\ こんな方におすすめ /

- 生産計画と実績にズレが…作業効率を改善したい!

- 作業のボトルネックを正しく把握したい!

- 組み立て工程に起因する品質のばらつきやロスの改善方法を知りたい!

組み立て工程のQCD改善にむけたアプローチ

◆まずは概要を知りたいという方・・・ぜひこのままグラレコをお読みください!

◆最初から全部知りたいという方・・・当日の↓ 講演動画 ↓をご覧ください!

こんにちは、Sambaです!

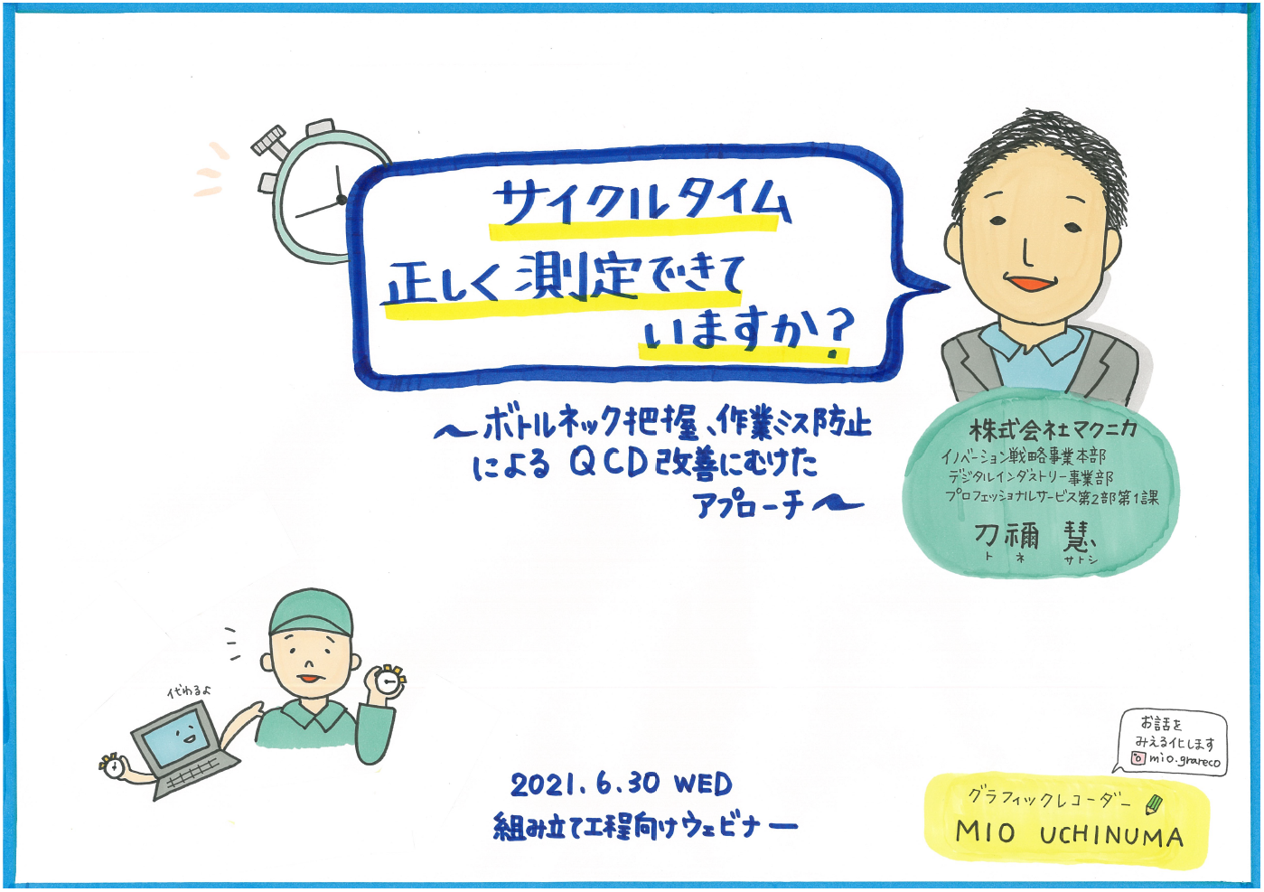

本コラムでは、2021年6月30日に行われたオンラインウェビナー

『サイクルタイム正しく測定できていますか? ~ボトルネック把握、作業ミス防止によるQCD改善にむけたアプローチ~』についてお届けします♪

ウェビナーでは、組み立て工程におけるQCD改善の糸口となる、ボトルネック改善や生産計画最適化、品質のばらつきとロスの改善のアプローチ方法をご紹介しました。

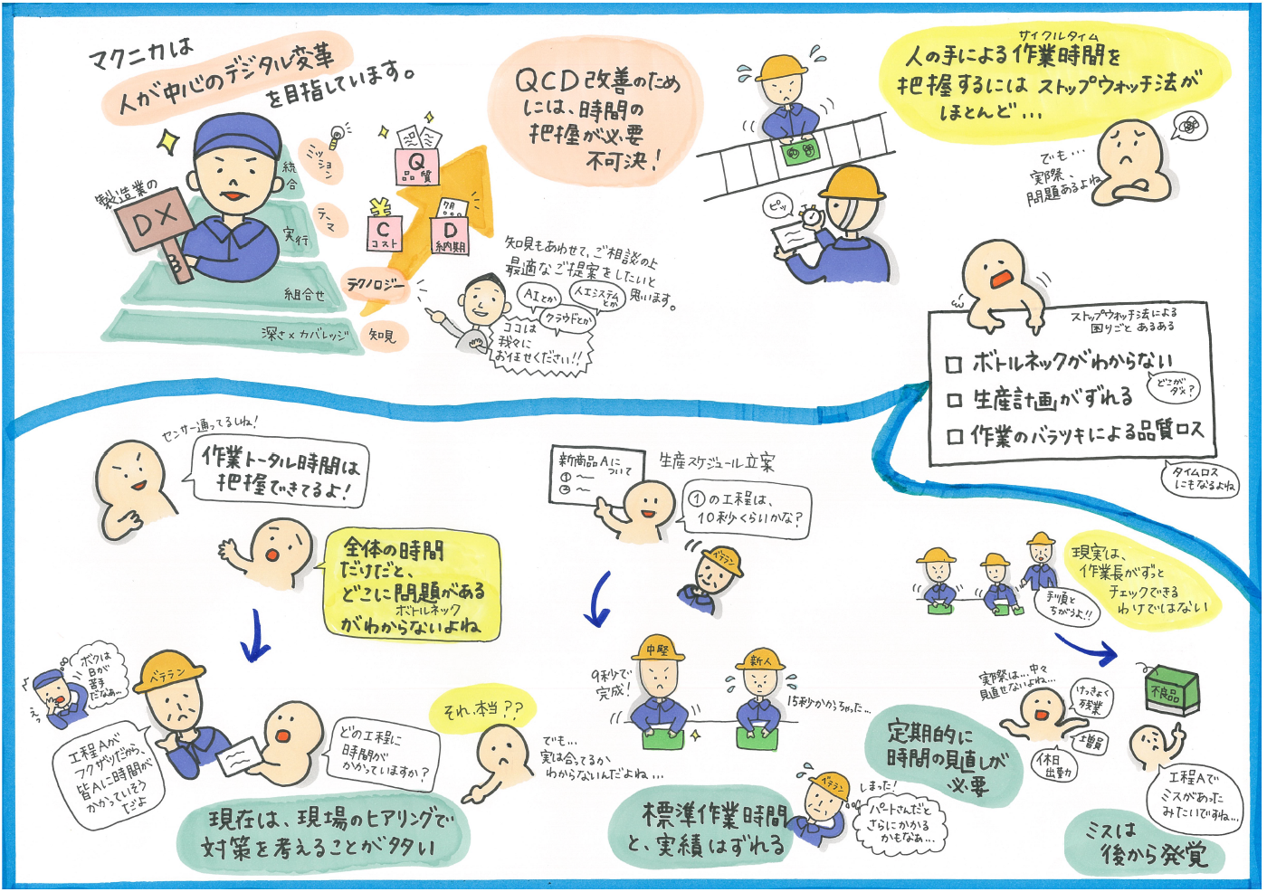

ものづくりにおいて “リードタイムの短縮 ” は永遠の課題ともいえるかと思います。なかでも、組み立て工程においてはサイクルタイムの短縮に取り組まれている方も多いのではないでしょうか?

しかしいざ、ストップウォッチを使って測ってみたものの

・不定期に取得しているため、改善ポイントが正しいのか分からない

・改善結果を定量的に判断することが難しい

・最適な生産計画が立てられずにいる

といったお声をよくお聞きします。

今回のウェビナーでは、そんなお悩みを解決する手法をお届けしました!

「最先端のテクノロジーをキャッチアップしたい」という方にも分かりやすいよう、それぞれのポイントをピックアップしてグラレコでお伝えしていきたいと思います。

それではいきましょう♪

よくある組み立て工程現場の課題

◆◇ひとことコメント◇◆

ストップウォッチを使ってみたものの、正しくサイクルタイムを計測できていないと、さまざまな問題につながる可能性があります。改善したことが正しかったのか、効果があったのか判断できないというのは、不安ですよね。

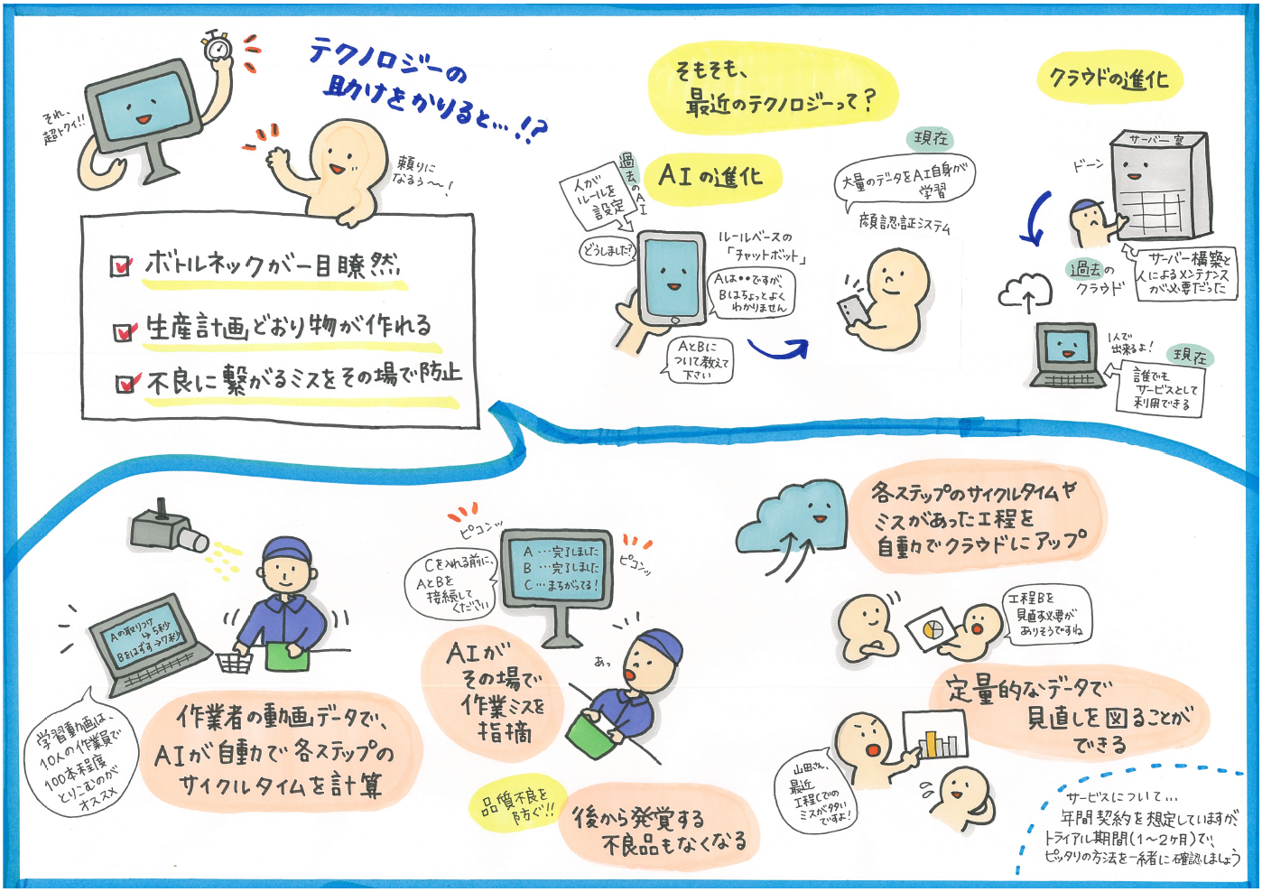

テクノロジーの進化と課題へのアプローチ

◆◇ひとことコメント◇◆

講演では、実際の作業でサイクルタイムの計測や作業ミスの警告が出されるデモ動画をご覧いただきました。ご興味のある方は、ぜひ講演動画もチェックしてみてください!

みなさまの疑問に、リアルタイムに回答!

最後のセッションでは、ウェビナー中にお受けした皆様のご質問に回答させていただきました!時間が足りずに回答できなかった内容も、ここでお届けしていきたいと思います♪

※グレーの範囲内をスクロールしてご覧ください

|

Q |

紹介頂いた事例は作業動画が一人しか映っていませんでした。実際の現場は人が入り乱れていますが、複数人の人の移動がある現場でも一人の作業を行っていない時間の判別は可能なのでしょうか? |

|---|---|

|

A |

背景に移動する他の人影が映り込む場合は、それらを無視するようにAIモデルを学習させるために、複数の人が移動する背景パターンで学習用動画を撮影していただくことで吸収できると考えています。 |

|

Q |

作業の順番間違いや抜け漏れは、どれくらいの精度で検出できるのでしょうか? |

|---|---|

|

A |

前後の作業手順が異なる作業であることをカメラでとらえることができれば、基本的には正しく判別可能です。 |

|

Q |

導入する際はどのような機材、環境等が必要でしょうか? |

|---|---|

|

A |

以下の環境が必要になります。

|

|

Q |

現場作業はかなりのバリエーションがあります。作業を行っていない時間の自動測定には作業を事前に学習する必要があるのでしょうか? |

|---|---|

|

A |

作業ごとに事前に学習する必要があります。例えば、製造する製品ごとに作業手順が異なる場合、製品Aの作業と製品Bの作業それぞれについての学習が必要です。 |

|

Q |

AIの学習はどのように行うのでしょうか? |

|---|---|

|

A |

事前に撮影した学習用動画をクラウドにアップロードしていただき、それに対して各作業サイクルへのアノテーション(作業手順のラベル付け)を行うことで、AIモデルの学習はクラウド上で1クリックで行うことができます(学習・モデル生成までに時間はかかります)。 |

|

Q |

AIの学習はどの程度の期間、サンプルが必要でしょうか? |

|---|---|

|

A |

対象となる作業ごとに100サイクル分の動画が推奨になります。 |

|

Q |

AIやプログラミング等の知識、スキルはどの程度必要でしょうか? |

|---|---|

|

A |

AIやプログラミングの知識、スキルは不要です。Webブラウザでクラウド環境にログインしてダッシュボードをご覧いただいたりしますので、ある程度のITリテラシーは必要と考えています。 |

|

Q |

このサービスは、短期間の利用できますか? |

|---|---|

|

A |

年間ライセンス契約となりますので、1年単位でご利用いただくことができます。 ご検証・ご評価のためのトライアルについては個別にご相談を承っています。 |

|

Q |

AIはどの作業をしているかを、姿勢を見て判断しているのでしょうか? |

|---|---|

|

A |

姿勢推定ではございません。 |

|

Q |

事前に作業を覚えさせる必要がある、とのことですがそのマスタは作業者ごとに必要でしょうか?それともマスタとして一人分の作業を記録させるだけでいいのでしょうか。 |

|---|---|

|

A |

学習は作業者ごとに行う必要はございませんが、複数の異なる作業者で学習用動画を撮影することで作業者が変わることによる差異を吸収する仕組みになっています。通常、10人で10サイクルずつの100サイクル分の学習用動画が推奨されています。 |

|

Q |

検知できない作業があった場合の処理はどのようになるのでしょうか。その手順を実行していない、としてエラーになるのでしょうか。 |

|---|---|

|

A |

事前に登録していない動作(作業)を行った場合、その作業や時間は「その他」の時間として計測させることができます。その後に計画している次の手順を実施すればエラーとせずに引き続き作業を続けることができます。 |

|

Q |

例えば、手順が入れ違っても問題ないネジの締め付け順序を作業者が変えて作業してしまった場合、このソフト上はエラー扱いになるのか、問題無しとできるのか、教えていただけますでしょうか。 |

|---|---|

|

A |

ネジ止めなど順不同で実施可能な作業については順不同として扱うことが可能です。 |

|

Q |

AIが検知する作業ミスはどのようなロジックでしょうか?例えば締結不備やボルトのサイズ間違いを検出できますか? |

|---|---|

|

A |

ネジ止めを行ったかどうかは検知できますが、ゆるみがあったかどうかまでは判定が難しいと考えています。ボルトのサイズ違いについては異なる場所からボルトを取り出すシーンから映っていればそれで判別可能です。 |

|

Q |

作業者が現場から離れることが多いのですが、一度離れて戻ってきた場合、一日の作業が正しく記録できるのでしょうか? |

|---|---|

|

A |

作業の途中で手を止めて作業場から離れていただいても、戻ってきてから作業を継続していただければ正しく計測可能です。 |

|

Q |

ベルトコンベアに乗って流れてきたもの対して、作業を行う場合に対応していますか? |

|---|---|

|

A |

基本的には対応可能と考えています。作業位置にばらつきが生じる場合は、ばらつきのある映像を学習用の動画としてご使用いただくことで差分を吸収できます。 |

|

Q |

今後のメンテナンス費用など概算で結構ですのでお教えください。 |

|---|---|

|

A |

買い切りの製品ではなく年間ライセンス契約となります。契約数に応じた価格設定になっていますので、個別にご相談いただければと思います。 |

イベント後のお客様の声

「映像を用いた具体例は非常にわかりやすく良かった。社内導入イメージが検討しやすい。」

「AIカメラを活用しての作業測定、異常確認等、技術の進歩含めてとても参考になりました。」

「最新の技術動向を知ることができ、参考になった。」

おわりに

いかがでしたか?

組み立て工程のQCD改善を目指す皆様が、「AI活用を具体的に検討してみよう」という取り組みのきっかけになれば嬉しいです!

とはいえ、AIはあくまで手段の一つ。

データがあるかどうか?AIを作れるか?の前に、本来の目的・課題をいかに設定するか、が一番重要だったりします。

課題整理に息詰まっている方、自分のアイデアを誰かに相談してみたい!という方は、ぜひ弊社プロフェッショナルにご相談ください★