デジタルトランスフォーメーション(DX)において核となるデータ収集のポイントは何でしょうか。

そして収集したデータの有効な活用方法にはどのようなものがあるのでしょうか?

マクニカは、数多くのDXプロジェクトに伴走・支援しています。

そこで培った経験をもとにここでは、「DXプロジェクトの成功確度を高めるポイント」と、さまざまなプロジェクトのベースとなる「データの利活用」における注意点を解説するとともに、どのように対処すべきかについてご紹介します。

講演者情報

株式会社マクニカ

イノベーション戦略事業本部 AIビジネス推進部

デジタルオファリング課

芳賀 妙孝

製造業のDX推進プロジェクトを妨げる障壁とは

働き方改革の推進や新型コロナウイルスへの対応などを背景に、企業のDXが大きく加速しています。

その流れは製造業においても同様であり、データやAIを活用した業務改革が多くの企業で検討されています。

「製造業において、ここ数年でAIに関する考え方が劇的に変化していると感じています。それに伴い、DX担当者に求められる役割の範囲は拡がっているのではないでしょうか」とマクニカの芳賀は話します。

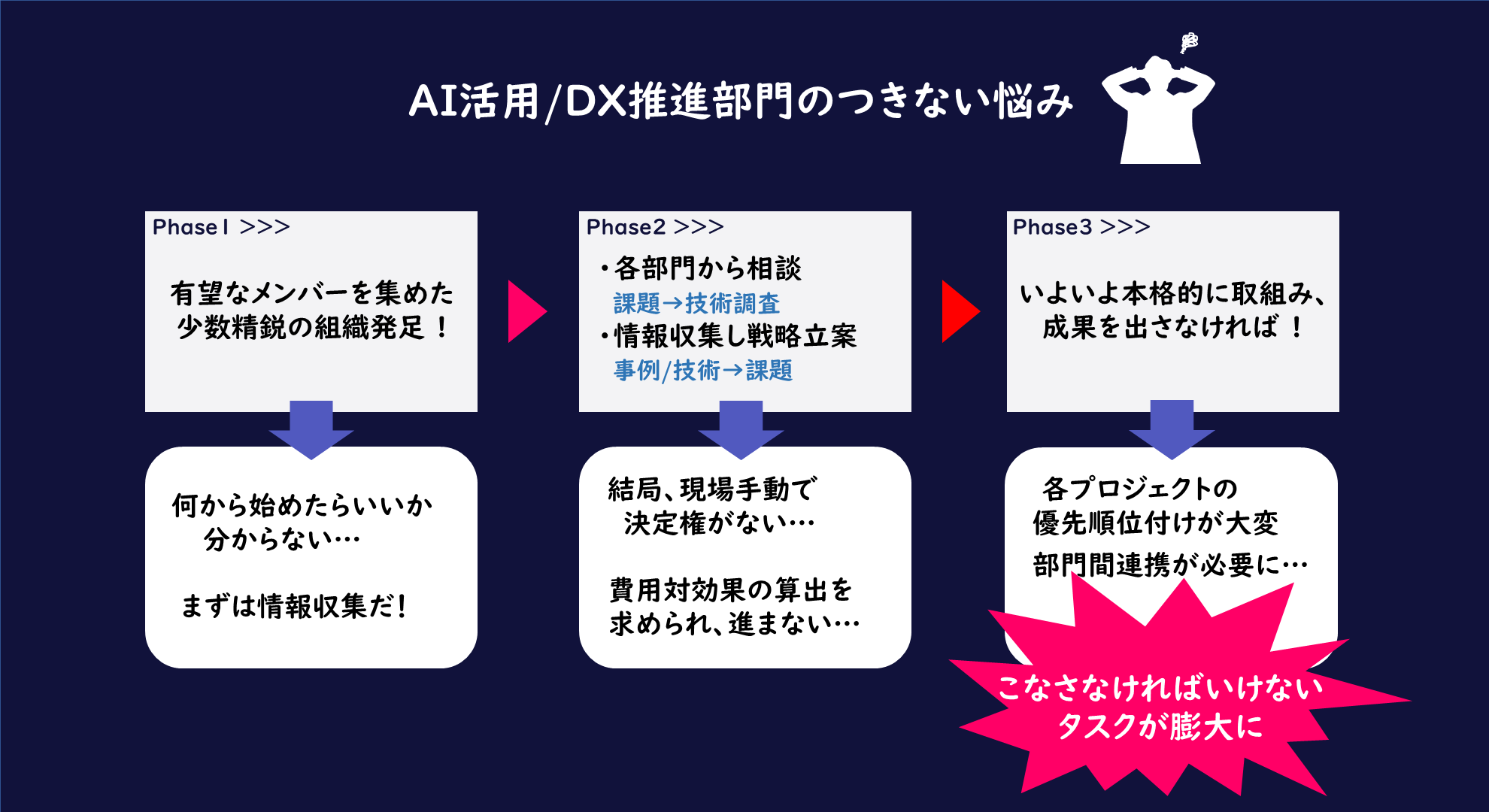

AIの活用、DX推進にアサインされると、当然のことながら成果が求められることになります。

数多くあるプロジェクトの中で、費用、効果、バランスなどから判断を迫られます。また、本格的にプロジェクトを立ち上げると部門間連携や業務フローの整理など、以前は重視されていなかったタスクが積み重なるようになりました。そして、DX推進部門が単独で解決できることは、極めて少なくなっているはずです。

DX推進部門に求められる役割は増え続けています

そして昨今のDXプロジェクトは、実運用を見据えて開始される取り組みが多くなってきました。どのようなことが障壁となり、どうすればその壁を乗り越えられるのでしょうか。

「DXプロジェクトにおいてつまずきやすいポイントの一つに、ビジョンやロードマップが描けていないということがあげられます。そのため、目的や優先順位を見失ってしまい、途中でプロジェクトが止まってしまうケースが後を絶ちません。中には、社内外の関係者間で役割分担を明確になっておらず、連携をスムーズにできていないプロジェクトも多くあります。DXを進めるうえで必要な知見や技術を持つ人材も不足していることからプロジェクトがうまく軌道に乗らないケースもあります。」

「DXを妨げる壁を乗り越えるためには、個別に走るプロジェクト間や部門間の連携や統合をはかり全体計画を立てていくことが必要になります。

解決方法として、人材を社内で育成するか、外部パートナーを活用するか、そのどちらも行うか、3つのパターンが考えられます。社内の人材だけで乗り切るケースはかなり稀で、専門知識を持っているパートナーの知見を活用するケースが多いです。ただし、パートナーと同じレベルで会話できる人材がまず必要になるので、並行して人材育成に取り組む企業がほとんどです」(芳賀)

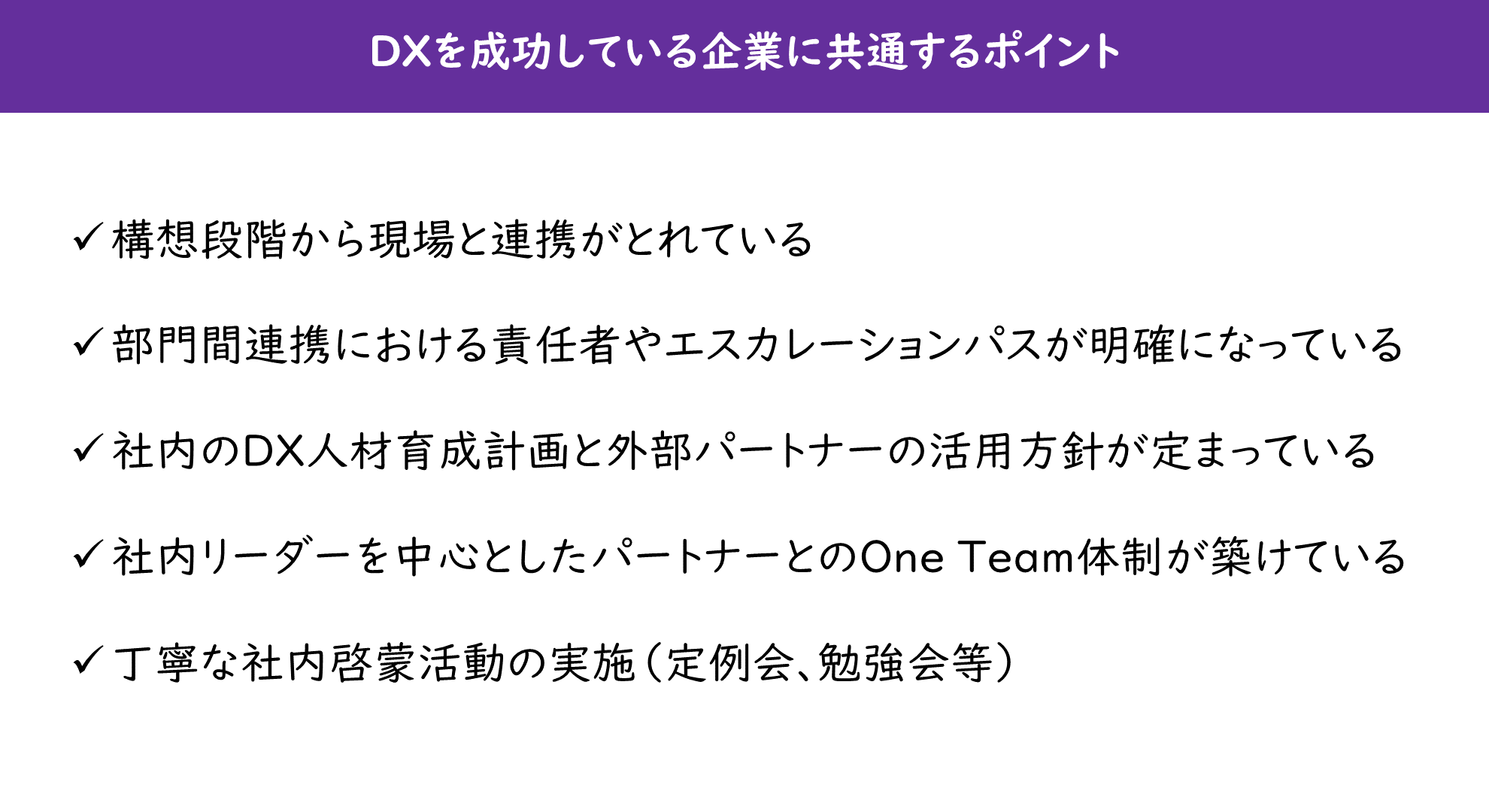

DX先進企業に共通する5つの成功ポイント

DX推進に行き詰まる企業が少なくない一方で、AIの実運用まで進み、成功している企業もあります。成功企業に共通するポイントは5点あると芳賀は話します。

成功企業の共通ポイントを取り入れることが、DX推進の近道に

ポイントの中の「部門間連携における責任者やエスカレーションパスが明確になっている」について「これは立場的に同じレベルの方が揃うようなシチュエーションで特に気付かされます。例えば、DX推進部の部長や製造部門の部長が同じプロジェクトに関わった際、誰が決定権や責任を持つかを明確にしておかなければ、揉めたり曖昧なまま進まなかったりします」と芳賀は説明します。

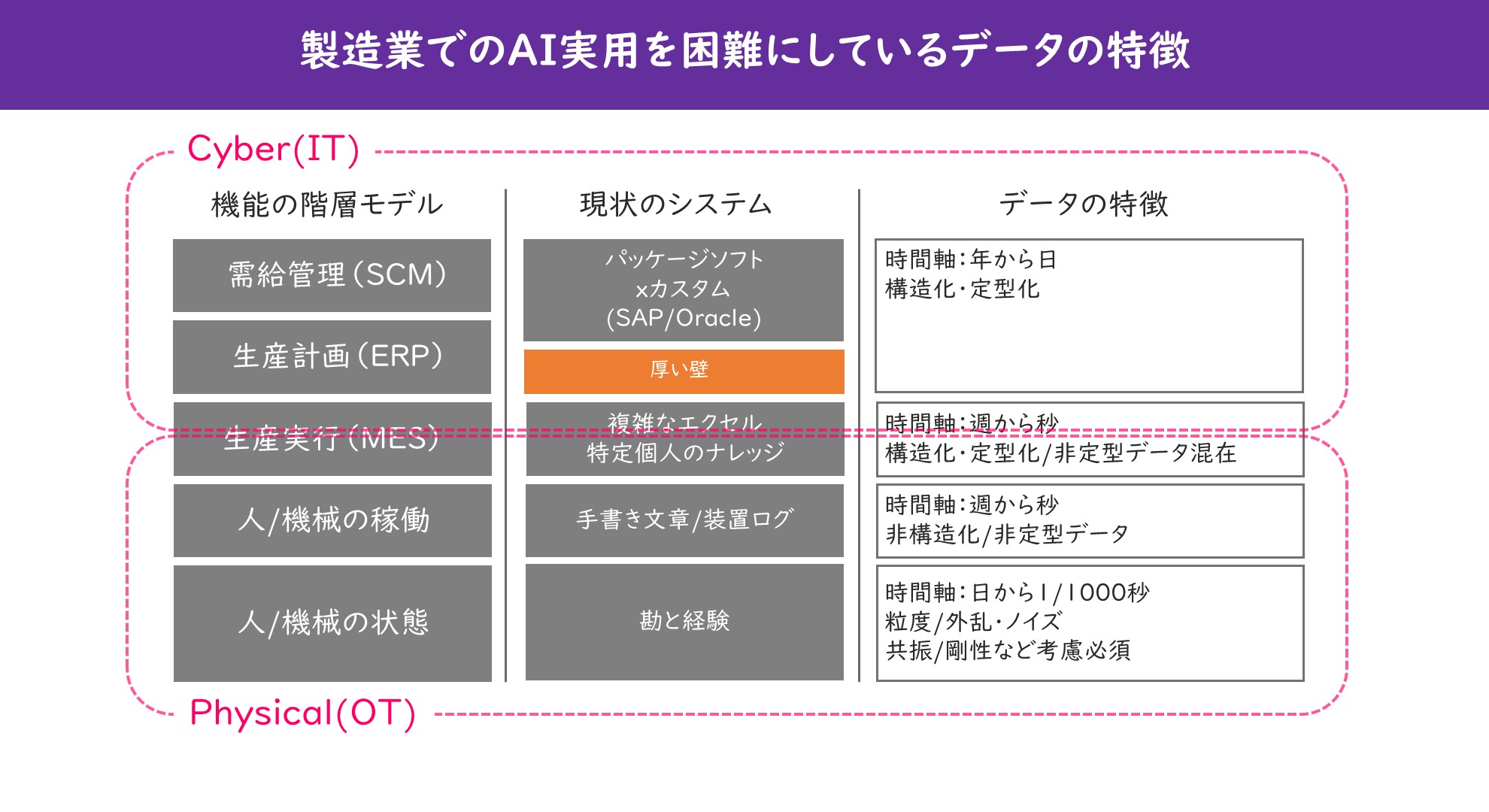

製造業ならではの難しいデータをどう扱うか

誰もがAIの実運用に最も重要なのはデータであると認識しながらもDXプロジェクトが頓挫してしまうこともあります。理由の大半は、しっかりとデータが取れていないことにあると言います。

「今後製造業がデータを有効活用して、発展・成長していくためには、データ収集は避けて通れない課題となっています。IT側から焦点を当てるのと、OT側から焦点を当てるのとでは、データの質と構造がまったく違うため、それぞれデータ取得方法と加工に工夫が必要ですし、それはとても“地道”で難しいからです。」(芳賀)

OT側はデータがあればいいという世界ではなく、ビッグデータ分析から入るロジックはほとんど通用しません。構造化されていない複雑なデータや粒度の細かいデータは、集めたからといって簡単に使えるものではないのです。

製造業は、他の分野に比べてデータを扱う難易度が高いという特徴があります

続けて芳賀は、データ収集における落とし穴は3つあると述べます。これらが不十分であると、データ確認フェーズでスタックしてしまいます。

1つ目は、「センシングに対する見識・検討」です。

「センサーを設置してデータを取ったものの、分析ができるレベルのデータではなかったというのはよく耳にする話ではないでしょうか。データが使えない可能性があるという前提でデータを収集し、アジャイル的に軌道修正する前提であれば問題ないのですが、気づくのが遅くなればなるほどプロジェクトに与えるインパクトは大きくなります。とりあえずデータを取っておけばいい、という考えが通用しないのがセンシングです。」(芳賀)

2つ目は、「設備装置ごとの差分想定」です。

「これは、設備の稼働データを収集するのは想定以上に苦労するということです。稼働情報など既存の機器の状態は取れて当然だと思われるかもしれません。特に現場から遠い経営陣などは、データ収集は難しくないと考える傾向にあります。「見る」という段階でお金も時間もかけたくないという本質的な要求があるためですが、実際には課題が発生するケースが多くあります。」(芳賀)

そして3つ目は、「データ収集の仕組みの検討」です。

「データマートとしてアウトプットされるデータの格納形式をしっかりと定めていくことが大切です。最初に必要なデータの項目と粒度を定義しないと始められないということではありませんが、少なくとも時系列や日付、ロット番号や製造型番の桁数などのイメージを持ったうえで仕組みを作ることが重要になってきます。工程内のデータは解像度が違うことも多いので、この定義付けは経験とセンスが問われます」(芳賀)

AIシステム管理で抑えるべきポイント

AIのシステムは、他のITシステムと異なる継続的な管理が必要です。AIの実運用システム管理について芳賀は以下のように話します。

「ITシステムは要件定義通りの設計開発を行って、要件定義に沿って保証するというのが一般的です。しかし、AIモデルが含まれると少し話が変わります。AIが期待通りに機能することを前提にシステム構築を行いますが、AIの精度保証は難しいものです。そこで、AIが期待通りの動きをしているかどうか、AIの精度やデータドリフトの監視が必要になります」(芳賀)

特に工場のデータは複雑で、さまざまな要因が影響しデータの傾向が変わる場合があります。その予期せぬ変化によって、AIが導き出す答えも変化していくため、完全におかしいと気づいた時にはもう手遅れです。そのためにも、しっかりと変化をトラッキングしていく必要があります。

また、変化に対応するためにはAIモデルのバージョン管理を行い、最適なモデルを適用していく仕組みも必要になります。この仕組みがないと、作った時点でいくら良い判定ができていたしても、時間の経過とともに精度が落ちていくだけのシステムになってしまうのです。

また芳賀は、「生産計画の高度化・省人化」「品質向上」「属人化された工程の標準化」を製造業DXの3大テーマとしてあげました。

「生産計画の高度化・省人化」については、急激な需要変動や多品種少量に対応するための高度化、計画業務へ携わる人員工数削減や標準化を目的としたDX化やAI活用のニーズが高まっています。

「最適な生産計画を作成するにあたり、 “何の”データを見て、“どのように”判断しているかが、人によって異なります。その属人化された作業を標準化するために、現状の業務プロセスを可視化し、判断ルールを作っていく作業が必要となります。現場の状況理解は、AIモデル開発や精度向上以上に大事な工程なのです」(芳賀)

現状分析は大切な工程ですが、解像度が荒くなりがちで、新しいシステムや仕組みを導入する根拠として使えないこともあります。

その要因としては、調査関係者の負荷が大きい、もしくは調査結果の信憑性に不安があるという点があります。現状分析・業務プロセス再設計のために、シミュレーターを使用した効率分析も有効なので、AI導入の前段で検討を進めるのがよいでしょう。

「品質向上」と「属人化された工程の標準化」については、個別に考えるのではなく、両方を一度に検討するのが最善です。品質管理は競争力の源泉であることから、多くの企業で大量に人的リソースをつぎ込んでいるでしょう。しかし、品質管理においても熟練者のノウハウに依存しているケースが多いため、継続的な維持・発展に対するリスクを感じている企業も増えています。

「品質向上に関しては、不良原因や品質予測、最適制御といったテーマがあげられます。例えば、不良原因分析を行い製造のノウハウに活かしたり、結果を予測することで検査工数を削減したり、最適なパラメーターを導き出すことにより適切な制御を行うなどがあります。最終的には最適な設定を機械にフィードバックさせる自動操業を視野に入れている企業もありますが、現状は人間との共存を前提としたシステムを構築するのが主流です。」(芳賀)

最後に「皆様が担っているミッションやプロジェクトは、簡単なものばかりではないと想像しています。陥りやすい課題を抑え、成功パターンを参考にしていただくことで、成功確度を少しでも上げていただきたいと思っています」として締めくくりました。