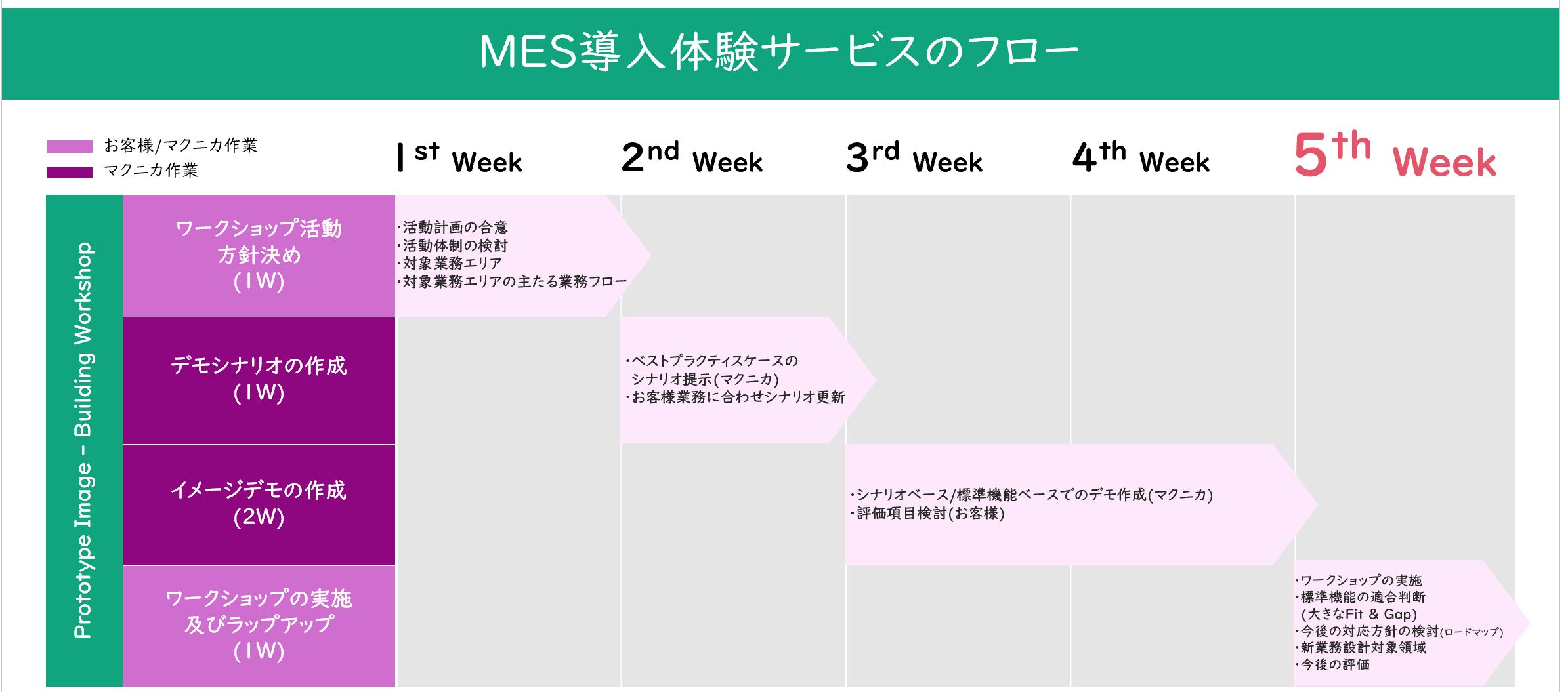

このサービスは、Fit to StandardのアプローチからMES導入をご検討いただく上で、非常に有効な手段となっており、シーメンス社MESパッケージを活用したマクニカ独自のメソッドによるワークショップを通じて、短期間でMES導入時のイメージと効果の確認ができます。

現状の把握から、ベストプラクティスのシナリオに合わせたデモをすることにより本当に必要な自社要件を定義、MESパッケージの適合性の判断が可能です。

これにより、MESの導入検討時に課題となる、MES導入のイメージをあらかじめ想定することができるため、よりスムーズにプロジェクトを推し進めることが可能となります。

DSF-MES導入体験サービスでできること

●デモによるMES導入イメージの早期想定と投資判断

●将来の拡張性を視野にいれた構想設計

●構想設計にそったスムーズなDXプロジェクト推進

マクニカでは、これまで300件以上の製造業DXを支援させていただいた経験から、MES導入がDXプロジェクトを成功させる上で有効であると考えております。

実行可能な構想設計を行うIT/OTプロフェッショナルに加え、期待値と負荷の高いDX人材の育成を支援するナレッジによって、引き続き製造業DXを推進される企業様を支援してまいります。

「DSF-MES導入体験サービス」の詳細については、マクニカウェブサイトの専用ページをご覧ください。

https://www.macnica.co.jp/business/ai_iot/products/service/136480/

なお、本サービスについては、2021年7月14日より開催されます「SIEMENS Realize Live Japan 2021」にて展示を予定しています。

<開催概要>

名 称:・難解なものづくりDXのはじめの一歩~活路を開く、「人」が中心の具体的アプローチ~

・ケイパビリティを最大化させDXを突破せよ~ビジネス人材がDX人材に変わるシンプルな方法~

日 時:2021年7月14日(水)9:30~(オンデマンド配信)

参加費:無料(事前登録制)

主 催:シーメンス株式会社

参加申し込み方法・開催内容はWebサイトをご覧ください。

https://event.sw.siemens.com/ja-jp-realizelive

※本文中に記載の社名及び製品名は、株式会社マクニカおよび各社の商標または登録商標です。

※ニュースリリースに掲載されている情報(製品価格、仕様等を含む)は、発表日現在の情報です。

その後予告なしに変更されることがありますので、あらかじめご承知ください。